Introduction

Diode lasers function by producing a narrow beam of light through a semiconductor.

This technology provides a concentrated energy source that can be focused to cut through materials such as acrylic.

Unlike conventional CO2 lasers, diode lasers are typically more compact and cost - effective, which makes them especially attractive for small workshops and home use.

Advantages

Accurate cutting: The concentrated beam enables delicate patterns and clean edges, crucial for fine - detailed tasks.

Lower material waste: The effective cutting process results in less residual material.

User - friendliness: Many diode laser systems are equipped with easy - to - use software that streamlines the design and cutting procedures.

Cost - effectiveness in operation: Diode lasers use less electricity and have lower upkeep needs compared to other types of lasers.

Step-by-step Process

1. Design Preparation: Use laser-compatible software (e.g., Adobe Illustrator, AutoCAD) to create or import a vector-based design (SVG, DXF). Adjust cutting parameters (speed, power, passes, focal length) based on acrylic type, thickness, and laser capabilities.

2. Acrylic Preparation: Select flat, unwrapped acrylic sheets. Clean with mild soap, dry thoroughly, and apply masking tape or paper to protect surfaces.

3. Laser Setup: Warm up the laser, ensure proper beam alignment, and clean optics. Perform a test cut on scrap material to calibrate settings.

Acrylic Product

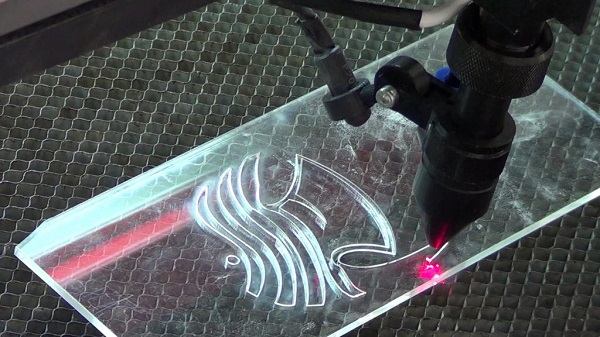

Laser Cutting Acrylic Process

4. Acrylic Placement: Secure the acrylic sheet to the laser bed with masking tape, ensuring space for the cutting head's movement.

5. Cutting Process: Start the laser cutting via software controls, monitor the process closely, and adjust settings as needed. Pause if issues arise and address them before continuing.

6. Post-Processing: After cutting, clean the acrylic with a soft brush or compressed air. Remove masking materials and apply finishing treatments (polishing compound, flame polishing) if necessary.

Related Videos

How to Cut Printed Acrylic

A vision laser cutting machine's CCD camera recognition system offers a cost-effective alternative to a UV printer for cutting printed acrylic crafts.

This method simplifies the process, eliminating the need for manual laser cutter adjustments.

It's suitable for both quick project realization and industrial-scale production of diverse materials.

Want To Know More About Laser Cutting?

Start a Conversation Now!

Tips

Preparation Tips

Pick the Suitable Acrylic: Clear and blue acrylics can pose challenges for diode lasers as they don't effectively absorb the light. However, black acrylic tends to cut very easily.

Fine - tune the Focus: Correctly focusing the laser beam on the material's surface is vital. Make sure the focal length is adjusted in line with the acrylic's thickness.

Choose Suitable Power and Speed Settings: When cutting acrylic, diode lasers generally perform well with lower power levels and reduced speeds.

Operation Tips

Test cutting: Before making the final product, always test cut the waste materials to find the ideal setting.

Using auxiliary equipment: Using a range hood can reduce flames and smoke, resulting in cleaner edges.

Clean the laser lens: Ensure that the laser lens is free of debris, as any obstacles can have a negative impact on the cutting quality.

Safety Tips

Protective Eyewear: Always wear suitable laser safety glasses to protect your eyes from reflected light.

Fire Safety: Have a fire extinguisher close at hand, as cutting acrylic can generate flammable fumes.

Electrical Safety: Ensure your diode laser is properly grounded to avoid electrical risks.

Cut On The White Acrylic Sheet

FAQs

Most acrylic can be laser-cut. However, factors like color and type can influence the process.

For instance, blue-light diode lasers are not capable of cutting blue or transparent acrylic.

It is important to test the specific acrylic you plan to use.

This ensures it is compatible with your laser cutter and can achieve the desired results.

For a laser to engrave or cut material, the material must absorb the laser's light energy.

This energy vaporizes the material, enabling it to be cut.

However, diode lasers emit light at a wavelength of 450nm, which clear acrylic and other transparent materials can’t absorb.

Thus, the laser light passes through clear acrylic without affecting it.

On the other hand, dark materials absorb the laser light from diode laser cutters much more easily.

This is the reason diode lasers can cut some dark and opaque acrylic materials.

Most diode lasers can handle acrylic sheets with a thickness of up to 6 mm.

For thicker sheets, multiple passes or more powerful lasers might be needed.

Recommend Machines

Working Area (W *L): 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power: 100W/150W/300W

Post time: Apr-30-2025