Isingeniso

Ama-laser e-diode asebenza ngokukhiqizaumsebe omncanekokukhanya nge-semiconductor.

Lobu buchwepheshe buhlinzekaumthombo wamandla agxilileokungagxilwa ekusikeni izinto ezifana ne-acrylic.

Ngokungafani nokuvamileAma-laser e-CO2, ama-diode lasers ngokuvamile avame kakhuluincane futhi iyasebenza kahle, okubenza babe ikakhulukazikukhangakwezindawo zokusebenzela ezincane kanye nokusetshenziswa ekhaya.

Izinzuzo

Ukusika okunembile: Ugongolo oluhlanganisiwe luvumela amaphethini abucayi kanye nemiphetho ehlanzekile, okubalulekile emisebenzini ecacile nenemininingwane.

Imfucuza yezinto eziphansi: Inqubo yokusika ephumelelayo iholela ekutheni kube nezinto ezisele kancane.

Ubungane bomsebenzisiIzinhlelo eziningi ze-laser ze-diode zifakwe isofthiwe elula ukuyisebenzisa eyenza kube lula ukuklama nokusika izinqubo.

Ukusebenza kahle kwezindleko: Ama-laser e-diode asebenzisa ugesi omncane futhi anezidingo ezincane zokunakekelwa uma kuqhathaniswa nezinye izinhlobo zama-laser.

Inqubo Yesinyathelo Ngesinyathelo

1. Ukulungiselela Umklamo: Sebenzisa isofthiwe ehambisana ne-laser (isb., i-Adobe Illustrator, i-AutoCAD) ukudala noma ukungenisa umklamo osekelwe ku-vector (SVG, DXF). Lungisa amapharamitha okusika (isivinini, amandla, amaphasi, ubude obuqondile) ngokusekelwe ohlotsheni lwe-acrylic, ukujiya, kanye nekhono le-laser.

2. Ukulungiselela i-Acrylic: Khetha amashidi e-acrylic ayisicaba, angasongwanga. Hlanza ngensipho ethambile, womise kahle, bese ufaka i-masking tape noma iphepha ukuvikela izindawo.

3. Ukusethwa kwe-Laser: Fudumeza i-laser, uqinisekise ukuthi imisebe iqondaniswa kahle, futhi uhlanze i-optics. Yenza isivivinyo sokusika ezintweni ezilahliwe ukuze ulinganise izilungiselelo.

Umkhiqizo we-Acrylic

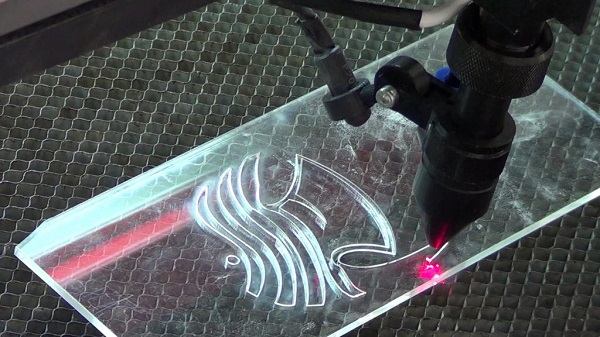

Inqubo Yokusika I-Laser Acrylic

4. Ukubekwa kwe-Acrylic: Bopha ishidi le-acrylic embhedeni we-laser nge-masking tape, uqinisekise indawo yokuhamba kwekhanda elisikayo.

5. Inqubo Yokusika: Qala ukusika nge-laser ngezilawuli zesofthiwe, qapha inqubo eduze, bese ulungisa izilungiselelo njengoba kudingeka. Misa isikhashana uma kuvela izinkinga bese uzixazulula ngaphambi kokuqhubeka.

6. Ngemva Kokucubungula: Ngemva kokusika, hlanza i-acrylic ngebhulashi elithambile noma ngomoya ocindezelwe. Susa izinto zokufihla bese ufaka ukwelashwa kokuqeda (i-polishing compound, i-flame polishing) uma kudingeka.

Amavidiyo Ahlobene

Indlela Yokusika I-Acrylic Ephrintiwe

Umshini wokusika we-laser obonayoIkhamera ye-CCDuhlelo lokuqashelwa lunikezakuqiza kahleesikhundleni sephrinta ye-UV yokusika imisebenzi yobuciko ye-acrylic ephrintiwe.

Le ndlelakwenza inqubo ibe lula, ukuqeda isidingoukuze kulungiswe umshini wokusika nge-laser ngesandla.

Ifanele kokubiliukufezwa kwephrojekthi okusheshayokanye nokukhiqizwa kwezinga lezimboni kwe-izinto ezahlukahlukene.

Ufuna Ukwazi Okwengeziwe NgalokhuUkusika Nge-Laser?

Qala Ingxoxo Manje!

Amathiphu

Amathiphu Okulungiselela

Khetha i-Acrylic Efanele: Ama-acrylic acacile naluhlaza okwesibhakabhaka angaba yinselele kuma-diode lasers njengoba engamunci kahle ukukhanya. Kodwa-ke, i-acrylic emnyama ivame ukusika kalula.

Lungisa kahle i-Focus: Ukugxila kahle umsebe we-laser ebusweni bento kubalulekile. Qiniseka ukuthi ubude be-focal bulungiswa ngokuhambisana nobukhulu be-acrylic.

Khetha Izilungiselelo Zamandla Nesivinini Ezifanele: Uma usika i-acrylic, ama-diode lasers ngokuvamile asebenza kahle ngamazinga aphansi amandla kanye nesivinini esincishisiwe.

Amathiphu Okusebenza

Ukusika ukuhlolwa: Ngaphambi kokwenza umkhiqizo wokugcina, hlola njalo ukusika izinto ezilahliwe ukuze uthole indawo efanelekile.

Ukusebenzisa imishini yokusizaUkusebenzisa i-range hood kunganciphisa amalangabi kanye nentuthu, okuholela emaphethelweni ahlanzekile.

Hlanza ilensi yelaser: Qinisekisa ukuthi ilensi ye-laser ayinazo izinsalela, njengoba noma yiziphi izithiyo zingaba nomthelela omubi ekhwalithini yokusika.

Amathiphu Okuphepha

Izibuko Ezivikelayo: Gqoka njalo izibuko zokuphepha ze-laser ezifanele ukuvikela amehlo akho ekukhanyeni okukhanyayo.

Ukuphepha Komlilo: Yiba nesicisha-mlilo esiseduze, njengoba ukusika i-acrylic kungakhipha umusi ovuthayo.

Ukuphepha Kukagesi: Qinisekisa ukuthi i-laser yakho ye-diode isekelwe kahle ukuze ugweme izingozi zikagesi.

Sika Eshidini Elimhlophe Le-Acrylic

Imibuzo Evame Ukubuzwa

Iningi le-acrylic lingasikwa nge-laser. Kodwa-ke, izici ezifanaumbala nohlobokungathonya inqubo.

Isibonelo, ama-laser e-diode aluhlaza okwesibhakabhaka awakwazi ukusika i-acrylic eluhlaza okwesibhakabhaka noma ecacile.

Kubalulekile ukuthihlola okuthilei-acrylic ohlela ukuyisebenzisa.

Lokhu kuqinisekisa ukuthi kuyahambisana nomsiki wakho we-laser futhi kungafinyelela imiphumela oyifunayo.

Ukuze i-laser iqophe noma isike izinto, izinto kumele zimunce amandla okukhanya e-laser.

Lawa mandla aphefumulaizinto, okwenza ukuthi inqunywe.

Kodwa-ke, ama-laser e-diode akhipha ukukhanya nge-wavelength ye-450nm, okuyinto i-acrylic ecacile nezinye izinto ezibonakalayo ezingenakukwazi ukuyimunca.

Ngakho-ke, ukukhanya kwe-laser kudlula ku-acrylic ecacile ngaphandle kokuyithinta.

Ngakolunye uhlangothi, izinto ezimnyama zimunca ukukhanya kwe-laser okuvela kubasiki be-laser be-diodekalula kakhulu.

Yingakho ama-laser e-diode engasika ezinye izinto ze-acrylic ezimnyama nezingabonakali.

Ama-laser amaningi e-diode angaphatha amashidi e-acrylic anobukhulu obufika ku-6 mm.

Ukuze uthole amashidi amakhulu,amaphasi amaningi noma ama-laser anamandla kakhulukungase kudingeke.

Ncoma Imishini

Indawo Yokusebenza (W *L): 600mm * 400mm (23.6” * 15.7”)

Amandla e-Laser: 60W

Indawo Yokusebenza (W *L): 1300mm * 900mm (51.2” * 35.4”)

Amandla e-Laser: 100W/150W/300W

Isikhathi sokuthunyelwe: Ephreli-30-2025