Ukucocwa kwelaser yemizi-mveliso yinkqubo yokudubula umqadi welaser kumphezulu oqinileyo ukuze ucoceke ngelaser kwaye ususe into engafunekiyo. Ekubeni ixabiso lomthombo welaser yefayibha liye lehla kakhulu kwiminyaka embalwa edlulileyo, abacoci belaser—benzelwe ukunceda abasebenzisi ukuba bacoce ngelaser ngokufanelekileyo—bahlangabezana neemfuno zemarike ezibanzi ngakumbi kunye namathuba asetyenzisiweyo, njengokucoca iinkqubo zokubumba inaliti, ukususa iifilimu ezincinci okanye iindawo ezifana neoyile, kunye negrisi, kunye nezinye ezininzi. Kweli nqaku, siza kugubungela ezi zihloko zilandelayo:

Uluhlu Lomxholo(cofa ukuze ufumane indawo ngokukhawuleza ⇩)

Yintoni ukuCoca ngeLaser?

Ngokwesiko, ukususa umhlwa, ipeyinti, i-oxide, kunye nezinye izinto ezingcolisayo kumphezulu wesinyithi, ukucoca ngoomatshini, ukucoca ngamakhemikhali, okanye ukucoca nge-ultrasound kunokusetyenziswa. Ukusetyenziswa kwezi ndlela kunqongophele kakhulu ngokwemeko-bume kunye neemfuno zokuchaneka okuphezulu.

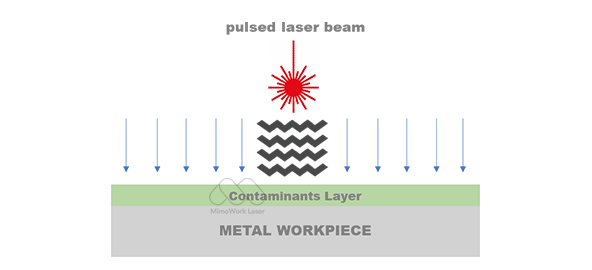

Inkqubo yokucoca ngeLaser.

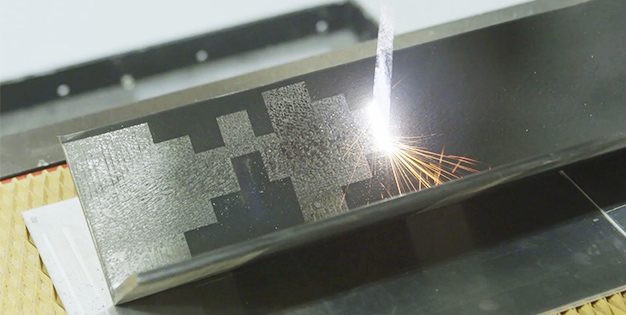

Kwiminyaka yoo-1980, izazinzulu zafumanisa ukuba xa zikhanyisa umphezulu wesinyithi onomhlwa ngamandla elaser axineneyo, into ekhanyiswayo idlula kuthotho lweempendulo ezintsonkothileyo zomzimba nezekhemikhali ezifana nokungcangcazela, ukunyibilika, ukunyibilika, kunye nokutsha. Ngenxa yoko, ukungcola kuyasuswa kumphezulu wezinto. Le ndlela ilula kodwa isebenzayo yokucoca yilaser, eye yathatha indawo yeendlela zokucoca zemveli kwiindawo ezininzi ngeenzuzo zayo ezininzi, ibonisa amathuba abanzi ekamva.

Zisebenza njani iiLaser Cleaners?

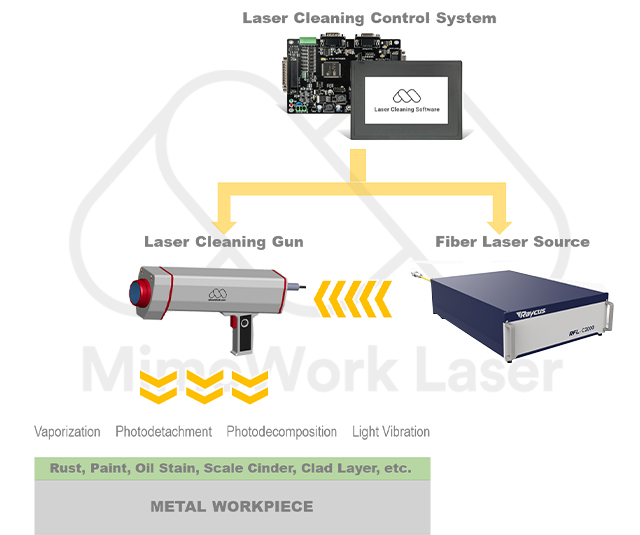

Umatshini wokucoca nge-laser

Izicoci zelaser zenziwe ngamacandelo amane:umthombo we-fiber laser (i-continuous okanye i-pulse laser), ibhodi yokulawula, umpu we-laser ophathwayo, kunye ne-water chiller yobushushu obungaguqukiyoIbhodi yokulawula ukucoca nge-laser isebenza njengengqondo yomatshini wonke kwaye inika i-fibre laser generator kunye ne-laser gun ephathwayo ukuze ilandelelwe.

Ijenereyitha yelaser yefayibha ivelisa ukukhanya kwelaser okuxineneyo okuphezulu okudlula kwiFiber ye-conduction medium ukuya kwi-laser gun ephathwayo. I-scan galvanometer, nokuba yi-uniaxial okanye i-biaxial, ehlanganiswe ngaphakathi kwi-laser gun ibonisa amandla okukhanya kumaleko wokungcola we-workpiece. Ngokudityaniswa kwe-reactions zomzimba nezekhemikhali, umhlwa, ipeyinti, ukungcola okunamafutha, umaleko wokugquma, kunye nolunye ungcoliseko zisuswa ngokulula.

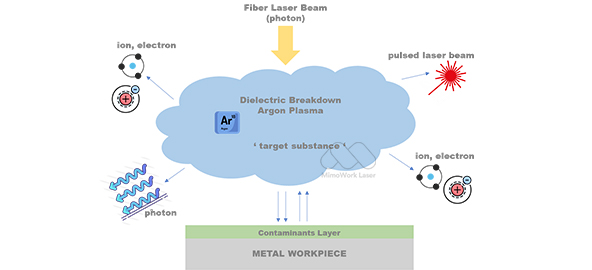

Masingene kwiinkcukacha ezithe vetshe ngale nkqubo. Iimpendulo ezintsonkothileyo ezibandakanyekayo ekusebenziseniukungcangcazela kwe-laser pulse, ukwandiswa kobushushuyamasuntswana akhanyiswe ngemitha,ukubola kwe-molecularutshintsho lwesigaba, okanyeisenzo sabo esidibeneyoukuze koyiswe amandla okubopha phakathi kokungcola nomphezulu wesixhobo somsebenzi. Izinto ekujoliswe kuzo (umaleko womphezulu oza kususwa) zifudunyezwa ngokukhawuleza ngokufunxa amandla e-laser beam kwaye zihlangabezana neemfuno ze-sublimation ukuze ukungcola okuvela kumphezulu kunyamalale ukuze kufezekiswe iziphumo zokucoca. Ngenxa yoko, umphezulu we-substrate awufunxi amandla e-ZERO, okanye amandla amancinci kakhulu, ukukhanya kwe-fiber laser akuyi kuyonakalisa konke konke.

Funda ngakumbi malunga nolwakhiwo kunye nomgaqo we-Handheld Laser Cleaner

Iimpendulo Ezintathu Zokucoca NgeLaser

1. Ukunciphisa i-sublimation

Ukwakheka kweekhemikhali zezinto ezisisiseko kunye nongcoliseko kwahlukile, kwaye kunjalo nangesantya sokufunxwa kwelaser. Isiseko sesiseko sibonisa ngaphezulu kwe-95% yokukhanya kwelaser ngaphandle komonakalo, ngelixa ungcoliseko lufunxa uninzi lwamandla elaser kwaye lufikelele kubushushu be-sublimation.

Umzobo weNdlela yokuCoca iLaser

2. Ukwandiswa kobushushu

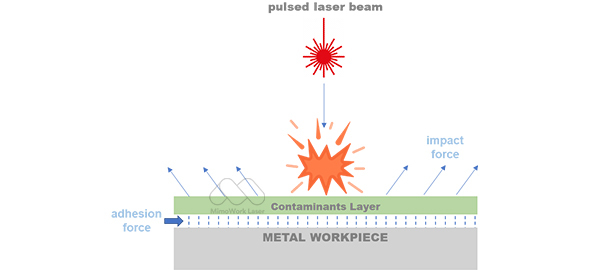

Amasuntswana angcolisayo afunxa amandla obushushu aze akhule ngokukhawuleza ade aqhume. Impembelelo yokuqhuma igqitha amandla okunamathela (amandla okutsalana phakathi kwezinto ezahlukeneyo), kwaye ngaloo ndlela amasuntswana angcolisayo asuswa kumphezulu wesinyithi. Ngenxa yokuba ixesha lokukhanyiswa kwelaser lifutshane kakhulu, linokuvelisa ngoko nangoko ukukhawulezisa okukhulu kwamandla okuqhuma, okwaneleyo ukubonelela ngokukhawulezisa okwaneleyo kwamasuntswana amancinci ukuba asuke ekunamatheleni kwezinto ezisisiseko.

Umzobo woNxibelelwano lwaMandla oCoca iLaser etyhalwayo

3. Ukungcangcazela kweLaser Pulse

Ububanzi be-pulse yomqadi we-laser buncinci kakhulu, ngoko ke isenzo esiphindaphindwayo se-pulse siya kudala ukungcangcazela kwe-ultrasonic ukucoca indawo yokusebenza, kwaye i-shock wave iya kuqhekeza amasuntswana angcolisayo.

Indlela yokucoca imiqadi yelaser etyhalwayo

Iingenelo zoMatshini wokucoca iFiber Laser

Ngenxa yokuba ukucoca nge-laser akudingi zinyibilikisi zeekhemikhali okanye ezinye izinto ezisetyenziswayo, kunobuhlobo nokusingqongileyo, kukhuselekile ukuyisebenzisa, kwaye kuneengenelo ezininzi:

✔Umgubo wesolider ikakhulu yinkunkuma emva kokucocwa, inomthamo omncinci, kwaye kulula ukuyiqokelela nokuyiphinda isetyenziswe

✔Umsi kunye nothuthu oluveliswa yi-fiber laser kulula ukulukhupha ngomatshini wokukhupha umsi, kwaye alunzima kwimpilo yabantu.

✔Ukucoca okungenazo iintambo, akukho mithombo yeendaba eseleyo, akukho ngcoliseko lwesibini

✔Ukucoca kuphela indawo ekujoliswe kuyo (umhlwa, ioyile, ipeyinti, ugqubuthelo), akuyi konakalisa umphezulu we-substrate

✔Umbane kuphela kweendleko zokusetyenziswa, iindleko zokusebenza eziphantsi, kunye nokugcinwa kwempahla.

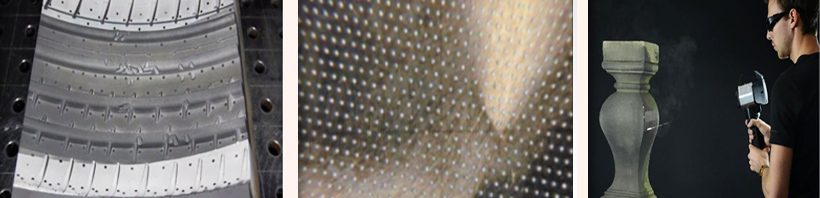

✔Ifanelekile kwiindawo ezilukhuni ukufikelela kuzo kunye nesakhiwo esintsonkothileyo sezinto zakudala

✔Irobhothi yokucoca nge-laser ngokuzenzekelayo ayinyanzelekanga, ithatha indawo yokwenziwa

Ukususa izinto ezingcolisayo ezifana nomhlwa, ukungunda, ipeyinti, iilebheli zephepha, iipolymers, iplastiki, okanye nayiphi na enye into engaphezulu, iindlela zemveli - ukuqhumisa imidiya kunye nokugrumba ngeekhemikhali - zifuna ukuphathwa okukhethekileyo kunye nokulahla imidiya kwaye zinokuba yingozi kakhulu kwindalo esingqongileyo nakubasebenzi ngamanye amaxesha. Itheyibhile engezantsi idwelisa umahluko phakathi kokucoca nge-laser kunye nezinye iindlela zokucoca kwimizi-mveliso.

| Ukucoca ngeLaser | Ukucoca iikhemikhali | Ukupholisha ngoomatshini | Ukucoca Umkhenkce Owomileyo | Ukucoca nge-Ultrasonic | |

| Indlela yokucoca | I-Laser, ayiqhagamshelani | Isinyibilikisi sekhemikhali, ukudibana ngqo | Iphepha elirhabaxa, ukudibana ngqo | Umkhenkce owomileyo, awuchukumisi | Isepha yokucoca, ukudibana ngqo |

| Umonakalo wezinto eziphathekayo | No | Ewe, kodwa kunqabile | Ewe | No | No |

| Ukusebenza kakuhle kokucoca | Phezulu | Iphantsi | Iphantsi | Iphakathi | Iphakathi |

| Ukusetyenziswa | Umbane | Isinyibilikisi seKhemikhali | Iphepha Elirhabaxa/ Ivili Elirhabaxa | Umkhenkce owomileyo | Isicoci seSolvent |

| Isiphumo sokucoca | ukungabi nabala | rhoqo | rhoqo | ibalasele kakhulu | ibalasele kakhulu |

| Umonakalo kwiNdalo | Ilungele okusingqongileyo | Ingcolisiwe | Ingcolisiwe | Ilungele okusingqongileyo | Ilungele okusingqongileyo |

| Umsebenzi | Kulula kwaye kulula ukuyifunda | Inkqubo enzima, kufuneka umqhubi onobuchule | kufuneka umqhubi onobuchule | Kulula kwaye kulula ukuyifunda | Kulula kwaye kulula ukuyifunda |

Ukukhangela Indlela Efanelekileyo Yokususa Izinto Ezingcolileyo Ngaphandle Kokonakalisa I-Substrate

▷ Umatshini wokucoca ngeLaser

Iindlela Zokucoca Ngelaser

• isikhunta sokucoca nge-laser

• uburhabaxa bomphezulu ngelaser

• into yokucoca nge-laser

• ukususwa kwepeyinti nge-laser…

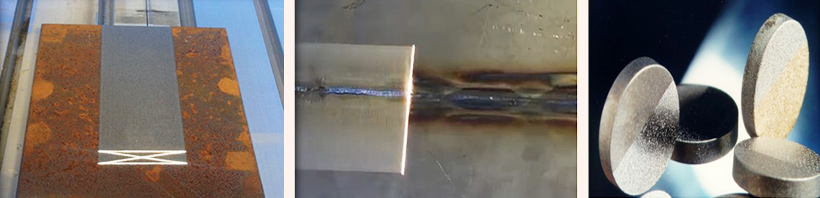

Ukucoca ngeLaser Kusetyenziswa Ngokwenyani

Imibuzo ebuzwa rhoqo

Ewe, ikhuselekile ngokupheleleyo. Isitshixo sikwizinga ezahlukeneyo zokufunxwa kwelaser: izinto ezisisiseko zibonisa ngaphezulu kwe-95% yamandla elaser, zifunxa ubushushu obuncinci okanye bungabikho. Izinto ezingcolisayo (umhlwa, ipeyinti) zifunxa uninzi lwamandla endaweni yoko. Ixhaswa lulawulo oluchanekileyo lwe-pulse, le nkqubo ijolise kuphela kwizinto ezingafunekiyo, ithintela naluphi na ukonakala kwisakhiwo se-substrate okanye umgangatho womphezulu.

Iphatha uluhlu olubanzi lwezinto ezingcolisa amashishini ngokufanelekileyo.

- Umhlwa, ii-oxides, kunye nokugqwala kwiindawo zesinyithi.

- Ipeyinti, iipeyinti, kunye neefilimu ezincinci ezenziwe ngezinto zokusebenza.

- Ioyile, igrisi, kunye namabala kwiinkqubo zokubumba ngenaliti.

- Iintsalela zokuwelda kunye neebhar ezincinci ngaphambi/semva kokuwelda.

- Ayipheleli nje kwiisinyithi—ikwasebenza nakwiindawo ezithile ezingezizo zesinyithi kwizinto ezingcolisa ukukhanya.

Ingcono kakhulu kwindalo kunokucoca ngeekhemikhali okanye ngoomatshini.

- Akukho zinyibilikisi zamakhemikhali (ezithintela ungcoliseko lomhlaba/lwamanzi) okanye izinto ezirhabaxa ezisetyenziswayo (ezinciphisa inkunkuma).

- Inkunkuma ikakhulu yimpuphu encinci eqinileyo okanye umsi omncinci, okulula ukuwuqokelela ngee-fume extractors.

- Isebenzisa umbane kuphela—akukho mfuneko yokulahla inkunkuma enobungozi, ithobela imigangatho engqongqo yokusingqongileyo kwemizi-mveliso.

Ixesha lokuthumela: Julayi-08-2022