Industrial laser cleaning is the process of shooting a laser beam on a solid surface to clean by laser and remove the unwanted substance. Since the price of the fiber laser source has dropped dramatically in the last few years, the laser cleaners—designed to help users clean by laser efficiently—meet more and more broad market demands and applied prospects, such as cleaning injection molding processes, removing thin films or surfaces like oil, and grease, and many more. In this article, we will cover the following topics:

Content List (click to quick locate ⇩)

Laser Cleaning Process.

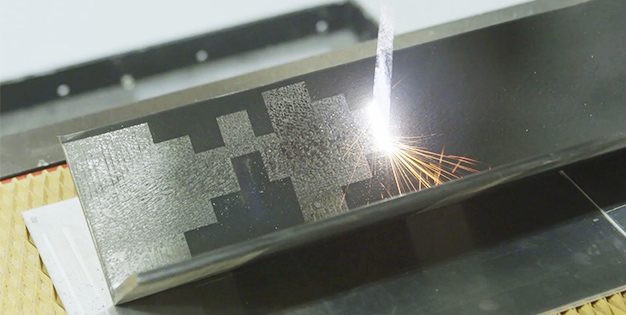

In the 80s, scientists discovered that when illuminating the rusted surface of the metal with high-concentrated laser energy, the irradiated substance undergoes a series of complex physical and chemical reactions such as vibration, melting, sublimation, and combustion. As a result, the contaminants are stripped off from the material's surface. This simple but efficient way of cleaning is laser cleaning, which has gradually replaced the traditional cleaning methods in many fields with many advantages of its own, showing broad prospects for the future.

How do Laser Cleaners Work?

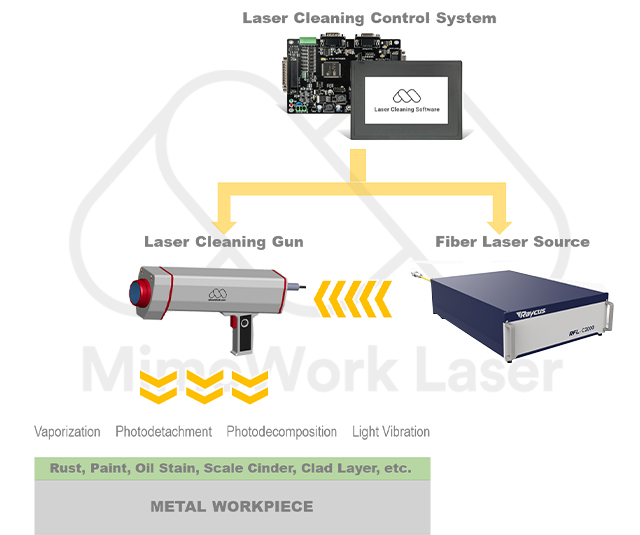

Laser Cleaning Machine

The laser cleaners are made up of four parts: the fiber laser source (continuous or pulse laser), control board, handheld laser gun, and the constant temperature water chiller. The laser cleaning control board acts as the brain of the whole machine and gives the order to the fiber laser generator and the handheld laser gun.

The fiber laser generator produces high-concentrated laser light which is passed through the conduction medium Fiber to the handheld laser gun. The scanning galvanometer, either uniaxial or biaxial, assembled inside the laser gun reflects the light energy to the dirt layer of the workpiece. With a combination of physical and chemical reactions, the rust, paint, greasy dirt, coating layer, and other contamination are removed easily.

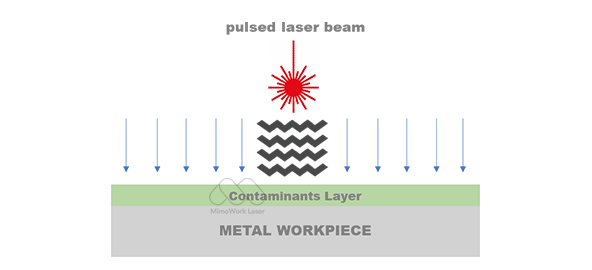

Let’s go into more detail about this process. The complex reactions involved with the use of laser pulse vibration, the thermal expansion of irradiated particles, molecular photodecomposition phase change, or their combined action to overcome the binding force between the dirt and the surface of the workpiece. The target material (the surface layer to be removed) is heated rapidly by absorbing the energy of the laser beam and meets the requirements of sublimation so that the dirt from the surface disappears to achieve the result of cleaning. Because of that, the substrate surface absorbs ZERO energy, or very little energy, the fiber laser light won’t damage it at all.

Learn more about the Structure and Principle of Handheld Laser Cleaner

Three Reactions of Laser Cleaning

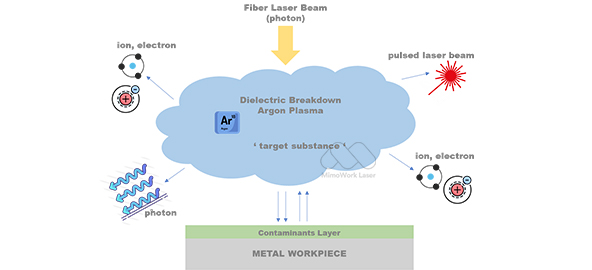

1. Sublimation

The chemical composition of the base material and the contaminant is different, and so is the absorption rate of the laser. The base substrate reflects more than 95% of the laser light without any damage, while the contaminant absorbs the majority of the laser energy and reaches the temperature of sublimation.

Laser Cleaning Mechanism Diagram

2. Thermal Expansion

The pollutant particles absorb the thermal energy and expand rapidly to a point of burst. The impact of the explosion overcomes the force of adhesion (the force of attraction between different substances), and thus the pollutant particles are detached from the surface of the metal. Because the laser irradiation time is very short, it can instantly produce a great acceleration of explosive impact force, enough to provide sufficient acceleration of fine particles to move from the base material adhesion.

Pulsed Laser Cleaning Force Interaction Diagram

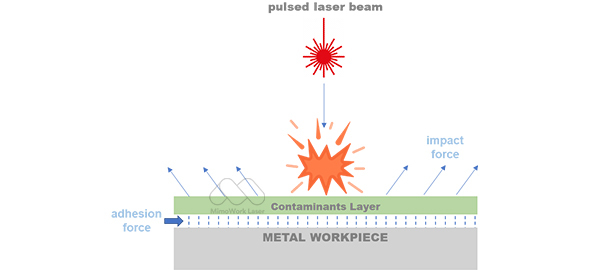

3. Laser Pulse Vibration

The pulse width of the laser beam is relatively narrow, so the repeated action of the pulse will create ultrasonic vibration to clean the workpiece, and the shock wave will shatter the pollutant particles.

Pulsed Laser Beam Cleaning Mechanism

Advantages of Fiber Laser Cleaning Machine

Because laser cleaning does not require any chemical solvents or other consumables, it’s environmentally friendly, safe to operate, and has many advantages:

✔ Solider powder is mainly the waste after cleaning, small volume, and is easy to collect and recycle

✔ Smoke and ash generated by the fiber laser are easy to exhaust by the fume extractor, and not hard to human health

✔ Non-contact cleaning, no residual media, no secondary pollution

✔ Only cleaning the target (rust, oil, paint, coating), won’t damage the substrate surface

✔ Electricity is the only consumption, low running cost, and maintenance cost

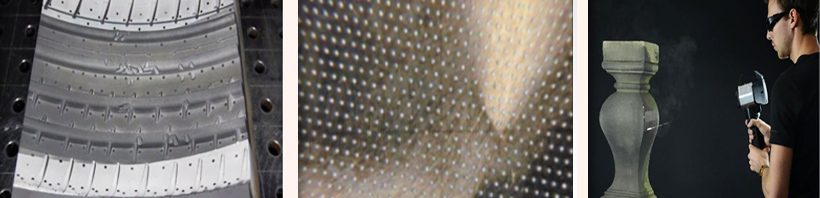

✔ Suitable for hard-to-reach surfaces and complex artifact structure

✔ Automatically laser cleaning robot is optional, replacing artificial

For removing contaminants like rust, mold, paint, paper labels, polymers, plastic, or any other surface material, traditional methods – media blasting and chemical etching – require specialized handling and disposal of the media and can be incredibly hazardous to the environment and operators sometimes. The table below lists the differences between laser cleaning and other industrial cleaning methods

| Laser Cleaning | Chemical Cleaning | Mechanical Polishing | Dry Ice Cleaning | Ultrasonic Cleaning | |

| Cleaning Method | Laser, non-contact | Chemical solvent, direct contact | Abrasive paper, direct contact | Dry ice, non-contact | Detergent, direct-contact |

| Material Damage | No | Yes, but rarely | Yes | No | No |

| Cleaning Efficiency | High | Low | Low | Moderate | Moderate |

| Consumption | Electricity | Chemical Solvent | Abrasive Paper/ Abrasive Wheel | Dry Ice | Solvent Detergent |

| Cleaning Result | spotlessness | regular | regular | excellent | excellent |

| Environmental Damage | Environmental Friendly | Polluted | Polluted | Environmental Friendly | Environmental Friendly |

| Operation | Simple and easy to learn | Complicated procedure, skilled operator required | skilled operator required | Simple and easy to learn | Simple and easy to learn |

Looking for an Ideal Way of Removing Contaminants without Damaging the Substrate

▷ Laser Cleaning Machine

Laser Cleaning Practices

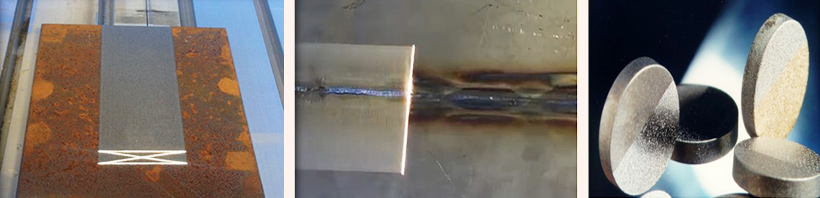

• laser cleaning injection mold

• laser surface roughness

• laser cleaning artifact

• laser paint removal…

Laser Cleaning In Practical Use

FAQS

Yes, it’s completely safe. The key lies in the different laser absorption rates: the base material reflects over 95% of laser energy, absorbing little to no heat. Contaminants (rust, paint) absorb most energy instead. Supported by precise pulse control, the process only targets unwanted substances, avoiding any damage to the substrate’s structure or surface quality.

It handles a wide range of industrial contaminants efficiently.

- Rust, oxides, and corrosion on metal surfaces.

- Paint, coatings, and thin films from workpieces.

- Oil, grease, and stains in injection molding processes.

- Welding residues and small burrs pre/post-welding.

- It’s not limited to metals—also works on certain non-metallic surfaces for light contaminants.

It’s far more eco-friendly than chemical or mechanical cleaning.

- No chemical solvents (avoids soil/water pollution) or abrasive consumables (reduces waste).

- Waste is mainly small solid powder or minimal smoke, which is easy to collect via fume extractors.

- Only uses electricity—no hazardous waste disposal needs, complying with strict industrial environmental standards.

Post time: Jul-08-2022