Gabatarwa

Lasers na diode suna aiki ta hanyar samar da wani abu mai kama da na diode.kunkuntar fitilahaske ta hanyar na'urar semiconductor.

Wannan fasaha tana samar datushen makamashi mai ƙarfiwanda za'a iya mayar da hankali kan yanke abubuwa kamar acrylic.

Sabanin na gargajiyaLasers na CO2Na'urorin laser na diode yawanci suna da tsada sosaiƙanƙanta kuma mai inganci - mai arahawanda hakan ya sanya su musammanmai kyaudon ƙananan bita da amfani a gida.

Fa'idodi

Yankewa daidai: Hasken da aka tattara yana ba da damar yin zane mai laushi da gefuna masu tsabta, waɗanda suke da mahimmanci don ayyuka masu kyau da cikakkun bayanai.

Ƙananan sharar kayan: Tsarin yankewa mai inganci yana haifar da ƙarancin kayan da suka rage.

Sadar da mai amfani: Yawancin tsarin laser na diode suna da software mai sauƙin amfani wanda ke sauƙaƙa tsarin ƙira da yankewa.

Inganci a cikin aiki - Farashi: Na'urorin laser na Diode suna amfani da ƙarancin wutar lantarki kuma suna da ƙarancin buƙatun kulawa idan aka kwatanta da sauran nau'ikan lasers.

Tsarin Mataki-mataki

1. Shirye-shiryen Zane: Yi amfani da manhajar da ta dace da laser (misali, Adobe Illustrator, AutoCAD) don ƙirƙirar ko shigo da ƙira mai tushen vector (SVG, DXF). Daidaita sigogin yankewa (sauri, ƙarfi, wucewa, tsawon mai da hankali) dangane da nau'in acrylic, kauri, da ƙarfin laser.

2. Shiri na Acrylic: Zaɓi zanen acrylic mai faɗi, wanda ba a naɗe ba. A tsaftace shi da sabulu mai laushi, a busar da shi sosai, sannan a shafa tef ɗin rufe fuska ko takarda don kare saman.

3. Saitin Laser: Ɗumama laser ɗin, tabbatar da daidaiton hasken da ya dace, da kuma tsaftace na'urorin gani. Yi gwajin yanke kayan da aka yayyanka don daidaita saitunan.

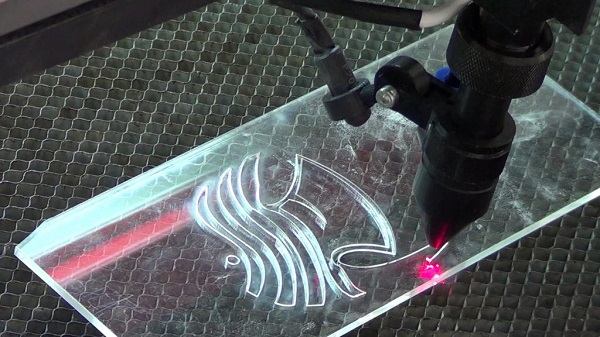

Samfurin Acrylic

Tsarin Yankan Laser Acrylic

4. Sanya Acrylic: A ɗaure takardar acrylic ɗin a kan gadon laser da tef ɗin rufe fuska, don tabbatar da sarari don motsin kan yanke.

5. Tsarin Yankewa: Fara yanke laser ta hanyar sarrafa software, sa ido sosai kan tsarin, kuma daidaita saitunan kamar yadda ake buƙata. Dakatar da shi idan matsaloli suka taso kuma a magance su kafin a ci gaba.

6. Bayan Sarrafawa: Bayan yankewa, tsaftace acrylic ɗin da goga mai laushi ko iska mai matsewa. Cire kayan rufe fuska sannan a shafa maganin gamawa (mai gogewa, mai goge wuta) idan ya cancanta.

Bidiyo masu alaƙa

Yadda za a Yanke Buga Acrylic

Injin yanke laser na ganiKyamarar CCDtsarin ganewa yana bayar damai inganci da arahamadadin firintar UV don yanke fasahar acrylic da aka buga.

Wannan hanyaryana sauƙaƙa tsarin, kawar da buƙatardon daidaitawar yanke laser da hannu.

Ya dace da duka biyunaiwatar da aikin cikin saurida kuma samar da kayayyaki a fannin masana'antukayan daban-daban.

Kana son ƙarin sani game daYankan Laser?

Fara Tattaunawa Yanzu!

Nasihu

Nasihu kan Shiri

Zaɓi Acrylic Mai Dacewa: Acrylic masu haske da shuɗi na iya haifar da ƙalubale ga lasers na diode domin ba sa shan hasken yadda ya kamata. Duk da haka, acrylic baƙi yana da sauƙin yankewa.

Daidai - daidaita Mayar da Hankali: Daidaita hasken laser a saman kayan yana da matuƙar muhimmanci. Tabbatar an daidaita tsawon hasken daidai da kauri na acrylic.

Zaɓi Saitunan Wuta da Sauri Masu Dacewa: Lokacin yanke acrylic, lasers na diode gabaɗaya suna aiki da kyau tare da ƙarancin ƙarfin aiki da raguwar gudu.

Nasihu kan Aiki

Yanke gwaji: Kafin yin samfurin ƙarshe, koyaushe gwada yanke sharar don nemo wurin da ya dace.

Amfani da kayan aikin taimako: Amfani da murfin wutar lantarki na iya rage harshen wuta da hayaki, wanda ke haifar da gefuna masu tsabta.

Tsaftace ruwan tabarau na laser: Tabbatar cewa ruwan tabarau na laser ba shi da tarkace, domin duk wani cikas zai iya yin mummunan tasiri ga ingancin yankewa.

Nasihu kan Tsaro

Gashin Ido Masu Kariya: Kullum ka sanya gilashin kariya na laser mai dacewa don kare idanunka daga hasken da ke haskakawa.

Tsaron Gobara: A ajiye na'urar kashe gobara kusa, domin acrylic da aka yanke zai iya haifar da hayaki mai kama da wuta.

Tsaron Lantarki: Tabbatar cewa an yi amfani da na'urar laser diode ɗinka yadda ya kamata domin guje wa haɗarin wutar lantarki.

A yanka a kan takardar farin acrylic

Tambayoyin da ake yawan yi

Yawancin acrylic ana iya yanke su ta hanyar laser. Duk da haka, abubuwa kamarlauni da nau'inzai iya yin tasiri ga tsarin.

Misali, na'urorin laser masu haske na shuɗi ba su da ikon yanke acrylic mai shuɗi ko mai haske.

Yana da mahimmanci agwada takamaimanacrylic da kake shirin amfani da shi.

Wannan yana tabbatar da cewa yana dacewa da na'urar yanke laser ɗinku kuma yana iya cimma sakamakon da ake so.

Domin laser ya sassaka ko ya yanke abu, kayan dole ne su sha ƙarfin hasken laser ɗin.

Wannan makamashi yana tururiabu, wanda ke ba da damar yanke shi.

Duk da haka, lasers na diode suna fitar da haske a tsawon tsayin daka na 100 zuwa 100.450nm, wanda acrylic mai tsabta da sauran kayan haske ba za su iya sha ba.

Saboda haka, hasken laser yana wucewa ta cikin acrylic mai haske ba tare da ya shafe shi ba.

A gefe guda kuma, kayan duhu suna shan hasken laser daga masu yanke laser diodeya fi sauƙi.

Wannan shine dalilin da yasa laser diode zai iya yanke wasu kayan acrylic masu duhu da kuma marasa haske.

Yawancin lasers na diode suna iya jure zanen acrylic tare da kauri har zuwa6 mm.

Don zanen gado mai kauri,wucewa da yawa ko kuma lasers masu ƙarfi fiye da hakaana iya buƙata.

Ba da shawarar Injinan

Wurin Aiki (W *L)Girman: 600mm * 400mm (23.6” * 15.7”)

Ƙarfin Laser: 60W

Wurin Aiki (W *L)Girman: 1300mm * 900mm (51.2” * 35.4”)

Ƙarfin Laser: 100W/150W/300W

Lokacin Saƙo: Afrilu-30-2025