Ukuhlanzwa nge-laser yezimboni kuyinqubo yokudubula umsebe we-laser endaweni eqinile ukuze kuhlanzwe nge-laser futhi kususwe into engafuneki. Njengoba intengo yomthombo we-laser ye-fiber yehle kakhulu eminyakeni embalwa edlule, abahlanzi be-laser—abaklanyelwe ukusiza abasebenzisi ukuhlanza nge-laser ngempumelelo—bahlangabezana nezidingo zemakethe ezibanzi kakhulu kanye namathemba asetshenziswayo, njengokuhlanza izinqubo zokubumba umjovo, ukususa amafilimu amancane noma izindawo ezifana namafutha, namafutha, nokunye okuningi. Kulesi sihloko, sizoxoxa ngezihloko ezilandelayo:

Uhlu Lokuqukethwe(chofoza ukuze uthole ngokushesha ⇩)

Kuyini Ukuhlanza Nge-Laser?

Ngokwesiko, ukuze kususwe ukugqwala, upende, i-oxide, kanye nezinye izinto ezingcolisayo ebusweni bensimbi, kungasebenza ukuhlanza ngemishini, ukuhlanza ngamakhemikhali, noma ukuhlanza nge-ultrasonic. Ukusetshenziswa kwalezi zindlela kunqunyelwe kakhulu ngokwendawo kanye nezidingo zokunemba okuphezulu.

Inqubo Yokuhlanza Nge-Laser.

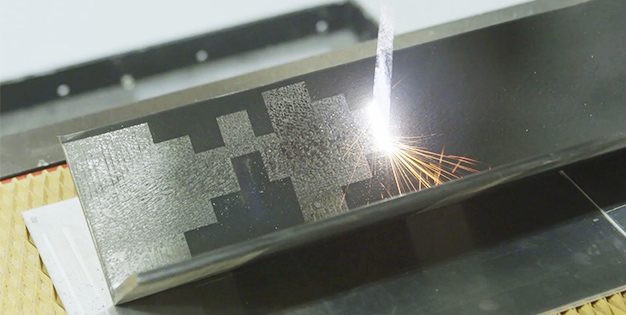

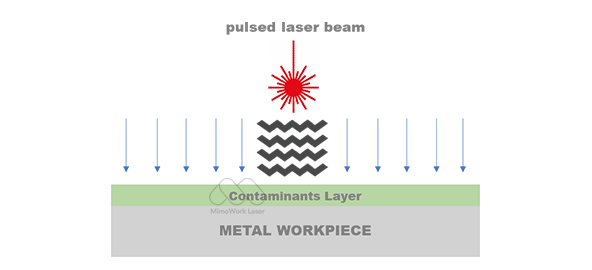

Ngawo-1980, ososayensi bathola ukuthi lapho bekhanyisa ubuso bensimbi obugqwalile ngamandla e-laser agxile kakhulu, into ekhanyiswe ngemisebe idlula ochungechungeni lwezimo eziyinkimbinkimbi zomzimba nezamakhemikhali njengokudlidliza, ukuncibilika, ukuncibilika, kanye nokusha. Ngenxa yalokho, ukungcola kuyasuswa ebusweni bezinto ezibonakalayo. Le ndlela elula kodwa ephumelelayo yokuhlanza iwukuhlanza nge-laser, okuye kancane kancane kwathatha indawo yezindlela zokuhlanza zendabuko emikhakheni eminingi ngezinzuzo eziningi zayo, okubonisa amathuba abanzi esikhathi esizayo.

Zisebenza Kanjani Izihlanzi Ze-Laser?

Umshini Wokuhlanza Nge-Laser

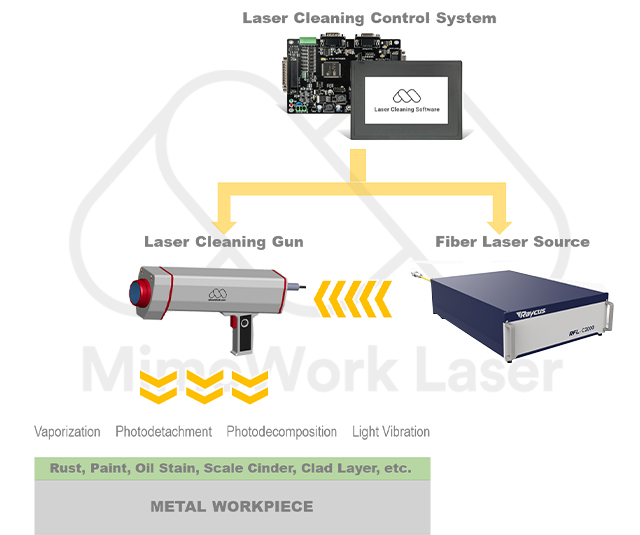

Izihlanzi ze-laser zakhiwe ngezingxenye ezine:umthombo we-fiber laser (i-continuous noma i-pulse laser), ibhodi lokulawula, isibhamu se-laser esiphathwa ngesandla, kanye ne-water chiller yokushisa okungaguqukiIbhodi lokulawula ukuhlanza nge-laser lisebenza njengobuchopho bomshini wonke futhi linikeza ijeneretha ye-laser ye-fiber kanye nesibhamu se-laser esiphathwa ngesandla ukuhleleka.

Ijeneretha yelaser yefayibha ikhiqiza ukukhanya kwelaser okugxile kakhulu okudluliswa nge-conduction medium Fiber kuya esibhamuni selaser esiphathwayo. I-scan galvanometer, kungaba yi-uniaxial noma i-biaxial, ehlanganiswe ngaphakathi kwesibhamu selaser ibonisa amandla okukhanya engqimbeni yokungcola yento yokusebenza. Ngokuhlanganiswa kokusabela ngokomzimba namakhemikhali, ukugqwala, upende, ukungcola okunamafutha, ungqimba lokumboza, nokunye ukungcola kususwa kalula.

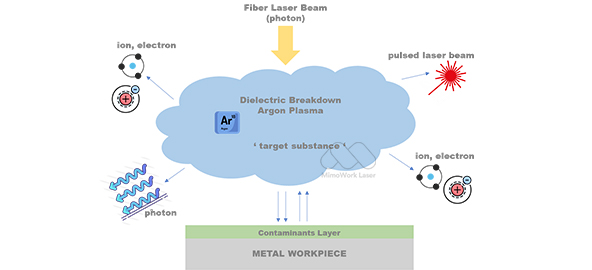

Ake sichaze kabanzi ngale nqubo. Izimpendulo eziyinkimbinkimbi ezihilelekile ekusetshenzisweni kweukudlidliza kwe-laser pulse, ukwanda kokushisakwezinhlayiya ezikhanyisiwe,ukubola kwe-moleculeushintsho lwesigaba, nomaisenzo sabo esihlangeneukuze kunqotshwe amandla okubopha phakathi kokungcola kanye nobuso bento yokusebenza. Izinto eziqondiwe (ungqimba olungaphezulu oluzosuswa) zishiswa ngokushesha ngokumunca amandla ogongolo lwe-laser futhi zihlangabezana nezidingo ze-sublimation ukuze ukungcola okuvela ebusweni kunyamalale ukuze kufezwe umphumela wokuhlanza. Ngenxa yalokho, ubuso be-substrate bumunca amandla angu-ZERO, noma amandla amancane kakhulu, ukukhanya kwe-fiber laser ngeke kulimaze nhlobo.

Funda kabanzi mayelana nesakhiwo kanye nesimiso se-Handheld Laser Cleaner

Ukusabela Okuthathu Kokuhlanza Nge-Laser

1. Ukususwa kwe-Sublimation

Ukwakheka kwamakhemikhali kwezinto eziyisisekelo kanye nokungcola kuhlukile, futhi nezinga lokumuncwa kwe-laser lihlukile. Isisekelo sesisekelo sibonisa ngaphezu kwama-95% okukhanya kwe-laser ngaphandle komonakalo, kuyilapho ukungcola kumunca iningi lamandla e-laser futhi kufinyelela izinga lokushisa le-sublimation.

Umdwebo Wendlela Yokuhlanza Nge-Laser

2. Ukwanda Kokushisa

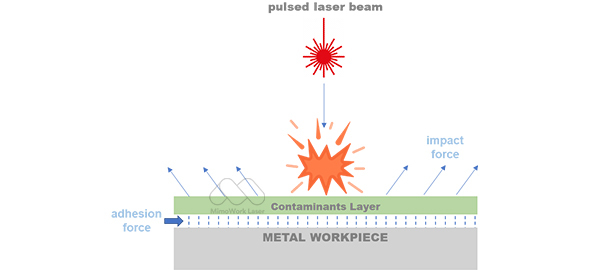

Izinhlayiya ezingcolisayo zimunca amandla okushisa futhi zande ngokushesha kuze kube yilapho kuqhuma khona. Umthelela wokuqhuma unqoba amandla okunamathela (amandla okukhanga phakathi kwezinto ezahlukene), ngakho-ke izinhlayiya ezingcolisayo zisuswa ebusweni bensimbi. Ngenxa yokuthi isikhathi sokukhanya kwe-laser sifushane kakhulu, singakhiqiza ngokushesha ukusheshisa okukhulu kwamandla okuqhuma, okwanele ukunikeza ukusheshisa okwanele kwezinhlayiya ezincane ukuze zisuke ekunamatheleni kwezinto eziyisisekelo.

Umdwebo Wokusebenzisana Kwamandla Okuhlanza Nge-Laser Oshukunyiswayo

3. Ukudlidliza Kwe-Laser Pulse

Ububanzi be-pulse yomsebe we-laser buncane kakhulu, ngakho-ke isenzo esiphindaphindwayo se-pulse sizodala ukudlidliza kwe-ultrasonic ukuze kuhlanzwe umsebenzi, futhi igagasi lokushaqeka lizophula izinhlayiya ezingcolisayo.

Indlela Yokuhlanza Ugongolo Lwe-Laser Olushukunyiswayo

Izinzuzo Zomshini Wokuhlanza I-Fiber Laser

Ngenxa yokuthi ukuhlanza nge-laser akudingi noma yiziphi izinyibilikisi zamakhemikhali noma ezinye izinto ezisetshenziswayo, kunobungani nemvelo, kuphephile ukusebenza, futhi kunezinzuzo eziningi:

✔Impuphu ye-solider ngokuyinhloko imfucuza ngemva kokuhlanzwa, ivolumu encane, futhi kulula ukuyiqoqa nokuyiphinda isetshenziswe

✔Intuthu nomlotha okhiqizwa yi-fiber laser kulula ukuwukhipha ngomshini wokukhipha intuthu, futhi akunzima empilweni yabantu.

✔Ukuhlanza okungenakuthintana, akukho mithombo yezindaba eseleyo, akukho ukungcola kwesibili

✔Ukuhlanza okuqondiwe kuphela (ukugqwala, uwoyela, upende, upende), ngeke kulimaze ubuso be-substrate

✔Ugesi uwukuphela kwezindleko zokusetshenziswa, izindleko zokusebenza eziphansi, kanye nokugcinwa kwawo.

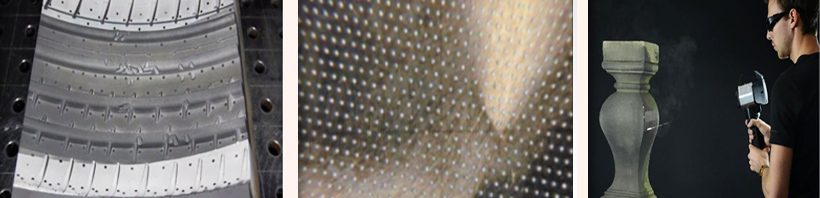

✔Ifanele izindawo okunzima ukuzifinyelela kanye nesakhiwo sezinto eziyinkimbinkimbi

✔Irobhothi yokuhlanza nge-laser ngokuzenzakalelayo iyakhethwa, ithathe indawo yokwenziwa

Ukuze kususwe izinto ezingcolisayo njengokugqwala, isikhunta, upende, amalebula ephepha, ama-polymer, ipulasitiki, noma ezinye izinto ezingaphezulu, izindlela zendabuko - ukuqhuma kwemidiya kanye nokuqopha ngamakhemikhali - zidinga ukuphathwa okukhethekile kanye nokulahlwa kwemidiya futhi kungaba yingozi kakhulu emvelweni nakubasebenza ngezinye izikhathi. Ithebula elingezansi libala umehluko phakathi kokuhlanza nge-laser nezinye izindlela zokuhlanza zezimboni.

| Ukuhlanzwa Nge-Laser | Ukuhlanza Amakhemikhali | Ukupholisha Kwemishini | Ukuhlanza Iqhwa Elomile | Ukuhlanzwa kwe-Ultrasonic | |

| Indlela Yokuhlanza | I-Laser, ukungathintani | Isinyibilikisi samakhemikhali, ukuthintana ngqo | Iphepha elibuhlungu, ukuthintana ngqo | Iqhwa elomile, alithinti | Isepha, ukuthintana ngqo |

| Umonakalo Wezinto Ezibonakalayo | No | Yebo, kodwa akuvamile | Yebo | No | No |

| Ukusebenza Kahle Kokuhlanza | Phezulu | Phansi | Phansi | Okumaphakathi | Okumaphakathi |

| Ukusetshenziswa | Ugesi | Isinyibilikisi Samakhemikhali | Iphepha Eligubhayo/ Isondo Eligubhayo | Iqhwa Elomile | Isicoci Se-solvent |

| Umphumela Wokuhlanza | ukungabi nabala | okuvamile | okuvamile | kuhle kakhulu | kuhle kakhulu |

| Umonakalo Wezemvelo | Okulungele Imvelo | Kungcolisiwe | Kungcolisiwe | Okulungele Imvelo | Okulungele Imvelo |

| Ukusebenza | Kulula futhi kulula ukukufunda | Inqubo eyinkimbinkimbi, kudingeka umqhubi onekhono | kudingeka umqhubi onekhono | Kulula futhi kulula ukukufunda | Kulula futhi kulula ukukufunda |

Ukufuna Indlela Efanele Yokususa Izinto Ezingcolile Ngaphandle Kokonakalisa I-Substrate

▷ Umshini Wokuhlanza Nge-Laser

Imikhuba Yokuhlanza Nge-Laser

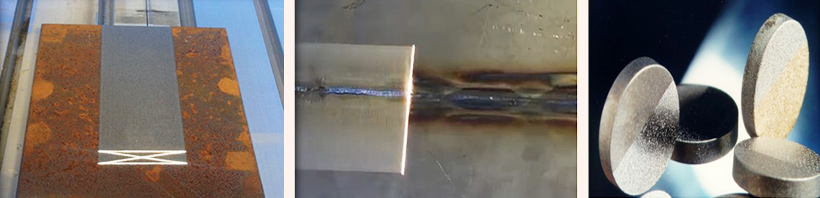

• isikhunta somjovo wokuhlanza nge-laser

• ukurhabaxa kobuso nge-laser

• ukuhlanza nge-laser

• ukususwa kopende nge-laser…

Ukuhlanza Nge-Laser Kusetshenziswa Ngendlela Engokoqobo

Imibuzo Evame Ukubuzwa

Yebo, kuphephile ngokuphelele. Isihluthulelo sisemazingeni ahlukene okumuncwa kwe-laser: izinto eziyisisekelo ziveza amandla e-laser angaphezu kuka-95%, zimunca ukushisa okuncane noma okungenakho nhlobo. Izinto ezingcolisayo (ukugqwala, upende) zimunca amandla amaningi esikhundleni salokho. Isekelwa ukulawulwa kwe-pulse okunembile, inqubo ihlose kuphela izinto ezingafuneki, igwema noma yikuphi ukulimala kwesakhiwo se-substrate noma ikhwalithi yobuso.

Iphatha ukungcola okuningi kwezimboni ngendlela ephumelelayo.

- Ukugqwala, ama-oxide, kanye nokugqwala ezindaweni zensimbi.

- Upende, ukumbozwa, namafilimu amancane avela ezintweni zokusebenza.

- Uwoyela, amafutha, kanye namabala ezinqubweni zokubumba ngomjovo.

- Izinsalela zokushisela kanye nama-burrs amancane ngaphambi/ngemuva kokushisela.

- Akugcini nje ngezinsimbi—futhi kusebenza ezindaweni ezithile ezingezona ezensimbi ukuze kutholakale izinto ezingcolisa ukukhanya.

Kungcono kakhulu emvelweni kunokuhlanza ngamakhemikhali noma ngomshini.

- Azikho izinyibilikisi zamakhemikhali (ezigwema ukungcola kwenhlabathi/amanzi) noma izinto ezisetshenziswayo ezihudulayo (kunciphisa imfucuza).

- Imfucuza ngokuyinhloko iwufulawa omncane oqinile noma intuthu encane, okulula ukuyiqoqa ngemishini yokukhipha intuthu.

- Isebenzisa ugesi kuphela—akudingi ukulahlwa kwemfucuza eyingozi, ihambisana nezindinganiso eziqinile zemvelo zezimboni.

Isikhathi sokuthunyelwe: Julayi-08-2022