Xa usandul’ ukuqalisa ukusebenzisa ubuchwepheshe be-laser kwaye ucinga ngokuthenga umatshini wokusika nge-laser, kufuneka ukuba kukho imibuzo emininzi ofuna ukuyibuza.

I-MimoWorkIngavuya ukwabelana nawe ngolwazi oluthe kratya malunga noomatshini be-laser be-CO2 kwaye ngethemba lokuba ungafumana isixhobo esikufaneleyo, nokuba sivela kuthi okanye komnye umthengisi we-laser.

Kweli nqaku, siza kubonelela ngesishwankathelo esifutshane soqwalaselo lomatshini kwindawo eqhelekileyo size senze uhlalutyo oluthelekisayo lwecandelo ngalinye. Ngokubanzi, eli nqaku liza kugubungela amanqaku ngolu hlobo lulandelayo:

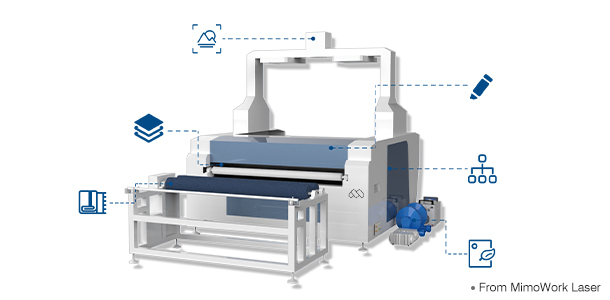

Iinkqubo zomatshini we-laser we-CO2

a. Imoto ye-DC engenabhrashi, iMoto yeServo, iMoto yeStep

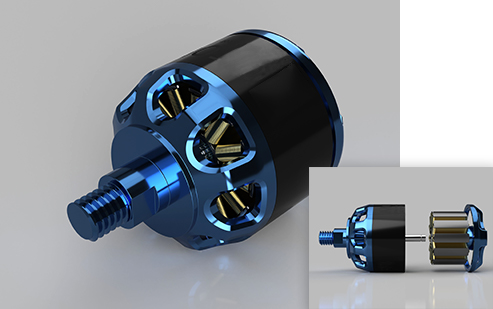

Injini ye-DC engenabhrashi (eyangoku ngqo) engenamandla

Imoto ye-DC engenabhrashi ingasebenza kwi-RPM ephezulu (iinguqu ngomzuzu). I-stator yemoto ye-DC inika amandla emagnethi ajikelezayo aqhuba i-armature ukuba ijikeleze. Phakathi kwazo zonke iimoto, imoto ye-dc engenabhrashi inokubonelela ngamandla e-kinetic anamandla kwaye iqhube intloko ye-laser ukuba ihambe ngesantya esikhulu.Umatshini wokukrola we-CO2 ongcono kakhulu weMimoWork ixhotyiswe ngemoto engenamabhrashi kwaye inokufikelela kwisantya esiphezulu sokukrola se-2000mm/s.I-motor ye-dc engenamabhrashi ayifumaneki rhoqo kumatshini wokusika nge-laser ye-CO2. Oku kungenxa yokuba isantya sokusika izinto sinqunyelwe bubukhulu bezinto. Ngokwahlukileyo koko, udinga amandla amancinci kuphela ukuze ukrole imifanekiso kwizinto zakho, I-motor engenamabhrashi exhotyiswe ngomkroli we-laser iyanciphisa ixesha lakho lokukrola ngokuchanekileyo ngakumbi.

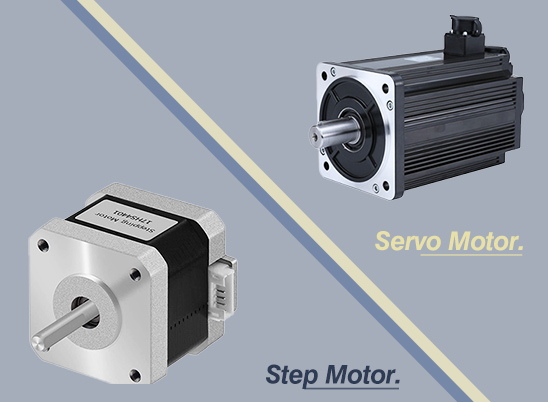

Imoto yeServo kunye neMoto yeStep

Xa zidibene netafile ye-CO2 laser engraver, ii-servo motors zibonelela nge-torque ephezulu kunye nokuchaneka, ngakumbi kwimisebenzi yobugcisa efana nokusika ilaphu lesihluzo okanye izigqubuthelo ze-insulation. Nangona zibiza kakhulu kwaye zifuna ii-encoders kunye nee-gearbox—okwenza ukuseta kube nzima ngakumbi—zilungele ukusetyenziswa okungafunekiyo. Oko kuthethiweyo, ukuba wenza izipho ezilula zobugcisa okanye imiqondiso, i-stepper motor kwitafile yakho ye-laser engraver idla ngokwenza umsebenzi kakuhle.

Injini nganye ineengenelo kunye neengozi zayo. Le ikufanelayo yeyona ilungileyo kuwe.

Ngokuqinisekileyo, iMimoWork inokubonelelaUmkroli kunye nomsiki we-laser we-CO2 eneentlobo ezintathu zemotongokusekelwe kwimfuno yakho kunye nohlahlo lwabiwo-mali.

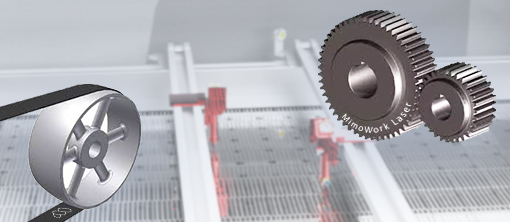

b. I-Belt Drive vs I-Gear Drive

I-belt drive isebenzisa i-belt ukudibanisa amavili, ngelixa i-gear drive idibanisa ii-gear ngokuthe ngqo ngamazinyo adibeneyo. Kwiimashini ze-laser, zombini ezi nkqubo zinceda ukuhambisa i-gantry kwaye zichaphazele indlela umatshini onokuba ngokuchanekileyo ngayo.

Masithelekise ezi zimbini nale theyibhile ilandelayo:

| I-Belt Drive | I-Gear Drive |

| Izinto eziphambili: iiPulleys kunye neBelt | Izinto eziphambili zeGiya |

| Kufuneka indawo engakumbi | Kufuneka indawo encinci, ngoko ke umatshini welaser unokuyilwa ukuba ube mncinci |

| Ukulahleka okukhulu kokungqubana, ngoko ke ukudluliselwa okuphantsi kunye nokusebenza kancinci | Ukulahleka okuphantsi kokungqubana, ngoko ke ukudluliselwa okuphezulu kunye nokusebenza kakuhle ngakumbi |

| Ixesha lokuphila eliphantsi kunee-gear drives, zihlala zitshintsha rhoqo emva kweminyaka emi-3 | Ixesha lokuphila liphezulu kakhulu kunee-belt drives, zihlala zitshintsha rhoqo emva kweminyaka elishumi |

| Ifuna ukulungiswa okungakumbi, kodwa iindleko zokulungisa ziphantsi kwaye zilula | Ifuna ukulungiswa okuncinci, kodwa iindleko zokulungisa zibiza kakhulu kwaye zinzima |

| Akufuneki ukuthambisa | Funa ukuthambisa rhoqo |

| Isebenza ngokuthula kakhulu | Ingxolo iyasebenza |

Zombini iinkqubo zokuqhuba igiya kunye ne-belt drive zihlala ziyilelwe kumatshini wokusika nge-laser kunye neengenelo kunye neengxaki. Ngamafutshane,Inkqubo yokuqhuba ibhanti iluncedo ngakumbi kwiintlobo zoomatshini abancinci, ababhabhayo nababonayongenxa yokudluliselwa okuphezulu kunye nokuqina,i-gear drive ifanelekile ngakumbi kwi-laser cutter enefomathi enkulu, ngesiqhelo inoyilo lwe-hybrid optical.

c. Itheyibhile Yokusebenza Engashukumiyo VS Itheyibhile Yokusebenza YeConveyor

Ukuze uphucule indlela esebenza ngayo i-laser, udinga okungaphezulu kobonelelo lwe-laser olukumgangatho ophezulu kunye nenkqubo yokuqhuba egqwesileyo yokuhambisa intloko ye-laser, itafile efanelekileyo yokuxhasa izinto nayo iyafuneka. Itafile yokusebenza eyenzelwe ukuhambelana nezinto okanye usetyenziso ithetha ukuba unokwandisa amandla omatshini wakho we-laser.

Ngokubanzi, kukho iindidi ezimbini zamaqonga okusebenza: i-Stationary kunye ne-Mobile.

(Kwizicelo ezahlukeneyo, ungagqibela usebenzisa zonke iintlobo zezinto, nokubaizinto ezifakwe ephepheni okanye izinto ezijijekileyo)

○Itafile Yokusebenza Engashukumiyoilungele ukubeka izinto zephepha ezifana ne-acrylic, umthi, iphepha (ikhadibhodi).

• itafile yokuqhawula imimese

• itafile yekama yobusi

○Itafile Yokusebenza Yomthuthiilungele ukubeka izinto ezisongwayo ezifana nelaphu, ulusu, igwebu.

• itafile yesithuthi

• itafile yokuhambisa

Iingenelo zoyilo olufanelekileyo lwetafile yokusebenza

✔Ukukhupha kakuhle ukukhutshwa komoya ongcolileyo

✔Zinzisa izinto, akukho kushenxa okwenzekayo xa usika

✔Kulula ukulayisha nokukhulula izinto zokusebenza

✔Isikhokelo esifanelekileyo sokugxila ngenxa yeendawo ezithe tyaba

✔Ukunyamekela nokucoca okulula

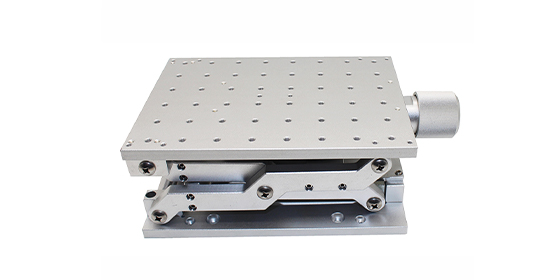

d. Iqonga Lokuphakamisa Ngokuzenzekelayo VS Lokuphakamisa Ngesandla

Xa ukrola izinto eziqinileyo, ezifanai-acrylic (PMMA)kwayeumthi (MDF), izixhobo ziyahluka ngobukhulu. Ukuphakama okufanelekileyo kokugxila kunokuphucula isiphumo sokukrola. Iqonga lokusebenza elihlengahlengiswayo liyimfuneko ukuze kufunyanwe indawo encinci yokugxila. Kumatshini wokukrola we-laser we-CO2, amaqonga okuphakamisa ngokuzenzekelayo kunye namaqonga okuphakamisa ngesandla adla ngokuthelekiswa. Ukuba uhlahlo lwabiwo-mali lwakho lwanele, khetha amaqonga okuphakamisa ngokuzenzekelayo.Ayiphuculi nje kuphela ukuchaneka kokusika nokukrola, kodwa inokukongela ixesha elininzi kunye nomgudu.

e. Inkqubo yokungenisa umoya ephezulu, ecaleni nasezantsi

Inkqubo yokungenisa umoya esezantsi yeyona ndlela ixhaphakileyo yomatshini we-laser we-CO2, kodwa iMimoWork ikwanazo nezinye iintlobo zoyilo zokuphucula amava okucubungula i-laser.umatshini wokusika we-laser omkhulu, iMimoWork iza kusebenzisa i-combinedinkqubo edinisayo ephezulu nesezantsiukunyusa isiphumo sokukhupha ngelixa kugcinwa iziphumo zokusika nge-laser ezikumgangatho ophezulu. Uninzi lwethuumatshini wokumakisha we-galvo, siza kufakainkqubo yokungenisa umoya ecaleniukukhupha umsi. Zonke iinkcukacha zomatshini kufuneka zijoliswe ngcono ekusombululeni iingxaki zomzi-mveliso ngamnye.

An inkqubo yokukhuphaiveliswa phantsi kwezinto ezisetyenziswa ngomatshini. Ayikhuphi nje kuphela umsi oveliswa kunyango lobushushu kodwa ikwaqinisa izinto, ingakumbi ilaphu elilula. Okukhona inxalenye enkulu yomphezulu wokucubungula egqunywe zizinto ezicutshungulwayo, kokukhona isiphumo sokufunxa siphezulu kwaye i-vacuum yokufunxa isiphumo sayo siphezulu.

Iityhubhu zeglasi ze-laser ze-CO2 VS iityhubhu ze-laser ze-CO2 RF

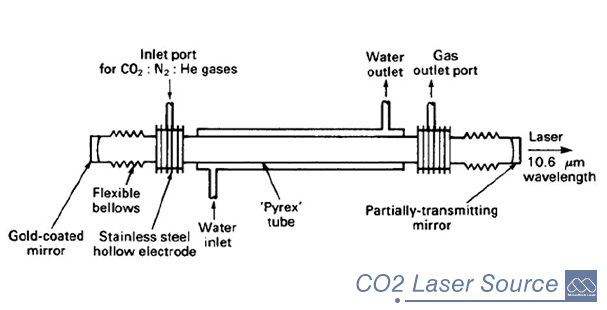

a. Umgaqo wokuvuselela we-laser ye-CO2

Ilaser yekhabhoni diokside yayiyenye yeelaser zegesi zokuqala ukuphuhliswa. Ngeminyaka emininzi yophuhliso, obu buchwephesha sele bukhulile kwaye banele ukusetyenziswa ngeendlela ezininzi. Ityhubhu yelaser ye-CO2 iyayivuselela le laser ngomgaqo weukukhupha ukukhanyakwayeiguqula amandla ombane abe ngamandla okukhanya aqinileyoNgokusebenzisa i-voltage ephezulu kwi-carbon dioxide (i-laser medium esebenzayo) kunye nenye igesi ngaphakathi kwityhubhu ye-laser, igesi ivelisa ukukhupha ukukhanya kwaye iqhubeka ivuselelwa kwisikhongozeli phakathi kwezipili ezibonisa ukukhanya apho izibuko zibekwe kumacala omabini enqanawa ukuvelisa i-laser.

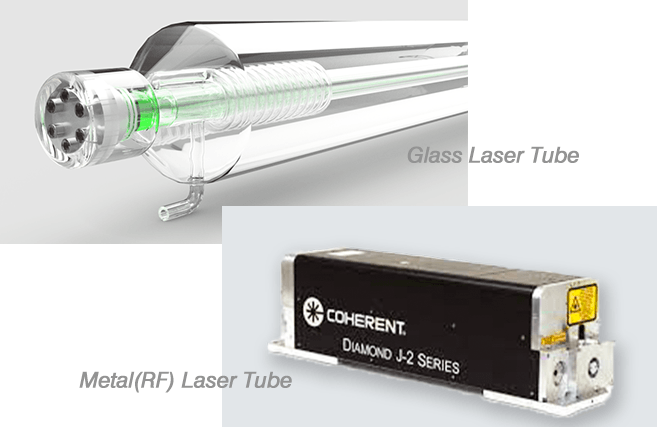

b. Umahluko wetyhubhu yelaser yeglasi ye-CO2 kunye netyhubhu yelaser ye-CO2 RF

Ukuba ufuna ukuqonda ngakumbi ngomatshini we-laser we-CO2, kuya kufuneka ujonge iinkcukacha zeumthombo welezaNjengohlobo lwelaser olufanelekileyo kakhulu ukucubungula izinto ezingezizo ezesinyithi, umthombo welaser we-CO2 unokwahlulwa ube ziiteknoloji ezimbini eziphambili:Ityhubhu yeLaser yeglasikwayeItyhubhu yeLaser yesinyithi yeRF.

(Ngendlela, i-laser ye-CO2 enamandla aphezulu akhawulezayo kunye ne-laser ye-CO2 ehamba kancinci azikho kwingxoxo yethu yanamhlanje)

| Iityhubhu zeLaser zeGlasi (DC) | Iityhubhu zeLaser zeMetal (RF) | |

| Umsebenzi wobomi | Iiyure ezingama-2500-3500 | Iiyure ezingama-20,000 |

| Uphawu | IsiTshayina | Ihambelanayo |

| Indlela Yokupholisa | Ukupholisa Amanzi | Ukupholisa Amanzi |

| Ingatshajwa kwakhona | Hayi, yisebenzise kube kanye kuphela | Ewe |

| Iwaranti | Iinyanga ezi-6 | Iinyanga ezili-12 |

Inkqubo yoLawulo kunye neSoftware

Isoftware yomatshini wokusika i-laser ye-CO2 isebenza njengengqondo yenkqubo, isebenzisa inkqubo ye-CNC ukukhokela intshukumo ye-laser kunye nokulungisa amanqanaba amandla. Ivumela imveliso eguquguqukayo ngokukuvumela ukuba utshintshe uyilo ngokukhawuleza kwaye uphathe izixhobo ezahlukeneyo—ngokulungisa amandla e-laser kunye nesantya sokusika, akukho mfuneko yokutshintsha izixhobo.

Uninzi lwabantu abakwimarike baya kuthelekisa iteknoloji yesoftware yaseTshayina kunye neteknoloji yesoftware yeenkampani ze-laser zaseYurophu naseMelika. Ukuze ufumane ipateni yokusika nokukrola, ii-algorithms zesoftware ezininzi ezikwimarike azifani kakhulu. Ngeminyaka emininzi yengxelo yedatha evela kubavelisi abaninzi, isoftware yethu ineempawu ezilandelayo:

1. Kulula ukuyisebenzisa

2. Ukusebenza okuzinzileyo nokukhuselekileyo kwixesha elide

3. Vavanya ixesha lemveliso ngokufanelekileyo

4. Xhasa i-DXF, i-AI, i-PLT kunye nezinye iifayile ezininzi

5. Ngenisa iifayile zokusika ezininzi ngexesha elinye kunye namathuba okuguqula

6. Cwangcisa ngokuzenzekelayo iipateni zokusika ngeekholamu kunye nemigcaI-Mimo-Nest

Ngaphandle kwesiseko sesoftware yokusika eqhelekileyo,Inkqubo yokuQondwa koMbonoinokuphucula izinga lokwenziwa kwezinto ngokuzenzekelayo kwimveliso, inciphise umsebenzi kwaye iphucule ukuchaneka kokusika. Ngamazwi alula, i-CCD Camera okanye i-HD Camera efakwe kumatshini we-laser we-CO2 isebenza njengamehlo omntu kwaye iyala umatshini we-laser apho kufuneka usike khona. Le teknoloji isetyenziswa rhoqo kwizicelo zokuprinta zedijithali kunye neendawo zokuhombisa, ezifana nemidlalo ye-dye-sublimation, iiflegi zangaphandle, ii-embroidery patches kunye nezinye ezininzi. Kukho iintlobo ezintathu zeendlela zokuqaphela umbono ezinokuthi zibonelelwe yiMimoWork:

▮ Ukuqatshelwa kweContour

Ukuprinta ngedijithali nange-sublimation kuyanda, ngakumbi kwiimveliso ezifana neempahla zemidlalo, iibhanile, kunye nee-teardrops. La malaphu aprintiweyo awanakunqunyulwa ngokuchanekileyo ngesikere okanye iiblade zemveli. Kulapho iinkqubo ze-laser ezisekelwe kumbono zikhanya khona. Usebenzisa ikhamera enesisombululo esiphezulu, umatshini ubamba ipateni aze azinqumle ngokuzenzekelayo ecaleni komda wayo—akukho mfuneko yokusika ifayile okanye ukusika ngesandla. Oku akuphuculi nje kuphela ukuchaneka kodwa kukhawulezisa imveliso.

Isikhokelo sokuSebenza:

1. Yondla iimveliso ezineepateni >

2. Thatha ifoto yepateni >

3. Qalisa ukusika i-contour laser >

4. Qokelela ezigqityiweyo >

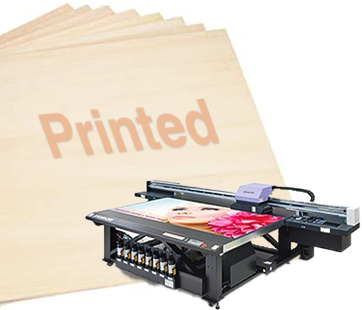

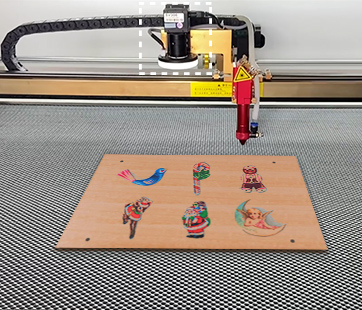

▮ Inqaku lophawu lobhaliso

Ikhamera yeCCDunokubona aze afumane ipateni eprintiweyo kwibhodi yomthi ukunceda i-laser ngokusika ngokuchanekileyo. Iimpawu zomthi, iiplaque, umsebenzi wobugcisa kunye nefoto yomthi eyenziwe ngomthi oprintiweyo zinokucutshungulwa ngokulula.

Inyathelo 1.

>> Phrinta ngqo ipateni yakho ebhodini lomthi

Inyathelo lesi-2.

>> Ikhamera yeCCD inceda i-laser ukusika uyilo lwakho

Inyathelo lesi-3.

>> Qokelela izinto zakho ezigqityiweyo

▮ Ukuthelekiswa kweTemplate

Kwiipetshi ezithile, iilebhile, iifoyile eziprintiweyo ezinobukhulu obufanayo kunye nepateni, iTemplate Matching Vision System evela kwiMimoWork iya kuba luncedo olukhulu. Inkqubo yelaser ingasika ngokuchanekileyo ipateni encinci ngokuqaphela nokubeka itemplate esetiweyo eyifayile yokusika uyilo ukuze ihambelane nenxalenye yeempawu zeepetshi ezahlukeneyo. Nayiphi na ipateni, ilogo, umbhalo okanye enye inxalenye ebonakalayo ebonwayo inokuba yinxalenye yeempawu.

Iinketho zeLaser

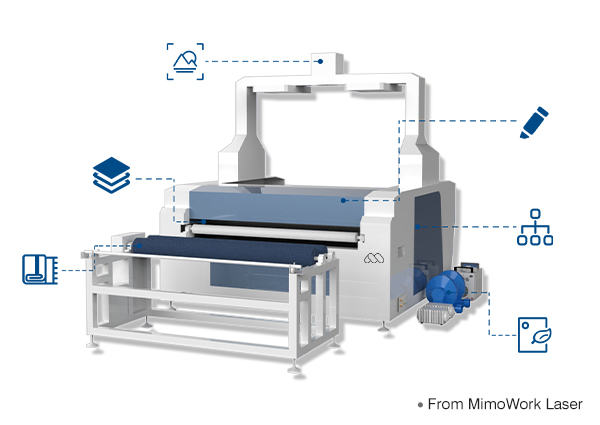

I-MimoWork inikezela ngeendlela ezininzi ezongezelelweyo kuzo zonke izixhobo zokusika i-laser ezisisiseko ngokungqongqo ngokwesicelo ngasinye. Kwinkqubo yemveliso yemihla ngemihla, ezi zakhiwo ezenziwe ngokwezifiso kumatshini we-laser zijolise ekunyuseni umgangatho wemveliso kunye nokuguquguquka ngokweemfuno zemarike. Eyona khonkco ibalulekileyo kunxibelelwano lwasekuqaleni nathi kukwazi imeko yakho yemveliso, zeziphi izixhobo ezisetyenziswayo ngoku kwimveliso, kunye neengxaki ezidibana nazo kwimveliso. Ngoko ke masizazise ezinye izinto ezimbalwa eziqhelekileyo ezikhethwayo ezikhethwayo.

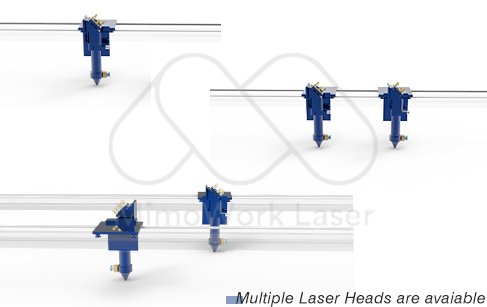

a. Iintloko ezininzi ze-laser onokukhetha kuzo

Ukongeza iintloko ezininzi ze-laser kunye neetyhubhu kumatshini omnye yindlela elula nengabizi kakhulu yokunyusa imveliso. Igcina utyalo-mali kunye nendawo yomgangatho xa kuthelekiswa nokuthenga oomatshini abahlukeneyo. Kodwa ayisoloko ifanelekile. Kuya kufuneka uqwalasele ubungakanani betafile yakho yokusebenza kunye neepateni zokusika. Yiyo loo nto sihlala sicela abathengi ukuba babelane ngoyilo lweesampuli ngaphambi kokuba bafake iodolo.

Imibuzo engakumbi malunga nokugcinwa komatshini welaser okanye ilaser

Ixesha lokuthumela: Oktobha-12-2021