INTSHAYELELO YOKUSIKA NGELASER

Kukho usetyenziso lwelaser olwahlukeneyo oluqala kwipeni yelaser yesifundo ukuya kwizixhobo zelaser zokubetha okude. Ukusika ngeLaser, njengolwahlulo lwezicelo, kuye kwaphuhliswa kwaye kwagqama kwiindawo zokusika nokukrola. Ngeempawu zelaser ezibalaseleyo, ukusebenza okugqwesileyo kokusika, kunye nokucubungula ngokuzenzekelayo, oomatshini bokusika ngelaser bathatha indawo yezixhobo ezithile zokusika zendabuko. I-CO2 Laser yindlela yokucubungula ethandwa kakhulu. Ububanzi bobude be-10.6μm buhambelana phantse nazo zonke izinto ezingezizo zesinyithi kunye nesinyithi esilaminethiweyo. Ukususela kwilaphu lemihla ngemihla kunye nesikhumba, ukuya kwiplastiki esetyenziswa kwimizi-mveliso, iglasi, kunye nokufakelwa, kunye nezixhobo zobugcisa ezifana nomthi kunye ne-acrylic, umatshini wokusika ngelaser unako ukuzisingatha ezi zinto kwaye ufumane iziphumo ezibalaseleyo zokusika. Ke, nokuba usebenza ngokusika izixhobo kunye nokukrola ukusetyenziswa kwezorhwebo kunye nemizi-mveliso, okanye ufuna ukutyala imali kumatshini omtsha wokusika wokuzonwabisa kunye nomsebenzi wesipho, ukuba nolwazi oluncinci ngomatshini wokusika ngelaser kunye nomatshini wokusika ngelaser kuya kuba luncedo olukhulu kuwe ukwenza isicwangciso.

Ilebhu yoMatshini weLaser yeMimoWork

UBUGCISA

1. Yintoni umatshini wokusika iLaser?

Umatshini wokusika iLaser ngumatshini onamandla wokusika nokukrola olawulwa yinkqubo yeCNC. Umqadi welaser okhawulezayo nonamandla uvela kwityhubhu yelaser apho kwenzeka khona impendulo yomlingo ye-photoelectric. Iityhubhu zelaser zokusika iLaser yeCO2 zahlulwe zibe ziintlobo ezimbini: iityhubhu zelaser zeglasi kunye neetyhubhu zelaser zesinyithi. Umqadi welaser okhutshwayo uya kudluliselwa kwizinto oza kuzisika zizipili ezintathu kunye nelensi enye. Akukho xinzelelo loomatshini, kwaye akukho nxibelelwano phakathi kwentloko yelaser kunye nezinto. Xa umqadi welaser ophethe ubushushu obukhulu udlula kwizinto, uyatshintshwa okanye uncitshiswe. Akukho nto ishiyekileyo ngaphandle kwe-kerf encinci kakhulu kwizinto. Le yinkqubo esisiseko kunye nomgaqo wokusika ilaser yeCO2. Umqadi welaser onamandla uhambelana nenkqubo yeCNC kunye nesakhiwo sothutho esinobuchule, kwaye umatshini wokusika ilaser osisiseko wakhiwe kakuhle ukuze usebenze. Ukuqinisekisa ukusebenza okuzinzileyo, umgangatho wokusika ogqibeleleyo, kunye nemveliso ekhuselekileyo, umatshini wokusika ilaser uxhotyiswe ngenkqubo yokuncedisa umoya, ifeni yokukhupha umoya, isixhobo sokukhupha, kunye nezinye.

2. Isebenza njani iLaser Cutter?

Siyazi ukuba i-laser isebenzisa ubushushu obukhulu ukusika izinto. Ngubani ke othumela imiyalelo yokuqondisa indlela ehambayo kunye nendlela yokusika? Ewe, yinkqubo ye-laser ye-cnc ekrelekrele equka isoftware yokusika i-laser, ibhodi yokulawula, inkqubo yesekethe. Inkqubo yolawulo oluzenzekelayo yenza ukusebenza kube lula kwaye kube lula, nokuba ungumqali okanye uchwephesha. Sidinga nje ukungenisa ifayile yokusika kwaye simisele iiparameter ezifanelekileyo ze-laser ezifana nesantya namandla, kwaye umatshini wokusika i-laser uza kuqala inkqubo elandelayo yokusika ngokwemiyalelo yethu. Yonke inkqubo yokusika kunye nokukrola i-laser iyahambelana kwaye ichanekileyo ngokuphindaphindiweyo. Akumangalisi ukuba i-laser ingumdlali wesantya kunye nomgangatho.

3. Ulwakhiwo lwe-Laser Cutter

Ngokubanzi, umatshini wokusika nge-laser uneenxalenye ezine eziphambili: indawo yokukhupha i-laser, inkqubo yokulawula, inkqubo yokuhamba, kunye nenkqubo yokhuseleko. Icandelo ngalinye lidlala indima ebalulekileyo ekusikeni nasekukroleni ngokuchanekileyo nangokukhawuleza. Ukwazi ezinye izakhiwo kunye neenxalenye zoomatshini bokusika nge-laser, akuncedi nje kuphela ukuba wenze isigqibo esifanelekileyo xa ukhetha kwaye uthenga umatshini, kodwa kukwabonelela ngokuguquguquka ngakumbi kokusebenza kunye nokwandiswa kwemveliso kwixesha elizayo.

Nantsi intshayelelo kwiindawo eziphambili zomatshini wokusika nge-laser:

Umthombo weLaser:

I-CO2 Laser:Isebenzisa umxube wegesi owenziwe ikakhulu yi-carbon dioxide, nto leyo eyenza ukuba ilungele ukusika izinto ezingezizo ezesinyithi ezifana nomthi, i-acrylic, ilaphu, kunye neentlobo ezithile zamatye. Isebenza kubude obumalunga ne-10.6 micrometers.

I-Fiber Laser:Isebenzisa itekhnoloji yelaser yesimo esiqinileyo enemicu ye-optical exutywe nezinto ezinqabileyo zomhlaba ezifana ne-ytterbium. Isebenza kakuhle kakhulu ekusikeni iintsimbi ezifana nentsimbi, i-aluminium, kunye nobhedu, isebenza kubude obumalunga ne-1.06 micrometers.

I-Nd:YAG Ileza:Isebenzisa ikristale ye-garnet ye-aluminium ye-yttrium ene-neodymium. Iyakwazi ukuguquguquka kwaye ingasika zombini iintsimbi kunye nezinye ezingezizo iintsimbi, nangona ingaqhelekanga kune-CO2 kunye ne-fiber lasers zokusika.

Ityhubhu yeLaser:

Igcina i-laser medium (igesi ye-CO2, kwimeko yee-laser ze-CO2) kwaye ivelisa umqadi we-laser ngokusebenzisa umbane ovuthuzayo. Ubude kunye namandla etyhubhu ye-laser amisela amandla okusika kunye nobukhulu bezinto ezinokusikwa. Kukho iintlobo ezimbini zetyhubhu ye-laser: ityhubhu ye-laser yeglasi kunye netyhubhu ye-laser yesinyithi. Iingenelo zeetyhubhu ze-laser zeglasi zinokulinganisela kwaye zinokuphatha ukusika kwezinto ezilula ngaphakathi koluhlu oluthile lokuchaneka. Iingenelo zeetyhubhu ze-laser zesinyithi bubomi benkonzo ende kunye nokukwazi ukuvelisa ukuchaneka okuphezulu kwe-laser.

Inkqubo yokubona:

Izipili:Zibekwe ngendlela efanelekileyo ukuze ziqondise umqadi welaser ukusuka kwityhubhu yelaser ukuya entloko yokusika. Kufuneka zilungelelaniswe ngokuchanekileyo ukuqinisekisa ukuhanjiswa komqadi ngokuchanekileyo.

Iilensi:Gxininisa umqadi welaser ukuya kwinqanaba elincinci, uphucule ukuchaneka kokusika. Ubude be-focal yelensi buchaphazela ukujolisa komqadi kunye nobunzulu bokusika.

Intloko yokusika iLaser:

Ilensi yokugxila:Iguqula umqadi welaser ube yindawo encinci ukuze unqunyulwe ngokuchanekileyo.

Impumlo:Ii-Directs zinceda iigesi (ezifana neoksijini okanye initrogen) kwindawo yokusika ukuphucula ukusebenza kakuhle kokusika, ukuphucula umgangatho wokusika, kunye nokuthintela ukuqokelelana kwenkunkuma.

Inzwa yokuphakama:Igcina umgama olinganayo phakathi kwentloko yokusika kunye nezinto ezisetyenzisiweyo, iqinisekisa umgangatho ofanayo wokusika.

Umlawuli we-CNC:

Inkqubo yoLawulo lweeNani zeKhompyutha (CNC): Ilawula imisebenzi yomatshini, kuquka intshukumo, amandla elaser, kunye nesantya sokusika. Itolika ifayile yoyilo (ngesiqhelo kwi-DXF okanye kwiifomathi ezifanayo) kwaye iyiguqulele kwiintshukumo ezichanekileyo kunye nezenzo zelaser.

Itheyibhile Yokusebenza:

Itafile yeShuttle:Itafile yeshuttle, ekwabizwa ngokuba yi-pallet changer, yenziwe ngendlela yoyilo lokudlulisa ukuze ithuthwe ngeendlela ezimbini. Ukuze kube lula ukulayishwa nokukhutshwa kwezinto ezinokunciphisa okanye ziphelise ixesha lokungasebenzi kwaye zihlangabezane nokusikwa kwezinto ezithile, siyile ubungakanani obahlukeneyo ukuze bufanele ubungakanani bonke boomatshini bokusika nge-laser beMimoWork.

Ibhedi yeLaser yobusi:Ibonelela ngomphezulu othe tyaba nozinzileyo onendawo encinci yokudibana, inciphisa ukubonakaliswa komva kwaye ivumela ukunqunyulwa okucocekileyo. Ibhedi yehoneycomb yelaser ivumela umoya olula wobushushu, uthuli, kunye nomsi ngexesha lenkqubo yokusika ilaser.

Itheyibhile yeMicu yeMese:Eyona nto iphambili kukusika izinto ezijiyileyo apho ungathanda ukuphepha ukujija nge-laser. Iibhari ezithe nkqo zikwavumela ukuhamba kakuhle komoya xa usika. Ii-lamellas zingabekwa zodwa, ngenxa yoko, itafile ye-laser ingalungiswa ngokwesicelo ngasinye.

Itheyibhile yoThutho:Itafile yokuhambisa impahla yenziwe ngeiwebhu yentsimbi engagqwaliyoefanelekileyoizinto ezibhityileyo neziguquguqukayo ezifanaifilimu,ilaphukwayeulusu.Ngenkqubo yokuhambisa, ukusika nge-laser okungapheliyo kuya kuba nokwenzeka. Ukusebenza kakuhle kweenkqubo ze-laser zeMimoWork kunokwandiswa ngakumbi.

Itheyibhile yeGridi yokuSika i-Acrylic:Kubandakanya itafile yokusika nge-laser enegridi, igridi ekhethekileyo yokukrola nge-laser ithintela ukuphinda kubonakale ngasemva. Ngoko ke ilungele ukusika ii-acrylics, ii-laminates, okanye iifilimu zeplastiki ezineendawo ezincinci kune-100 mm, njengoko ezi zihlala zikwindawo ethe tyaba emva kokunqunyulwa.

Itheyibhile Yokusebenza Ngephini:Iqulathe iiphini ezininzi ezihlengahlengiswayo ezinokucwangciswa ngeendlela ezahlukeneyo ukuxhasa izinto ezisikiweyo. Olu yilo lunciphisa unxibelelwano phakathi kwezinto kunye nomphezulu womsebenzi, nto leyo ebonelela ngeenzuzo ezininzi zokusika nge-laser kunye nokusetyenziswa kwe-engraving.

Inkqubo yokuShukuma:

IiStepper Motors okanye iiServo Motors:Qhuba iintshukumo ze-X, Y, kwaye ngamanye amaxesha i-Z-axis zentloko yokusika. Iimoto zeServo ngokubanzi zichanekile kwaye zikhawuleza kuneemoto ze-stepper.

Izikhokelo eziLula kunye neeRails:Qinisekisa ukuba intloko yokusika ishukuma kakuhle nangokuchanekileyo. Zibalulekile ekugcineni ukuchaneka nokungaguquguquki kokusika ixesha elide.

Inkqubo yokupholisa:

Isitshizi samanzi: Igcina ityhubhu yelaser kunye nezinye izinto zikwiqondo lobushushu elifanelekileyo ukuthintela ubushushu obugqithisileyo kunye nokugcina ukusebenza okulinganayo.

Uncedo lomoya:Ivuthela umoya nge-nozzle ukuze isuse ubumdaka, inciphise iindawo ezichaphazeleka bubushushu, kwaye iphucule umgangatho wokusika.

Inkqubo yokukhupha umoya:

Susa umsi, umsi, kunye nezinto eziphuma ngexesha lenkqubo yokusika, ukuqinisekisa indawo yokusebenza ecocekileyo nekhuselekileyo. Umoya ofanelekileyo ubalulekile ekugcineni umgangatho womoya kunye nokukhusela umqhubi kunye nomatshini.

Iphaneli yokulawula:

Ibonelela ngojongano lwabasebenzisi lokufaka useto, ukujonga imeko yomatshini, nokulawula inkqubo yokusika. Ingabandakanya umboniso wesikrini sokuchukumisa, iqhosha lokumisa ngexesha likaxakeka, kunye neendlela zokulawula ngesandla zokulungisa izinto ezincinci.

Iimpawu zoKhuseleko:

Isixhobo seZigqubo:Khusela abaqhubi kwi-laser kunye nenkunkuma enokubakho. Ii-enclosures zihlala zitshixiwe ukuze zivale i-laser ukuba ivuliwe ngexesha lokusebenza.

Iqhosha Lokumisa Ngengxakeko:Ivumela ukucima umatshini ngoko nangoko xa kukho imeko engxamisekileyo, iqinisekisa ukhuseleko lomqhubi.

Izinzwa zoKhuseleko lweLaser:Fumana naziphi na izinto ezingaqhelekanga okanye iimeko ezingakhuselekanga, nto leyo ebangela ukuvalwa ngokuzenzekelayo okanye izilumkiso.

Isoftware:

Isoftware Yokusika NgeLaser: I-MimoCUT, isoftware yokusika nge-laser, yenzelwe ukwenza umsebenzi wakho wokusika ube lula. Ukulayisha nje iifayile zakho zevektha ze-laser cut. I-MimoCUT iya kuguqulela imigca, amanqaku, ii-curves, kunye neemilo ezichaziweyo kulwimi lwenkqubo olunokuqatshelwa yisoftware yokusika nge-laser, kwaye ikhokele umatshini we-laser ukuba uyisebenzise.

Isoftware ye-Auto-Nest:I-MimoNEST, isoftware yokusika iindlwane nge-laser inceda abenzi bezixhobo ukunciphisa iindleko zezinto kwaye iphucula izinga lokusetyenziswa kwezinto ngokusebenzisa ii-algorithms eziphambili ezihlalutya umahluko weendawo. Ngamazwi alula, inokubeka iifayile zokusika nge-laser kwizinto ngokugqibeleleyo. Isoftware yethu yokusika iindlwane nge-laser inokusetyenziswa ekusikeni uluhlu olubanzi lwezinto njengezicwangciso ezifanelekileyo.

Isoftware Yokuqaphela Iikhamera:I-MimoWork iyaphuhliswa Inkqubo yokuBeka iLaser yekhamera yeCCD enokuqaphela nokufumana iindawo zeempawu ukukunceda wonge ixesha kwaye wonyuse ukuchaneka kokusika nge-laser ngaxeshanye. Ikhamera ye-CCD ixhotyiswe ecaleni kwentloko ye-laser ukukhangela umsebenzi usebenzisa iimpawu zokubhalisa ekuqaleni kwenkqubo yokusika. Ngale ndlela, iimpawu eziprintiweyo, ezilukiweyo nezithungiweyo kunye nezinye iikhonteyina eziphezulu zinokuskenwa ngokubonakalayo ukuze ikhamera yokusika nge-laser ikwazi ukwazi apho indawo yokwenyani kunye nobukhulu beziqwenga zomsebenzi zikhoyo, ukuze kufezekiswe uyilo oluchanekileyo lokusika nge-laser.

Isoftware yokuProjektha:Nge Isoftware yeMimo Projection, umzobo kunye nendawo yezinto eziza kusikwa ziya kubonakala etafileni yokusebenza, nto leyo enceda ekulinganiseni indawo echanekileyo yomgangatho ophezulu wokusika nge-laser. NgokwesiqheloIzihlangu okanye Izihlanguukusika nge-laser kusebenzisa isixhobo sokubonisa. Ezifana Isikhumba sokwenyani izihlangu, ulusu lwe-pu izihlangu, ii-uppers zokuluka, iiteki.

Isoftware yomzekelo:Ngokusebenzisa ikhamera ye-HD okanye iskena sedijithali, I-MimoPROTOTYPE iyaziqonda ngokuzenzekelayo ii-designs kunye needati zokuthunga zesixhobo ngasinye kwaye ivelise iifayile zoyilo onokuzifaka kwisoftware yakho yeCAD ngokuthe ngqo. Xa kuthelekiswa ne-manual manual measurement point by point, ukusebenza kakuhle kwesoftware yeprototype kuphezulu kaninzi. Udinga kuphela ukubeka iisampulu zokusika etafileni yokusebenza.

Iigesi zoNcedo:

Ioksijini:Iphucula isantya sokusika kunye nomgangatho weentsimbi ngokuncedisa ukusabela kwe-exothermic, okongeza ubushushu kwinkqubo yokusika.

I-nitrogen:Isetyenziselwa ukusika izinto ezingezizo iintsimbi kunye nezinye iintsimbi ukuze kufumaneke ukusikwa okucocekileyo ngaphandle kokufakwa kweoksijini.

Umoya ocinezelweyo:Isetyenziselwa ukusika izinto ezingezizo iintsimbi ukuze zivuthuze izinto ezinyibilikisiweyo kwaye zithintele ukutsha.

Ezi zinto zisebenza ngokubambisana ukuqinisekisa imisebenzi yokusika nge-laser echanekileyo, esebenzayo, nekhuselekileyo kuzo zonke izixhobo ezahlukeneyo, nto leyo eyenza oomatshini bokusika nge-laser babe zizixhobo ezisebenzisekayo kwimveliso nakwimveliso yanamhlanje.

Imisebenzi emininzi kunye nokuguquguquka kwesikhi se-laser sekhamera senza ukuba ilebheli elukiweyo, isitikha, kunye nefilimu enamathelayo inqunyulwe kwinqanaba eliphezulu ngokusebenza kakuhle nangokuchaneka okuphezulu. Iipateni zokuprinta kunye nokuhombisa kwi-patch kunye nelebheli elukiweyo kufuneka zinqunyulwe ngokuchanekileyo...

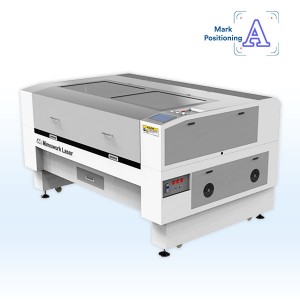

Ukuze kuhlangatyezwane neemfuno zamashishini amancinci, kunye noyilo olucwangcisiweyo, iMimoWork iyile isixhobo sokusika i-laser esincinci esinobukhulu bedesktop obuyi-600mm * 400mm. Isixhobo sokusika i-laser sekhamera sifanelekile ekusikeni ipetshi, ukuhombisa, isitikha, ilebheli, kunye nezixhobo ezisetyenziswa kwiimpahla kunye nezixhobo...

I-contour laser cutter 90, ekwabizwa ngokuba yi-CCD laser cutter iza nobukhulu bomatshini obuyi-900mm * 600mm kunye noyilo lwe-laser oluvaliweyo ngokupheleleyo ukuqinisekisa ukhuseleko olugqibeleleyo, ngakumbi kwabaqalayo. Nge-CCD Camera efakwe ecaleni kwentloko ye-laser, nayiphi na ipatheni kunye nemilo...

Yenzelwe ngokukodwa iShishini leeMpawu kunye neFenitshala, Sebenzisa amandla eTekhnoloji yeKhamera yeCCD ePhambili ukuze usike kakuhle i-Acrylic eprintiweyo enePateni. Nge-Ball Screw Transmission kunye neenketho zeMoto yeServo eNgcono kakhulu, Zintywilisele kwi-Unmatched Precision kunye...

Fumana amava oMdibaniso oPhezulu woBugcisa kunye neTekhnoloji ngeMimowork's Printed Wood Laser Cutter. Vula ihlabathi lamathuba njengoko usika kwaye ukrola ngaphandle komthungo iinkuni kunye neemveliso zeenkuni eziprintiweyo. Yenzelwe iShishini leeMpawu kunye neFenitshala, iLaser Cutter yethu isebenzisa i-Advanced CCD...

Ifakwe kwiKhamera yeHD yanamhlanje ebekwe phezulu, ibona ngokulula imilo kwaye idlulisele idatha yeepateni ngqo kumatshini wokusika ilaphu. Valelisa kwiindlela zokusika ezintsonkothileyo, njengoko obu buchwephesha bubonelela ngesisombululo esilula nesichanekileyo selayisi kunye...

Ukwazisa uMatshini weMidlalo weLaser Cut (160L) – isisombululo esigqibeleleyo sokusika idayi. Ngekhamera yayo entsha yeHD, lo matshini unokubona ngokuchanekileyo kwaye udlulisele idatha yepateni ngqo kumatshini wokusika ipateni yelaphu. Iphakheji yethu yesoftware inikezela ngeendlela ezahlukeneyo.

Ukwazisa i-Sublimation Polyester Laser Cutter (180L) etshintsha umdlalo – isisombululo esigqibeleleyo sokusika amalaphu e-sublimation ngokuchanekileyo okungenakuthelekiswa nanto. Ngobungakanani betafile yokusebenza obukhulu obuyi-1800mm*1300mm, le cutter yenzelwe ngokukodwa ukucubungula i-polyester eprintiweyo...

Ngena kwihlabathi elikhuselekileyo, elicocekileyo, nelichanekileyo lokusika ilaphu le-sublimation nge-Laser Cut Sportswear Machine (Efakwe ngokupheleleyo). Isakhiwo sayo esivaliweyo sinika iingenelo ezintathu: ukhuseleko oluphuculweyo lwabaqhubi, ulawulo oluphezulu lothuli, kunye nokungcono...

Ukuze kuhlangatyezwane neemfuno zokusika zelaphu elikhulu nelibanzi le-roll ngelaphu, iMimoWork iyile i-ultra-wide format sublimation laser cutter ene-CCD Camera ukunceda ukusika i-contour kwilaphu eliprintiweyo njengeebhanile, iiflegi ze-teardrop, imiqondiso, umboniso, umboniso, njl. Indawo yokusebenza eyi-3200mm * 1400mm...

I-Contour Laser Cutter 160 ixhotyiswe ngekhamera ye-CCD efanelekileyo yokucubungula oonobumba abajijekileyo, amanani, iileyibhile, izixhobo zempahla, amalaphu asekhaya. Umatshini wokusika nge-laser yekhamera usebenzisa isoftware yekhamera ukuze aqonde iindawo ezibonakalayo aze enze ukusika iipateni ngokuchanekileyo...

▷ Umatshini wokusika i-laser osikiweyo (owenzelwe wena)

Ubungakanani bomatshini oqinileyo bugcina indawo kakhulu kwaye bunokwamkela izinto ezidlula ububanzi bokusika ngoyilo lokungena oluneendlela ezimbini. I-Mimowork's Flatbed Laser Engraver 100 yenzelwe ukukrola nokusika izinto eziqinileyo kunye nezinto eziguquguqukayo, ezifana nomthi, i-acrylic, iphepha, amalaphu...

Umkroli weLaser yoMthi onokwenziwa ngokwezifiso zakho kunye nohlahlo-lwabiwo mali lwakho. I-MimoWork's Flatbed Laser Cutter 130 yenzelwe ukukrola nokusika imithi (iplywood, iMDF), ingasetyenziselwa ne-acrylic kunye nezinye izinto. Umkroli welaser oguquguqukayo unceda ekufezekiseni umthi olungiselelwe wena...

Umatshini wokukrola ngeLaser ye-Acrylic onokwenziwa ngokwezifiso zakho kunye nohlahlo-lwabiwo mali lwakho. I-Mimowork's Flatbed Laser Cutter 130 yenzelwe ukukrola nokusika i-acrylic (plexiglass/PMMA), ingasetyenziselwa nomthi kunye nezinye izinto. Ukukrola ngeLaser eguquguqukayo kunceda...

Ilungele ukusika amaphepha amakhulu kunye namakhulu eenkuni ukuze kuhlangatyezwane neentengiso ezahlukeneyo kunye nezicelo zemizi-mveliso. Itafile yokusika i-laser ye-1300mm * 2500mm yenzelwe ukufikelela kwiindlela ezine. Iphawulwa ngesantya esiphezulu, umatshini wethu wokusika i-laser yeenkuni ye-CO2 unokufikelela kwisantya sokusika se-36,000mm nge...

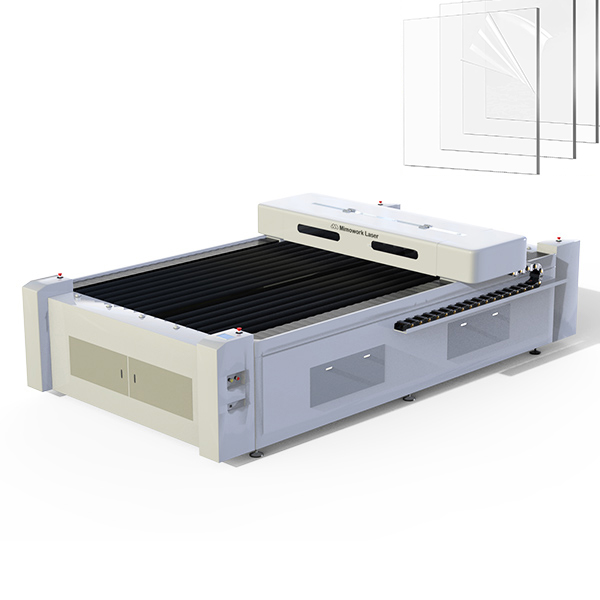

Ilungele ukusika nge-laser enkulu kunye namaphepha e-acrylic atyebileyo ukuze kuhlangatyezwane nezicelo ezahlukeneyo zentengiso kunye nezoshishino. Itafile yokusika nge-laser eyi-1300mm * 2500mm yenzelwe ukufikelela kwiindlela ezine. Amaphepha e-acrylic okusika nge-laser asetyenziswa kakhulu kushishino lokukhanyisa kunye norhwebo, kwicandelo lokwakha...

Umatshini we-laser omncinci nomncinci uthatha indawo encinci kwaye kulula ukuwusebenzisa. Ukusika nokukrola nge-laser okuguquguqukayo kuhambelana nezi mfuno zemarike ezenzelwe wena, ezibalaseleyo kwicandelo lemisebenzi yezandla yamaphepha. Ukusika amaphepha okuntsonkotha kumakhadi esimemo, amakhadi okubulisa, iincwadana, i-scrapbooking, kunye namakhadi eshishini...

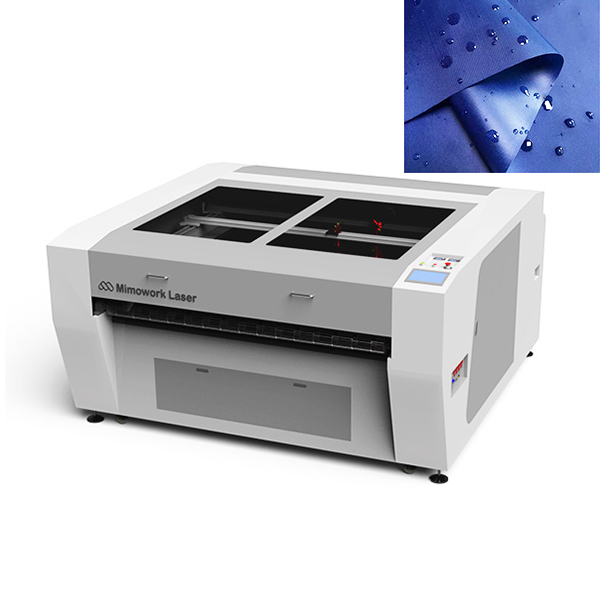

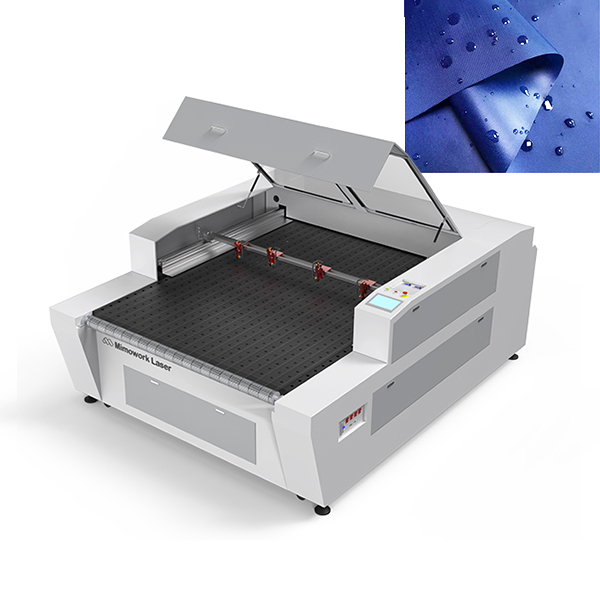

Ngokuhambelana nobukhulu obuqhelekileyo bempahla kunye neempahla, umatshini wokusika ilaphu nge-laser unetafile yokusebenza eyi-1600mm * 1000mm. Ilaphu elithambileyo eligoqekayo lifanelekile kakhulu ekusikweni nge-laser. Ngaphandle koko, isikhumba, ifilimu, i-felt, i-denim kunye nezinye iziqwenga zonke zinokusikwa nge-laser ngenxa yetafile yokusebenza ekhethiweyo...

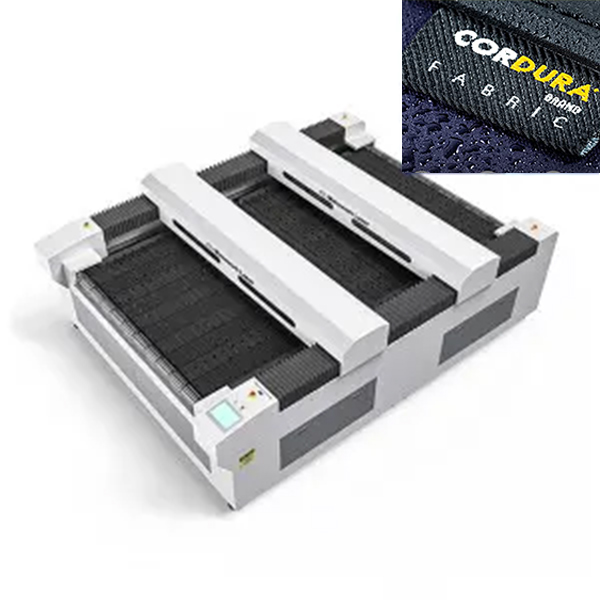

Ngokusekelwe kumandla aphezulu kunye noxinano lweCordura, ukusika nge-laser yindlela esebenza kakuhle ngakumbi yokucubungula ngakumbi imveliso ye-PPE kwimizi-mveliso kunye nezixhobo zomkhosi. Umatshini wokusika nge-laser ngelaphu lemizi-mveliso unendawo enkulu yokusebenza ukuhlangabezana nefomathi enkulu yokusika efana ne-Cordura...

Ukuze kuhlangatyezwane neemfuno ezininzi zokusika zelaphu ngobukhulu obahlukeneyo, iMimoWork yandisa umatshini wokusika ngelaser ukuya kwi-1800mm * 1000mm. Xa idibene netafile yokuhambisa, ilaphu eligoqekayo kunye nesikhumba zinokuvunyelwa ukuhambisa kunye nokusika ngelaser kwimfashini kunye namalaphu ngaphandle kokuphazamiseka. Ukongeza, iintloko ze-laser ezininzi...

Umatshini wokusika iLaser enkulu oyiFomathi yeLaser wenzelwe amalaphu amade kakhulu kunye namalaphu. Ngomgca wetafile yokusebenza oyimitha ezili-10 ubude kunye nemitha eli-1.5 ububanzi, umsiki welaser omkhulu ufanelekile kwiishethi ezininzi zelaphu kunye neeroli ezifana netente, iparashuti, i-kitesurfing, ikhaphethi yeenqwelo moya, i-pelmet yentengiso kunye neempawu, ilaphu lokuhamba ngesikhephe kunye nokunye...

Umatshini wokusika i-laser ye-CO2 uxhotyiswe ngenkqubo yeprojektha enomsebenzi ochanekileyo wokubeka indawo. Umboniso wesixhobo somsebenzi oza kusikwa okanye oza kuqoshwa unceda ukuba ubeke izinto kwindawo efanelekileyo, nto leyo evumela ukuba ukusika emva kwe-laser kunye nokuqoshwa kwe-laser kuhambe kakuhle nangokuchaneka okuphezulu...

Umatshini weGalvo Laser (Sika & Ukrole & Ugqobhoze)

I-MimoWork Galvo Laser Marker ngumatshini osetyenziselwa iinjongo ezininzi. Ukukrola nge-laser ephepheni, iphepha lokusika nge-laser elenziwe ngokwezifiso kunye nokugqobhoza iphepha konke kunokugqityezelwa ngomatshini we-galvo laser. Umqadi we-laser we-Galvo onobunono obuphezulu, ukuguquguquka, kunye nesantya sombane kudala izinto ezenziwe ngokwezifiso...

Umqadi welaser obhabhayo ukusuka kwi-engile yelensi eguquguqukayo unokufezekiswa ngokukhawuleza ngaphakathi kwesikali esichaziweyo. Ungalungisa ukuphakama kwentloko yelaser ukuze ilingane nobukhulu bezinto ezicutshungulwayo. Ityhubhu yelaser yesinyithi ye-RF inika uphawu oluchanekileyo oluphezulu olune-laser spot encinci ukuya kwi-0.15mm, efanelekileyo kwi-laser yepateni entsonkothileyo ekroliweyo kwisikhumba...

Umatshini welaser weFly-Galvo uxhotyiswe kuphela ngetyhubhu yelaser yeCO2 kodwa unokubonelela ngokugqobhoza kwelaser yelaphu kunye nokusika kwelaser kwiimpahla kunye namalaphu emizi-mveliso. Ngetafile yokusebenza ye-1600mm * 1000mm, umatshini welaser yelaphu egqobhoziweyo unokuthwala uninzi lwamalaphu eefomathi ezahlukeneyo, ufezekise imingxunya yokusika yelaser ehambelanayo...

I-GALVO Laser Engraver 80 enoyilo oluvaliweyo ngokupheleleyo ngokuqinisekileyo lukhetho lwakho olufanelekileyo lokukrola kunye nokumakisha nge-laser yemizi-mveliso. Ngenxa yombono wayo ophezulu we-GALVO ongu-800mm * 800mm, ifanelekile ekukroleni, ekumakisheni, ekusikeni, nasekugqobhozeni nge-laser kwisikhumba, kwikhadi lephepha, kwi-vinyl yokudlulisa ubushushu, okanye nakweyiphi na enye into enkulu...

Umkroli welaser onefomathi enkulu yiR&D yezinto ezinkulu zokukrola ngelaser kunye nokumakisha ngelaser. Ngenkqubo yokuhambisa, umkroli welaser wegalvo unokukrola kwaye uphawule kwilaphu eligoqekayo (iileyiphu). Ungayithatha njengomatshini wokukrola ngelaser yelaphu, umatshini wokukrola ngelaser yekhaphethi, umkroli welaser wedenim...

Uhlahlo lwabiwo-mali

Nokuba ngoobani na oomatshini okhetha ukubathenga, iindleko eziquka ixabiso lomatshini, iindleko zokuthumela, ukufakela, kunye neendleko zokulungisa emva kokulungiswa zihlala ziyingqwalasela yakho yokuqala. Kwinqanaba lokuthenga kwasekuqaleni, unokumisela iimfuno zokusika ezibaluleke kakhulu zemveliso yakho ngaphakathi komda othile webhajethi. Fumana ulungelelwaniso lwelaser kunye neendlela zomatshini welaser ezihambelana nemisebenzi kunye nohlahlo-lwabiwo mali. Ngaphandle koko, kufuneka uqwalasele iindleko zokufakela kunye nokusebenza, njengokuthi kukho iindleko zoqeqesho olongezelelweyo, nokuba uqesha abasebenzi, njl. Oko kukunceda ukuba ukhethe umthengisi ofanelekileyo womatshini welaser kunye neentlobo zoomatshini ngaphakathi kohlahlo-lwabiwo mali.

Amaxabiso oomatshini bokusika nge-laser ayahluka ngokweentlobo zoomatshini, uqwalaselo, kunye neendlela onokukhetha kuzo. Sixelele iimfuno zakho kunye nohlahlo-lwabiwo mali, kwaye ingcali yethu ye-laser iya kukucebisa umatshini wokusika nge-laser onokukhetha kuwo.⇨I-MimoWork Laser

Isixhobo seLaser

Xa utyala imali kumatshini wokusika nge-laser, kufuneka wazi ukuba ngowuphi umthombo we-laser onokukwazi ukusika izinto zakho uze ufikelele kwisiphumo esilindelekileyo sokusika. Kukho imithombo emibini eqhelekileyo ye-laser:i-fiber laser kunye ne-CO2 laser. I-laser yefayibha isebenza kakuhle ekusikeni nasekuphawuleni izinto zesinyithi kunye ne-alloy. I-laser ye-CO2 igxile ekusikeni nasekukroleni izinto ezingezizo ezesinyithi. Ngenxa yokusetyenziswa kakhulu kwee-laser ze-CO2 ukusuka kwinqanaba loshishino ukuya kwinqanaba lokusetyenziswa kwemihla ngemihla ekhaya, iyakwazi kwaye kulula ukuyisebenzisa. Xoxa ngezixhobo zakho neengcali zethu ze-laser, uze emva koko umisele umthombo we-laser ofanelekileyo.

Uqwalaselo loomatshini

Emva kokufumanisa umthombo we-laser, kufuneka uxoxe ngeemfuno zakho ezithile zezinto zokusika ezifana nesantya sokusika, ubungakanani bemveliso, ukuchaneka kokusika, kunye neempawu zezinto kunye neengcali zethu ze-laser. Oko kugqiba ukuba zeziphi iindlela zokumisela i-laser kunye neendlela ezifanelekileyo kwaye zinokufikelela kwisiphumo esifanelekileyo sokusika. Umzekelo, ukuba unemfuno ephezulu yemveliso yemihla ngemihla, isantya sokusika kunye nokusebenza kakuhle kuya kuba yinto yokuqala oza kuyiqwalasela. Iintloko ezininzi ze-laser, iinkqubo zokutyisa ngokuzenzekelayo kunye nezokuhambisa, kunye nesoftware ethile yokwenza i-auto-nesting inokuphucula ukusebenza kwakho kwemveliso. Ukuba unomdla kakhulu ekuchanekeni kokusika, mhlawumbi i-servo motor kunye netyhubhu ye-laser yesinyithi zifanelekile kuwe.

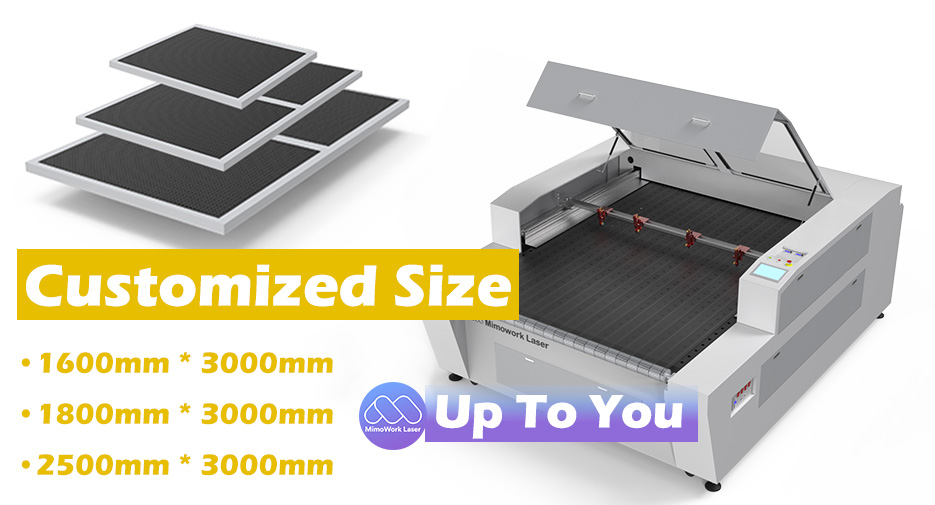

Indawo Yokusebenza

Indawo yokusebenza yinto ebalulekileyo ekukhetheni oomatshini. Ngokwesiqhelo, ababoneleli boomatshini be-laser babuza ngolwazi lwakho lwezinto eziphathekayo, ingakumbi ubungakanani bezinto eziphathekayo, ubukhulu, kunye nobukhulu bepateni. Oko kumisela ifomathi yetafile yokusebenza. Kwaye ingcali ye-laser iya kuhlalutya ubungakanani bepateni yakho kunye noyilo lwemilo ngokuxoxa nawe, ukuze kufunyanwe indlela efanelekileyo yokondla ehambelana netafile yokusebenza. Sinobukhulu obuqhelekileyo bokusebenza bomatshini wokusika i-laser, onokuhlangabezana neemfuno zabathengi abaninzi, kodwa ukuba unezinto ezikhethekileyo kunye neemfuno zokusika, nceda usazise, ingcali yethu ye-laser inobuchule kwaye inamava okusingatha ingxaki yakho.

Ubugcisa

Umatshini wakho

| Ubungakanani bokusebenza komatshini (W * L) |

| •600mm * 400mm |

| •1000mm * 600mm |

| •1300mm * 900mm |

| •1300mm * 2500mm |

| •1600mm * 1000mm |

| •1600mm * 1200mm |

| •1600mm * 3000mm |

| •1600mm * 10000mm |

| •1800mm * 1400mm |

| •2500mm * 3000mm |

| •3200mm * 1400mm |

Ukuba Uneemfuno Ezikhethekileyo Zobungakanani Bomatshini, Thetha Nathi!

Umenzi woomatshini

Kulungile, sele unolwazi lwakho lwezinto eziphathekayo, iimfuno zokusika, kunye neentlobo zoomatshini abasisiseko, inyathelo elilandelayo olifunayo lokukhangela umenzi womatshini wokusika i-laser othembekileyo. Ungakhangela kuGoogle, nakwiYouTube, okanye ubuze abahlobo bakho okanye amaqabane akho, nokuba yeyiphi na indlela, ukuthembeka kunye nobunyani bababoneleli bomatshini kusoloko kubaluleke kakhulu. Zama ukubathumelela i-imeyile, okanye uthethe nengcali yabo ye-laser kwiWhatsApp, ukuze ufunde ngakumbi malunga nokuveliswa komatshini, apho umzi-mveliso ukhoyo, indlela yokuqeqesha kunye nokukhokela emva kokufumana umatshini, kunye nezinye ezinjalo. Abanye abathengi bakhe baodola umatshini kwiifektri ezincinci okanye kumaqonga eqela lesithathu ngenxa yexabiso eliphantsi, nangona kunjalo, xa umatshini uneengxaki ezithile, awufumani naluphi na uncedo kunye nenkxaso, okuya kulibazisa imveliso yakho kunye nokuchitha ixesha.

I-MimoWork Laser ithi: Sisoloko sibeka phambili iimfuno zomthengi kunye namava okusebenzisa. Oko ufumanayo akupheleli nje ekubeni ngumatshini we-laser omhle noqinileyo, kodwa kunye neseti yenkonzo epheleleyo kunye nenkxaso ukusuka ekufakweni, uqeqesho ukuya ekusebenzeni.

① Fumana umenzi othembekileyo

Uphendlo lukaGoogle kunye nolweYouTube, okanye undwendwele ireferensi yasekuhlaleni

② Jonga iwebhusayithi okanye iYouTube yayo

Jonga iintlobo zoomatshini kunye nolwazi lwenkampani

③ Nxibelelana neNgcali yeLaser

Thumela i-imeyile okanye uncokole nge-WhatsApp

⑥ Beka i-odolo

Misela ixesha lokuhlawula

⑤ Chonga ezoThutho

ukuthunyelwa okanye ukuthuthwa ngenqwelomoya

④ Intlanganiso ekwi-intanethi

Xoxani ngomphumo ofanelekileyo womatshini we-laser

Malunga neNgcebiso kunye neNtlanganiso

> Loluphi ulwazi ekufuneka ulunike?

> Ulwazi lwethu loqhagamshelwano

UMSEBENZI

7. Ungayisebenzisa njani iLaser Cutting Machine?

Umatshini wokusika iLaser ngumatshini okrelekrele nozenzekelayo, ngenkxaso yenkqubo ye-CNC kunye nesoftware yokusika ilaser, umatshini welaser unokujongana nemizobo entsonkothileyo kwaye ucebe indlela efanelekileyo yokusika ngokuzenzekelayo. Udinga nje ukungenisa ifayile yokusika kwinkqubo yelaser, ukhethe okanye usete iiparameter zokusika ilaser ezifana nesantya namandla, kwaye ucinezele iqhosha lokuqala. Umsiki welaser uza kugqiba yonke inkqubo yokusika. Ngenxa yomphetho ogqibeleleyo wokusika onomphetho ogudileyo kunye nomphezulu ococekileyo, akufuneki uchebe okanye upholishe iziqwenga ezigqityiweyo. Inkqubo yokusika ilaser ikhawuleza kwaye umsebenzi ulula kwaye unobuhlobo kwabaqalayo.

▶ Umzekelo 1: Ilaphu Lokusika Nge-Laser

Inyathelo 1. Beka iRoll Fabric kwi-Auto-Feeder

Lungisa iLaphu:Beka ilaphu eliqengqelekayo kwinkqubo yokondla ngokuzenzekelayo, gcina ilaphu lithe tyaba kwaye licocekile, uze uqalise i-auto feeder, ubeke ilaphu eliqengqelekayo kwitafile yokuguqula.

Umatshini weLaser:Khetha umatshini wokusika ilaphu nge-laser one-auto feeder kunye netafile yokuhambisa. Indawo yokusebenza yomatshini kufuneka ihambelane nefomathi yelaphu.

▶

Inyathelo lesi-2. Ngenisa ifayile yokusika kwaye usete iiparameter ze-laser

Ifayile yoYilo:Ngenisa ifayile yokusika kwisoftware yokusika nge-laser.

Seta iiParamitha:Ngokubanzi, kufuneka usete amandla e-laser kunye nesantya se-laser ngokwemilinganiselo yobukhulu bezinto, uxinano, kunye neemfuno zokusika ngokuchanekileyo. Izinto ezincinci zifuna amandla aphantsi, ungavavanya isantya se-laser ukuze ufumane isiphumo esifanelekileyo sokusika.

▶

Inyathelo lesi-3. Qala iLaser Cutting Fabric

Ukusika ngeLaser:Ifumaneka kwiintloko ezininzi zokusika nge-laser, ungakhetha iintloko ezimbini ze-laser kwi-gantry enye, okanye iintloko ezimbini ze-laser kwi-gantry ezimbini ezizimeleyo. Oko kwahlukile kwimveliso yokusika nge-laser. Kuya kufuneka uxoxe nengcali yethu ye-laser malunga nepateni yakho yokusika.

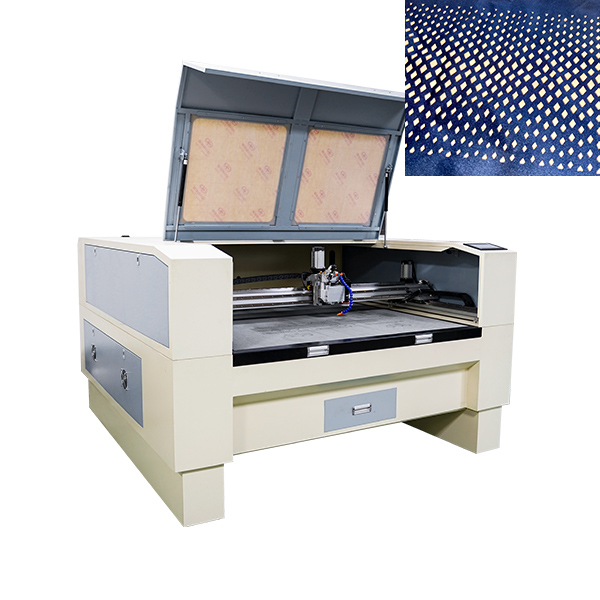

▶ Umzekelo 2: I-Acrylic Eprintiweyo Yokusika Nge-Laser

Inyathelo 1. Beka iphepha le-Acrylic kwiTheyibhile yokuSebenza

Beka Izinto Eziyimfuneko:Beka i-acrylic eprintiweyo etafileni yokusebenza, ukuze sinqumle i-acrylic nge-laser, sisebenzise itafile yokusika imicu yemela enokuthintela ukuba izinto zingatshi.

Umatshini weLaser:Sicebisa ukuba kusetyenziswe i-acrylic laser engraver 13090 okanye i-laser cutter enkulu 130250 ukusika i-acrylic. Ngenxa yepateni eprintiweyo, kufuneka ikhamera ye-CCD ukuqinisekisa ukusika ngokuchanekileyo.

▶

Inyathelo lesi-2. Ngenisa ifayile yokusika kwaye usete iiparameter ze-laser

Ifayile yoYilo:Ngenisa ifayile yokusika kwisoftware yokuqaphela ikhamera.

Seta iiParamitha:INgokubanzi, kufuneka usete amandla e-laser kunye nesantya se-laser ngokwemilinganiselo yobukhulu bezinto, uxinano, kunye neemfuno zokusika ngokuchanekileyo. Izinto ezincinci zifuna amandla aphantsi, ungavavanya isantya se-laser ukuze ufumane isiphumo esifanelekileyo sokusika.

▶

Inyathelo lesi-3. Ikhamera ye-CCD Qaphela iPateni eprintiweyo

Ukuqatshelwa kweKhamera:Kwizinto eziprintiweyo ezifana nelaphu le-acrylic eliprintiweyo okanye ilaphu le-sublimation, inkqubo yokuqaphela ikhamera iyadingeka ukuze iqaphele kwaye ibeke ipateni, kwaye iyalele intloko ye-laser ukuba isike ecaleni kwendlela echanekileyo.

Inyathelo lesi-4. Qala ukusika ngeLaser ecaleni kwePattern Contour

Ukusika ngeLaser:BNjengoko ikhamera ibekwe kwindawo yayo, intloko yokusika nge-laser ifumana indawo efanelekileyo ize iqale ukusika ngokwendlela ebekwe ngayo. Yonke inkqubo yokusika izenzekela kwaye iyahambelana.

▶ Iingcebiso kunye namaqhinga xa usikwa ngeLaser

✦ Ukukhetha Izinto:

Ukuze ufumane isiphumo esifanelekileyo sokusika nge-laser, kufuneka uyiphathe kakuhle le nto kwangaphambili. Ukugcina le nto ithe tyaba kwaye icocekile kuyimfuneko ukuze ubude bokusika nge-laser bufane ukuze isiphumo sokusika sihlale silungile. Kukho iintlobo ezininzi ezahlukeneyoizixhoboezinokusikwa kwaye ziqoshwe nge-laser, kwaye iindlela zangaphambi konyango zahlukile, ukuba usandul' ukufika koku, ukuthetha nengcali yethu ye-laser lolona khetho lufanelekileyo.

✦Uvavanyo Lokuqala:

Yenza uvavanyo lwelaser usebenzisa ezinye iisampuli, ngokuseta amandla ahlukeneyo elaser, isantya selaser ukuze ufumane iiparameter zelaser ezifanelekileyo, ukuze ufumane isiphumo esigqibeleleyo sokusika esihlangabezana neemfuno zakho.

✦Umoya ongenisayo:

Izinto zokusika nge-laser zinokuvelisa umsi kunye negesi emdaka, ngoko ke kufuneka inkqubo yokungenisa umoya esebenza kakuhle. Sidla ngokuxhobisa ifeni yokukhupha umoya ngokwendawo yokusebenza, ubungakanani bomatshini, kunye nezinto zokusika.

✦ Ukhuseleko lweMveliso

Kwizinto ezikhethekileyo ezifana nezinto ezidityanisiweyo okanye izinto zeplastiki, sicebisa abathengi ukuba baxhobiseisixhobo sokukhupha umsikumatshini wokusika nge-laser. Oko kungenza indawo yokusebenza icoceke kwaye ikhuseleke ngakumbi.

✦ Fumana i-Laser Focus:

Qinisekisa ukuba umqadi welaser ugxile ngokufanelekileyo kumphezulu wezinto ezibonakalayo. Ungasebenzisa ezi ndlela zilandelayo zokuvavanya ukufumana ubude obuchanekileyo be-laser focal, kwaye ulungise umgama ukusuka entlokweni yelaser ukuya kumphezulu wezinto ezibonakalayo ngaphakathi koluhlu oluthile olujikeleze ubude obuphambili, ukuze ufikelele kwisiphumo esifanelekileyo sokusika nokukrola. Kukho umahluko phakathi kokusika kwelaser kunye nokukrola kwelaser. Ukuze ufumane iinkcukacha malunga nendlela yokufumana ubude obufanelekileyo be-focal, nceda ujonge ividiyo >>

Isifundo sevidiyo: Ungayifumana njani ingqwalasela echanekileyo?

▶ Nyamekela i-Water Chiller yakho

Isixhobo sokuphola amanzi kufuneka sisetyenziswe kwindawo enomoya opholileyo nepholileyo. Kwaye itanki yamanzi kufuneka icocwe rhoqo kwaye amanzi kufuneka atshintshwe rhoqo emva kweenyanga ezi-3. Ebusika, ukongeza i-antifreeze kwisixhobo sokuphola amanzi kuyimfuneko ukuthintela ukubanda. Funda ngakumbi malunga nendlela yokugcina ukubanda kwamanzi ebusika, nceda ujonge iphepha:Amanyathelo Okumelana Nokuqandisa Kwi-Laser Cutter Ebusika

▶ Coca iilensi zokugxila kunye nezipili

Xa kusikwa kwaye kukrolwa nge-laser ezinye izinto, umsi, inkunkuma, kunye ne-resin ziya kuveliswa zize zishiywe kwizipili nakwilensi. Inkunkuma eqokelelweyo ivelisa ubushushu obonakalisa ilensi kunye nezipili, kwaye inefuthe ekuphumeni kwamandla nge-laser. Ngoko ke ukucoca ilensi yokugxila kunye nezipili kuyimfuneko. Nciphisa i-cotton swab emanzini okanye kwi-alcohol ukuze usule umphezulu welensi, khumbula ukuba ungachukumisi umphezulu ngezandla zakho. Kukho isikhokelo sevidiyo malunga noko, jonga oku >>

▶ Gcina iTheyibhile yokusebenzela icocekile

Ukugcina itafile yokusebenza icocekile kubalulekile ukuze kubekho indawo yokusebenza ecocekileyo nethe tyaba yezixhobo kunye nentloko yokusika nge-laser. I-resin kunye nentsalela azigcini nje ngokungcolisa izinto, kodwa zichaphazela nesiphumo sokusika. Ngaphambi kokucoca itafile yokusebenza, kufuneka ucime umatshini. Emva koko sebenzisa i-vacuum cleaner ukususa uthuli kunye nenkunkuma eseleyo etafileni yokusebenza uze uyishiye kwibhokisi yokuqokelela inkunkuma. Kwaye ucoce itafile yokusebenza kunye nereyile ngetawuli yekotoni efunxwe yi-cleaner. Ulinde itafile yokusebenza ukuba yome, uze ufake umbane.

▶ Coca ibhokisi yokuqokelelwa kothuli

Coca ibhokisi yokuqokelelwa kothuli yonke imihla. Ezinye izinto ezimdaka kunye nentsalela eziveliswa zizinto zokusika nge-laser ziwela kwibhokisi yokuqokelelwa kothuli. Kuya kufuneka ucoce ibhokisi izihlandlo ezininzi emini ukuba ubungakanani bemveliso bukhulu.

• Qinisekisa rhoqo ukubaiindawo zokhuseleko ezinxibelelanayozisebenza kakuhle. Qinisekisa ukubaiqhosha lokumisa ngexesha likaxakeka, isibane sesiginaliziqhuba kakuhle.

•Faka umatshini phantsi kwesikhokelo sengcali yelaser.Ungaze uvule umatshini wakho wokusika nge-laser de ube udityaniswe ngokupheleleyo kwaye zonke izigqubuthelo zibekwe endaweni yazo.

•Musa ukusebenzisa isixhobo sokusika kunye nomkroli welaser kufutshane nayo nayiphi na indawo enokubakho yobushushu.Soloko ugcina indawo ejikeleze isixhobo sokusika ingenazo iingceba, izinto ezingafunekiyo, nezinto ezinokutsha.

• Musa ukuzama ukulungisa umatshini wokusika nge-laser wedwa -fumana uncedo lweengcalievela kwingcali yelaser.

•Sebenzisa izixhobo zokhuseleko lwelaserEzinye izinto ezikroliweyo, eziphawulweyo, okanye ezisikiweyo nge-laser zinokuvelisa umsi onobuthi nongcolisayo. Ukuba awuqinisekanga, nceda uqhagamshelane nengcali yakho ye-laser.

•UNGAZE usebenzise inkqubo ngaphandle kwegadiQinisekisa ukuba umatshini welaser usebenza phantsi kweliso lomntu.

• AInto yokucima umliloIfanele ifakwe eludongeni kufutshane ne-Laser Cutter.

• Emva kokusika ezinye izinto zokuhambisa ubushushu,ndidinga ii-tweezers okanye iiglavu eziqinileyo ukuze ndithathe izinto ezisetyenzisiweyo.

• Kwezinye izinto ezifana neplastiki, ukusika nge-laser kunokubangela umsi omninzi nothuli olungavumelekanga kwindawo osebenza kuyo.isixhobo sokukhupha umsiyeyona ndlela ilungileyo onokukhetha kuyo, enokufunxa kwaye icoce inkunkuma, iqinisekise ukuba indawo yokusebenza icocekile kwaye ikhuselekile.

•Iiglasi zokhuseleko ze-laserzineelensi ezenzelwe ngokukodwa ezinombala ukuze zifunxe ukukhanya kwelaser kwaye zithintele ukuba kungadluli emehlweni omntu oyinxibileyo. Iiglasi kufuneka zihambelane nohlobo lwelaser (kunye nobude be-wavelength) oyisebenzisayo. Zikwanemibala eyahlukeneyo ngokwe-wavelength eziyifunxayo: luhlaza okwesibhakabhaka okanye oluhlaza kwiilaser ze-diode, ngwevu kwiilaser ze-CO2, kunye noluhlaza olukhanyayo kwiilaser zefayibha.

FAQ

• Ixabisa malini umatshini wokusika nge-laser?

Ii-CO2 laser cutters ezisisiseko ziqala ngaphantsi kwe-$2,000 ukuya ngaphezulu kwe-$200,000. Umahluko wexabiso mkhulu kakhulu xa kufikwa kwiindlela ezahlukeneyo zokusika ii-CO2 laser cutters. Ukuze uqonde ixabiso lomatshini we-laser, kufuneka ucinge ngaphezu kwexabiso lokuqala. Kufuneka uqwalasele neendleko zizonke zokuba nomatshini we-laser ubomi bawo bonke, ukuze uvavanye ngcono ukuba kufanelekile na ukutyala imali kwisixhobo se-laser. Iinkcukacha malunga namaxabiso omatshini wokusika ii-laser ukujonga iphepha:Ixabisa malini imatshini yelaser?

• Usebenza njani umatshini wokusika nge-laser?

Umqadi welaser uqala kumthombo welaser, kwaye uqondiswa kwaye ujoliswe zizipili kunye nelensi yokugxila ukuya entlokweni yelaser, uze uthwelwe kwizinto. Inkqubo ye-CNC ilawula ukuveliswa komqadi welaser, amandla kunye nokubetha kwelaser, kunye nendlela yokusika yentloko yelaser. Idityaniswe ne-air blower, ifeni yokukhupha umoya, isixhobo sokuhamba kunye netafile yokusebenza, inkqubo yokusika ilaser esisiseko inokugqitywa kakuhle.

• Yeyiphi igesi esetyenziswa kumatshini wokusika nge-laser?

Kukho iindawo ezimbini ezifuna igesi: i-resonator kunye nentloko yokusika nge-laser. Kwi-resonator, igesi equka i-CO2 ephezulu (ibanga lesi-5 okanye ngaphezulu) iyadingeka ukuvelisa umqadi we-laser. Kodwa ngokuqhelekileyo, akufuneki utshintshe ezi gesi. Kwintloko yokusika, igesi yokuncedisa i-nitrogen okanye i-oxygen iyadingeka ukunceda ukukhusela izinto eziza kucutshungulwa kunye nokuphucula umqadi we-laser ukufikelela kwisiphumo esifanelekileyo sokusika.

• Yintoni umahluko: Umsiki weLaser vs Umsiki weLaser?

Malunga neMimoWork Laser

I-Mimowork ngumvelisi we-laser ojolise kwiziphumo, oseShanghai naseDongguan eTshayina, ozisa iminyaka engama-20 yobuchule obunzulu bokusebenza ukuvelisa iinkqubo ze-laser nokubonelela ngezisombululo ezipheleleyo zokucubungula kunye nemveliso kwii-SME (amashishini amancinci naphakathi) kuluhlu olubanzi lwamashishini.

Amava ethu atyebileyo kwizisombululo ze-laser zokucubungula izinto zesinyithi nezingezizo zesinyithi asekelwe nzulu kwihlabathi liphela.intengiso, iimoto kunye neenqwelo moya, izixhobo zentsimbi, izicelo ze-dye sublimation, ilaphu kunye neempahlaamashishini.

Endaweni yokubonelela ngesisombululo esingaqinisekanga esifuna ukuthengwa kubavelisi abangafanelekanga, iMimoWork ilawula yonke inxalenye yekhonkco lemveliso ukuqinisekisa ukuba iimveliso zethu zisebenza kakuhle rhoqo.

Funda Okungakumbi Ngokukhawuleza:

Ngena kwihlabathi lomlingo lomatshini wokusika nge-laser,

Xoxa neNgcali yethu yeLaser!

Ixesha leposi: Meyi-27-2024