ISINGENISO SOKUSIKWA KWE-LASER

Kunezinhlelo zokusebenza ze-laser ezahlukahlukene kusukela kupeni le-laser lesifundo kuya ezikhalini ze-laser zokushaya okude. Ukusika nge-Laser, njengesigaba sezinhlelo zokusebenza, kuye kwathuthukiswa futhi kwagqama emikhakheni yokusika nokuqopha. Ngezici ezinhle kakhulu ze-laser, ukusebenza okuhle kakhulu kokusika, kanye nokucubungula okuzenzakalelayo, imishini yokusika nge-laser ithatha indawo yamathuluzi athile okusika endabuko. I-CO2 Laser iyindlela yokucubungula ethandwa kakhulu. Ubude be-wavelength obungu-10.6μm buhambisana cishe nazo zonke izinto ezingezona ezensimbi kanye nensimbi eqinisiwe. Kusukela endwangu yansuku zonke kanye nesikhumba, kuya epulasitikini esetshenziswa ezimbonini, ingilazi, kanye nokushisa, kanye nezinto zokwenza izinto njengokhuni kanye ne-acrylic, umshini wokusika nge-laser uyakwazi ukuphatha lokhu futhi uthole imiphumela emihle kakhulu yokusika. Ngakho-ke, noma ngabe usebenza ngokusika nokuqopha izinto zokusetshenziswa kwezentengiselwano kanye nezimboni, noma ufuna ukutshala imali emshinini omusha wokusika wezinto zokuzilibazisa kanye nomsebenzi wesipho, ukuba nolwazi oluncane ngomshini wokusika nge-laser kanye nomshini wokusika nge-laser kuzoba usizo olukhulu kuwe ukwenza uhlelo.

UBUCHWEPHESHE

1. Uyini Umshini Wokusika Nge-Laser?

Umshini Wokusika I-Laser uwumshini onamandla wokusika nokuqopha olawulwa uhlelo lwe-CNC. Umshini we-laser osheshayo nonamandla uvela eshubhu le-laser lapho kwenzeka khona ukusabela kwe-photoelectric okumangalisayo. Amashubhu e-laser okusika i-LASER ye-CO2 ahlukaniswe izinhlobo ezimbili: amashubhu e-laser engilazi namashubhu e-laser ensimbi. Umshini we-laser okhishwayo uzodluliselwa ezintweni ozosika ngezibuko ezintathu kanye nelensi eyodwa. Akukho ukucindezeleka komshini, futhi akukho ukuxhumana phakathi kwekhanda le-laser nezinto. Lapho nje umshini we-laser ophethe ukushisa okukhulu udlula ezintweni, uyahwamuka noma uncishiswe. Akukho lutho olusele ngaphandle kwe-kerf encane kakhulu ezintweni. Lena inqubo eyisisekelo kanye nomgomo wokusika i-laser ye-CO2. Umshini we-laser onamandla uhambisana nohlelo lwe-CNC kanye nesakhiwo sokuthutha esiyinkimbinkimbi, futhi umshini wokusika i-laser oyisisekelo wakhiwe kahle ukuze usebenze. Ukuqinisekisa ukusebenza okuzinzile, ikhwalithi yokusika ephelele, kanye nokukhiqizwa okuphephile, umshini wokusika i-laser ufakwe uhlelo lokusiza umoya, ifeni yokukhipha umoya, idivayisi yokukhipha, nokunye.

2. Isebenza Kanjani I-Laser Cutter?

Siyazi ukuthi i-laser isebenzisa ukushisa okukhulu ukusika izinto. Pho-ke ubani othumela imiyalelo yokuqondisa indlela ehambayo kanye nendlela yokusika? Yebo, uhlelo lwe-laser lwe-cnc oluhlakaniphile oluhlanganisa isofthiwe yokusika i-laser, ibhodi lokulawula eliyinhloko, uhlelo lwesekethe. Uhlelo lokulawula okuzenzakalelayo lwenza ukusebenza kube lula futhi kube lula, kungakhathaliseki ukuthi ungumqali noma uchwepheshe. Sidinga nje ukungenisa ifayela lokusika bese sibeka amapharamitha e-laser afanele njengejubane namandla, futhi umshini wokusika i-laser uzoqala inqubo elandelayo yokusika ngokwemiyalelo yethu. Yonke inqubo yokusika nokuqopha i-laser iyahambisana futhi inokunemba okuphindaphindiwe. Akumangalisi ukuthi i-laser iyiqhawe lejubane nekhwalithi.

3. Isakhiwo Sokusika Nge-Laser

Ngokuvamile, umshini wokusika nge-laser uqukethe izingxenye ezine eziyinhloko: indawo yokukhipha i-laser, uhlelo lokulawula, uhlelo lokunyakaza, kanye nohlelo lokuphepha. Ingxenye ngayinye idlala indima ebalulekile ekusikeni nasekuqopheni okunembile nokusheshayo. Ukwazi ngezakhiwo ezithile kanye nezingxenye zemishini yokusika nge-laser, akugcini nje ngokukusiza ukuthi wenze isinqumo esifanele lapho ukhetha futhi uthenga umshini, kodwa futhi kunikeza ukuguquguquka okwengeziwe kokusebenza kanye nokwanda kokukhiqiza esikhathini esizayo.

Nasi isingeniso ezingxenyeni eziyinhloko zomshini wokusika nge-laser:

Umthombo We-Laser:

I-CO2 Laser:Isebenzisa ingxube yegesi eyakhiwe ngokuyinhloko yi-carbon dioxide, okwenza ibe yindawo ekahle yokusika izinto ezingezona ezensimbi njengokhuni, i-acrylic, indwangu, kanye nezinhlobo ezithile zamatshe. Isebenza ngobude be-wavelength obungaba ama-micrometer ayi-10.6.

I-Fiber Laser:Isebenzisa ubuchwepheshe be-laser obuqinile obunezintambo ze-optical ezifakwe izinto ezingavamile zomhlaba njenge-ytterbium. Isebenza kahle kakhulu ekusikeni izinsimbi ezifana nensimbi, i-aluminium, nethusi, isebenza ngobude be-wavelength obungaba ama-micrometer angu-1.06.

I-Nd:YAG I-Laser:Isebenzisa ikristalu ye-garnet ye-aluminium ye-yttrium ene-neodymium. Iyakwazi ukuguquguquka futhi ingasika izinsimbi kanye nezinye ezingezona izinsimbi, yize ingavamile kakhulu kune-CO2 kanye ne-fiber lasers yokusika izinhlelo zokusebenza.

Ishubhu ye-Laser:

Igcina indawo ye-laser (igesi ye-CO2, uma kukhulunywa ngama-laser e-CO2) futhi ikhiqiza umsebe we-laser ngokusebenzisa ukuvusa kukagesi. Ubude namandla eshubhu le-laser kunquma amakhono okusika kanye nobukhulu bezinto ezingasikwa. Kunezinhlobo ezimbili zeshubhu le-laser: ishubhu le-laser yengilazi kanye neshubhu le-laser yensimbi. Izinzuzo zamashubhu e-laser yengilazi zilula kakhulu futhi zingaphatha ukusika kwezinto ezilula kakhulu ngaphakathi kobubanzi obuthile bokunemba. Izinzuzo zamashubhu e-laser yensimbi isikhathi eside senkonzo kanye nekhono lokukhiqiza ukunemba okuphezulu kokusika kwe-laser.

Uhlelo Lokubona:

Izibuko:Zibekwe ngendlela efanele ukuze ziqondise umsebe we-laser kusuka epayipini le-laser ziye ekhanda lokusika. Kumelwe ziqondaniswe kahle ukuqinisekisa ukulethwa komsebe okunembile.

Amalensi:Gxilisa umsebe we-laser endaweni encane, uthuthukise ukunemba kokusika. Ubude be-focal belensi buthinta ukugxila komsebe kanye nokujula kokusika.

Ikhanda Lokusika Nge-Laser:

Ilensi Yokugxila:Iguqula umsebe we-laser ube yindawo encane ukuze kusikwe ngokunembile.

Impumulo:Iziqondiso zisiza amagesi (njengomoya-mpilo noma i-nitrogen) endaweni yokusika ukuze kuthuthukiswe ukusebenza kahle kokusika, kuthuthukiswe ikhwalithi yokusika, futhi kuvinjelwe ukwakheka kwemfucumfucu.

Inzwa Yokuphakama:Igcina ibanga elilinganayo phakathi kwekhanda lokusika kanye nezinto zokwakha, iqinisekisa ikhwalithi yokusika efanayo.

Isilawuli se-CNC:

Uhlelo Lokulawula Izinombolo Zekhompyutha (CNC): Luphatha imisebenzi yomshini, okuhlanganisa ukunyakaza, amandla e-laser, kanye nesivinini sokusika. Luhumusha ifayela lokuklama (ngokuvamile nge-DXF noma amafomethi afanayo) futhi lulihumushele ekunyakazeni okunembile kanye nezenzo ze-laser.

Ithebula Lokusebenza:

Ithebula Le-Shuttle:Itafula le-shuttle, elibizwa nangokuthi i-pallet changer, lakhiwe ngendlela yokudlulisa ukuze lithuthwe ngezindlela ezimbili. Ukuze kube lula ukulayishwa nokuthululwa kwezinto ezinganciphisa noma ziqede isikhathi sokungasebenzi futhi zihlangabezane nokusika kwezinto ezithile, saklama osayizi abahlukahlukene ukuze bavumelane nosayizi ngamunye wemishini yokusika i-laser ye-MimoWork.

Umbhede We-Laser We-Honeycomb:Ihlinzeka ngendawo eyisicaba nezinzile enendawo encane yokuxhumana, inciphisa ukubonakaliswa kwangemuva futhi ivumela ukusikeka okuhlanzekile. Umbhede wezinyosi we-laser uvumela umoya opholile wokushisa, uthuli, kanye nentuthu ngesikhathi senqubo yokusika nge-laser.

Ithebula Lokugoqa Ummese:Ngokuyinhloko yenzelwe ukusika izinto ezijiyile lapho ungathanda ukugwema ukuphinda ubuye nge-laser. Amabha aqondile nawo avumela ukugeleza kokukhipha okungcono kakhulu ngenkathi usika. Ama-lamella angabekwa ngawodwana, ngenxa yalokho, itafula le-laser lingalungiswa ngokuya ngesicelo ngasinye.

Ithebula Lokuhambisa:Itafula lokuhambisa lenziwe ngeiwebhu yensimbi engagqwaliokufanelekelayoizinto ezincane neziguquguqukayo ezifanaifilimu,indwangufuthiisikhumba.Ngohlelo lokuhambisa, ukusika nge-laser okungapheli sekuyinto engenzeka. Ukusebenza kahle kwezinhlelo ze-laser ze-MimoWork kungandiswa kakhulu.

Ithebula Legridi Lokusika Le-Acrylic:Kubandakanya itafula lokusika nge-laser elinegridi, igridi ekhethekile yokuqopha nge-laser ivimbela ukubuyisa emuva. Ngakho-ke ilungele ukusika ama-acrylic, ama-laminate, noma amafilimu epulasitiki anezingxenye ezincane kune-100 mm, njengoba lezi zihlala zisesimweni esithe tyaba ngemva kokusikwa.

Ithebula Lokusebenza Lephini:Iqukethe izikhonkwane eziningi ezilungisekayo ezingahlelwa ngezindlela ezahlukene ukuze zisekele izinto ezisikwayo. Lo mklamo unciphisa ukuxhumana phakathi kwezinto kanye nendawo yokusebenza, okunikeza izinzuzo eziningana zokusika nokuqopha nge-laser.

Uhlelo Lokunyakaza:

Ama-Stepper Motors noma ama-Servo Motors:Shayela ukunyakaza kwe-X, Y, futhi ngezinye izikhathi ukunyakaza kwe-Z-axis kwekhanda elisikayo. Ama-Servo motors ngokuvamile anembe kakhulu futhi ashesha kunezinjini ze-stepper.

Iziqondiso Eziqondile kanye Nezitimela:Qinisekisa ukunyakaza okubushelelezi nokunembile kwekhanda elisikayo. Zibalulekile ekugcineni ukunemba nokuvumelana kokusika isikhathi eside.

Uhlelo Lokupholisa:

Isishisi Samanzi: Igcina ishubhu ye-laser nezinye izingxenye zisezingeni lokushisa elifanele ukuvimbela ukushisa ngokweqile nokugcina ukusebenza okulinganayo.

Usizo Lomoya:Ifutha umoya nge-nozzle ukuze isuse udoti, inciphise izindawo ezithintekile ekushiseni, futhi ithuthukise ikhwalithi yokusika.

Uhlelo Lokukhipha Umoya:

Susa umusi, intuthu, kanye nezinhlayiya ezikhiqizwe ngesikhathi senqubo yokusika, uqinisekise indawo yokusebenza ehlanzekile nephephile. Umoya ofanele uyadingeka ekugcineni ikhwalithi yomoya nokuvikela umqhubi kanye nomshini.

Iphaneli yokulawula:

Inikeza isikhombimsebenzisi sabasebenzisi sokufaka izilungiselelo, ukuqapha isimo somshini, nokulawula inqubo yokusika. Ingafaka isibonisi sesikrini sokuthinta, inkinobho yokuma ephuthumayo, kanye nezinketho zokulawula ngesandla zokulungisa okuhle.

Izici Zokuphepha:

Idivayisi Yezimbobo:Vikela abaqhubi ekuvezweni yi-laser kanye nemfucumfucu engaba khona. Izivalo zivame ukukhiywa ukuze zivale i-laser uma ivuliwe ngesikhathi sokusebenza.

Inkinobho Yokuma Eziphuthumayo:Ivumela ukuvala umshini ngokushesha uma kwenzeka isimo esiphuthumayo, okuqinisekisa ukuphepha komqhubi.

Izinzwa Zokuphepha Ze-Laser:Thola noma yiziphi izinto ezingavamile noma izimo ezingaphephile, okubangela ukuvala okuzenzakalelayo noma izexwayiso.

Isofthiwe:

Isofthiwe Yokusika Nge-Laser: I-MimoCUT, isofthiwe yokusika nge-laser, yenzelwe ukwenza umsebenzi wakho wokusika ube lula. Ukulayisha amafayela akho evektha e-laser cut. I-MimoCUT izohumusha imigqa, amaphuzu, ama-curve, kanye nezimo ezichaziwe zibe ulimi lokuhlela olungabonwa yisofthiwe yokusika nge-laser, futhi iqondise umshini we-laser ukuthi usebenze.

Isofthiwe ye-Auto-Nest:I-MimoNEST, isofthiwe yokusika izidleke nge-laser isiza abenzi bezinto ukunciphisa izindleko zezinto futhi ithuthukisa izinga lokusetshenziswa kwezinto ngokusebenzisa ama-algorithms athuthukile ahlaziya ukuhlukahluka kwezingxenye. Ngamagama alula, ingabeka amafayela okusika nge-laser ezintweni kahle. Isofthiwe yethu yokusika izidleke yokusika nge-laser ingasetshenziswa ukusika izinto eziningi njengezakhiwo ezifanele.

Isofthiwe Yokuqaphela Ikhamera:I-MimoWork iyathuthuka Uhlelo Lokubeka Ikhamera Ye-CCD Nge-Laser okungabona futhi kutholakale izindawo zesici ukuze kukusize wonge isikhathi futhi wandise ukunemba kokusika nge-laser ngesikhathi esifanayo. Ikhamera ye-CCD ifakwe eceleni kwekhanda le-laser ukuze iseshe umsebenzi wokusebenza usebenzisa izimpawu zokubhalisa ekuqaleni kwenqubo yokusika. Ngale ndlela, izimpawu eziphrintiwe, ezilukiwe nezifekethisiwe kanye nezinye izinkomba ezibonisa umehluko omkhulu zingaskenwa ngokubonakalayo ukuze ikhamera yokusika nge-laser ikwazi ukwazi ukuthi indawo yangempela kanye nobukhulu bezingcezu zomsebenzi bukuphi, kufezwe umklamo wokusika nge-laser wephethini enembile.

Isofthiwe Yokuphrojektha:Ngu- Isofthiwe ye-Mimo Projection, uhlaka kanye nendawo yezinto ezizosikwa kuzobonakala etafuleni lokusebenza, okusiza ukulinganisa indawo enembile yekhwalithi ephezulu yokusika nge-laser. NgokuvamileIzicathulo noma Izicathuloukusika nge-laser kusebenzisa idivayisi yokuphrojektha. Njengokuthi Isikhumba sangempela izicathulo, isikhumba se-pu izicathulo, ama-upper okuluka, ama-sneakers.

Isofthiwe Yesibonelo:Ngokusebenzisa ikhamera ye-HD noma isithwebuli sedijithali, I-MimoPROTOTYPE ibona ngokuzenzakalelayo izinhlaka kanye nemicibisholo yokuthunga yento ngayinye futhi ikhiqize amafayela okuklama ongawangenisa ngqo kwisofthiwe yakho ye-CAD. Uma kuqhathaniswa nephuzu lokulinganisa lendabuko ngesandla, ukusebenza kahle kwesofthiwe yesibonelo kuphakeme kaningana. Udinga nje ukubeka amasampula okusika etafuleni lokusebenza.

Amagesi Okusiza:

Umoya-mpilo:Kuthuthukisa isivinini sokusika kanye nekhwalithi yezinsimbi ngokwenza kube lula ukusabela kwe-exothermic, okwengeza ukushisa enkambisweni yokusika.

I-nitrogen:Isetshenziselwa ukusika okungezona izinsimbi kanye nezinye izinsimbi ukuze kufezwe ukusikeka okuhlanzekile ngaphandle kokungcola.

Umoya Ocindezelwe:Isetshenziselwa ukusika okungezona izinsimbi ukuze kuqhunyiswe izinto ezincibilikisiwe futhi kuvinjelwe ukusha.

Lezi zingxenye zisebenza ngokuvumelana ukuqinisekisa ukusebenza okunembile, okusebenzayo, nokuphephile kokusika nge-laser kuzo zonke izinto ezahlukahlukene, okwenza imishini yokusika nge-laser ibe ngamathuluzi ahlukahlukene ekukhiqizeni nasekukhiqizeni kwesimanje.

Imisebenzi eminingi kanye nokuguquguquka kwesikhiphi se-laser sekhamera kusiza ukusika ilebula elukiwe, isitikha, kanye nefilimu yokunamathisela ezingeni eliphakeme ngokusebenza kahle okuphezulu kanye nokunemba okuphezulu. Amaphethini okuphrinta nokuthunga esiqeshini kanye nelebula elukiwe kudingeka asikwe ngokunembile...

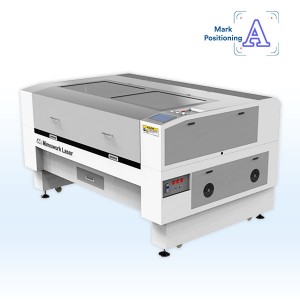

Ukuze kuhlangatshezwane nezidingo zebhizinisi elincane, kanye nomklamo owenziwe ngokwezifiso, i-MimoWork yaklama umshini wokusika i-laser omncane onosayizi wedeskithophu ongu-600mm * 400mm. Umshini wokusika i-laser wekhamera ufanelekela ukusika i-patch, ukufekethisa, isitikha, ilebula, kanye ne-applique esetshenziswa ezingutsheni nasezintweni...

I-contour laser cutter 90, ebizwa nangokuthi i-CCD laser cutter iza nosayizi womshini ongu-900mm * 600mm kanye nomklamo we-laser ovalwe ngokuphelele ukuqinisekisa ukuphepha okuphelele, ikakhulukazi kwabaqalayo. Njengoba i-CCD Camera ifakiwe eceleni kwekhanda le-laser, noma iyiphi iphethini nesimo...

Yakhelwe Ngokukhethekile Imboni Yezimpawu Nefenisha, Sebenzisa Amandla Obuchwepheshe Bekhamera Ethuthukisiwe ye-CCD ukuze Unqume Ngokuphelele I-Acrylic Ephrintiwe Enephethini. Nge-Ball Screw Transmission kanye Nezinketho Ze-Servo Motor Ezine-Precision Ephakeme, Zicwilise Ngokuqondile Okungalingani kanye...

Thola i-Curtain-Edge Fusion yoBuciko nobuchwepheshe nge-Mimowork's Printed Wood Laser Cutter. Vula Umhlaba Wamathuba Njengoba Usika Futhi Uqopha Ngomthungo Izinkuni Nezinto Ezidalwe Ngokhuni Eziprintiwe. Yenzelwe Imboni Yezimpawu Nefenisha, i-Laser Cutter Yethu Isebenzisa i-Advanced CCD...

Ifakwe ikhamera ye-HD yobuchwepheshe obuphezulu ebekwe phezulu, ibona kalula ama-contour futhi idlulisele idatha yamaphethini ngqo emshinini wokusika indwangu. Valelisa izindlela zokusika eziyinkimbinkimbi, njengoba lobu buchwepheshe bunikeza ikhambi elilula nelinembile kakhulu le-lace kanye...

Sethula uMshini Wezingubo Zezemidlalo Osikiwe Nge-Laser (160L) – ikhambi eliphelele lokusika i-sublimation ngedayi. Ngekhamera yayo entsha ye-HD, lo mshini ungabona futhi udlulisele idatha yephethini ngokuqondile emshinini wokusika iphethini yendwangu. Iphakheji yethu yesofthiwe inikeza izinketho eziningi.

Sethula i-Sublimation Polyester Laser Cutter (180L) eshintsha umdlalo – ikhambi eliphelele lokusika izindwangu ze-sublimation ngokunemba okungenakuqhathaniswa. Ngosayizi wetafula elisebenzayo omkhulu ongu-1800mm*1300mm, lo msiki wenzelwe ngqo ukucubungula i-polyester ephrintiwe...

Ngena ezweni eliphephile, elihlanzekile, nelinembe kakhulu lokusika indwangu ye-sublimation nge-Laser Cut Sportswear Machine (Efakwe Ngokugcwele). Isakhiwo sayo esivalekile sinikeza izinzuzo ezintathu: ukuphepha okuthuthukisiwe komqhubi, ukulawula uthuli okuphezulu, kanye nokungcono...

Ukuze kuhlangatshezwane nezidingo zokusika zendwangu yokugoqa enkulu nebanzi, i-MimoWork yaklama i-laser cutter ye-sublimation yefomethi ebanzi kakhulu ene-CCD Camera ukusiza ukusika izindwangu eziphrintiwe njengezibhengezo, amafulegi e-teardrop, izimpawu, isibonisi sombukiso, isibonisi sombukiso, njll. Indawo yokusebenza engu-3200mm * 1400mm...

I-Contour Laser Cutter 160 ifakwe ikhamera ye-CCD efanele ukucubungula izinhlamvu ze-twill ezinembile kakhulu, izinombolo, amalebula, izesekeli zezingubo, izindwangu zasekhaya. Umshini wokusika nge-laser wekhamera usebenzisa isofthiwe yekhamera ukuze ubone izindawo zezici futhi wenze ukusika kwephethini okunembile...

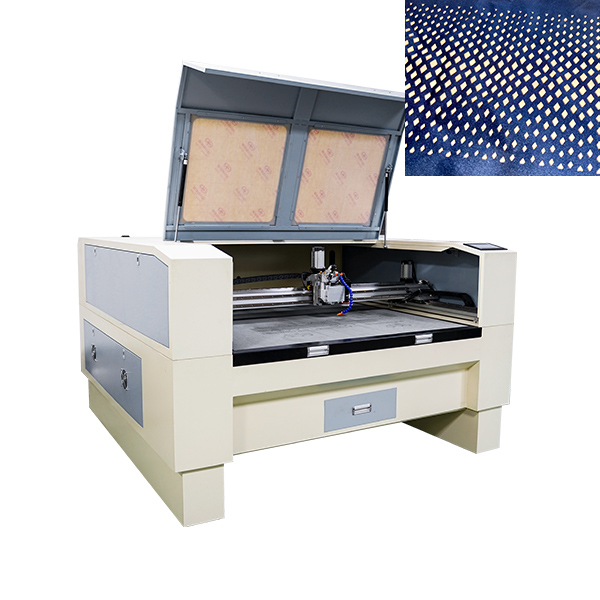

▷ Umshini Wokusika We-Laser Oyisicaba (Owenziwe Ngokwezifiso)

Usayizi womshini omncane usindisa isikhala kakhulu futhi ungamukela izinto ezidlula ububanzi bokusika ngomklamo wokungena ngezindlela ezimbili. I-Mimowork's Flatbed Laser Engraver 100 yenzelwe kakhulu ukuqopha nokusika izinto eziqinile nezinto eziguquguqukayo, njengokhuni, i-acrylic, iphepha, izindwangu...

Umqophi we-Laser wokhuni ongenziwa ngokwezifiso zakho kanye nesabelomali sakho. I-MimoWork's Flatbed Laser Cutter 130 yenzelwe kakhulu ukuqopha nokusika ukhuni (i-plywood, i-MDF), ingasetshenziswa nakwi-acrylic nezinye izinto. Ukuqopha nge-laser okuguquguqukayo kusiza ukufeza ukhuni oluqondene nawe...

Umshini wokuqopha we-Acrylic Laser ongenziwa ngokwezifiso zakho kanye nesabelomali sakho. I-Mimowork's Flatbed Laser Cutter 130 yenzelwe kakhulu ukuqopha nokusika i-acrylic (plexiglass/PMMA), ingasetshenziswa nasezingodweni nakwezinye izinto. Ukuqopha kwe-laser okuguquguqukayo kusiza...

Ilungele ukusika amashidi amakhulu nokhuni olujiyile ukuze kuhlangatshezwane nezikhangiso ezahlukahlukene kanye nezicelo zezimboni. Itafula lokusika nge-laser elingu-1300mm * 2500mm lenzelwe ukufinyelela ngezindlela ezine. Njengoba liphawulwa ngesivinini esikhulu, umshini wethu wokusika nge-laser wokhuni we-CO2 ungafinyelela isivinini sokusika esingu-36,000mm...

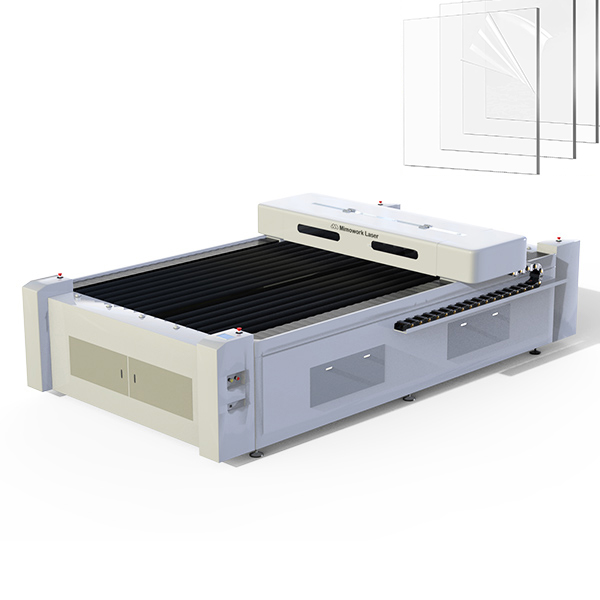

Ilungele ukusika nge-laser amashidi amakhulu kanye nama-acrylic aqinile ukuze kuhlangatshezwane nokukhangisa okuhlukahlukene kanye nezicelo zezimboni. Ithebula lokusika nge-laser elingu-1300mm * 2500mm lenzelwe ukufinyelela ngezindlela ezine. Amashidi e-acrylic okusika nge-laser asetshenziswa kabanzi embonini yokukhanyisa neyezentengiselwano, emkhakheni wokwakha...

Umshini we-laser omncane noncane uthatha isikhala esincane futhi kulula ukuwusebenzisa. Ukusika nokuqopha nge-laser okuguquguqukayo kuhambisana nalezi zidingo zemakethe ezenziwe ngokwezifiso, ezivelele emkhakheni wezandla zephepha. Ukusika iphepha okuyinkimbinkimbi kumakhadi esimemo, amakhadi okubingelela, izincwajana, ukwenza i-scrapbooking, kanye namakhadi ebhizinisi...

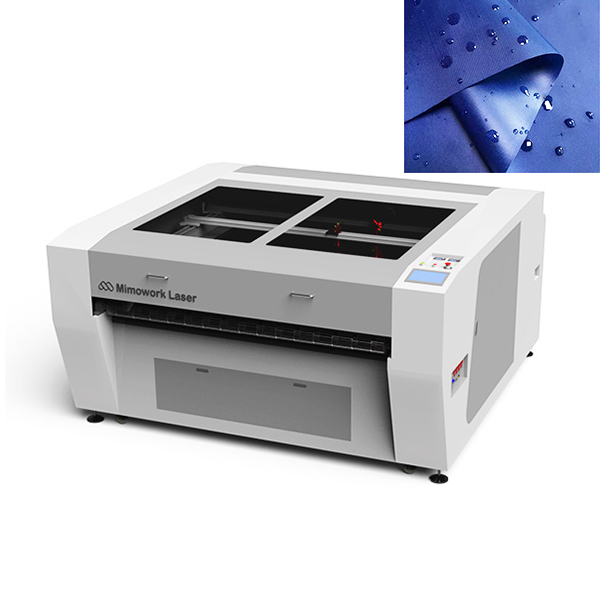

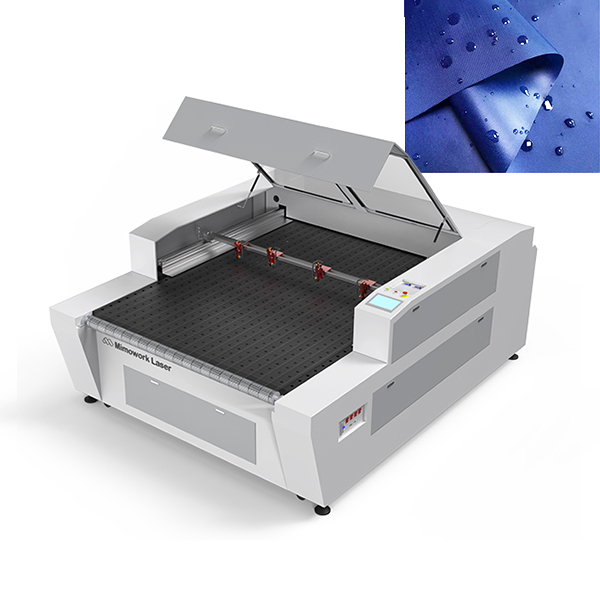

Ukulingana nosayizi wezingubo nezingubo ezijwayelekile, umshini wokusika i-laser wendwangu unetafula lokusebenza elingu-1600mm * 1000mm. Indwangu ethambile yokugoqa ifaneleka kakhulu ekusikeni nge-laser. Ngaphandle kwalokho, isikhumba, ifilimu, i-felt, i-denim nezinye izingcezu zonke zingasikwa nge-laser ngenxa yetafula lokusebenza lokuzikhethela...

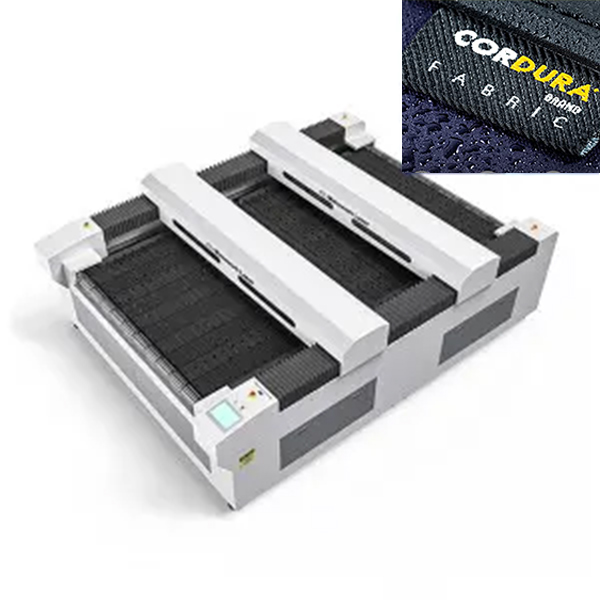

Ngokusekelwe emandleni aphezulu kanye nobuningi be-Cordura, ukusika nge-laser kuyindlela yokucubungula esebenza kahle kakhulu ikakhulukazi ukukhiqizwa kwezimboni ze-PPE kanye nemishini yezempi. Umshini wokusika nge-laser wendwangu yezimboni ufakwe indawo enkulu yokusebenza ukuze uhlangabezane nefomethi enkulu yokusika efana ne-Cordura...

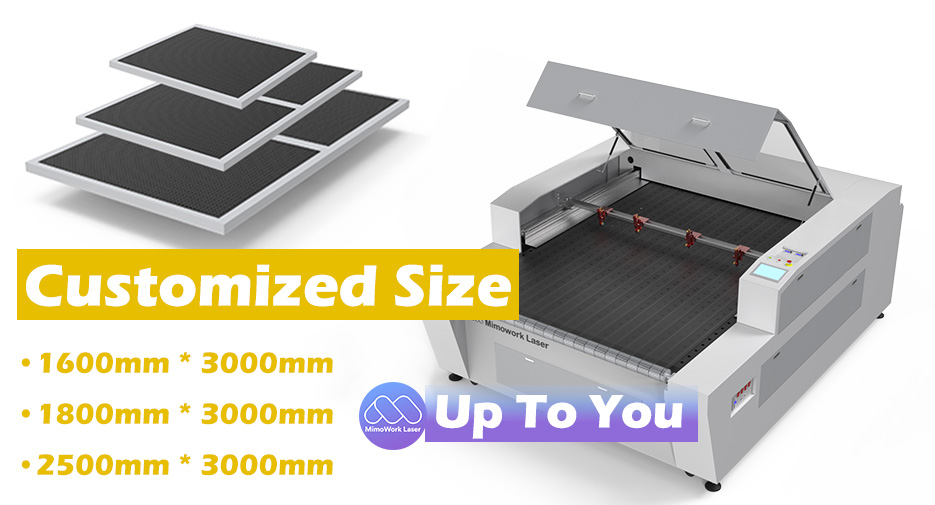

Ukuze kuhlangatshezwane nezinhlobo eziningi zezimfuneko zokusika zendwangu ngobukhulu obuhlukene, i-MimoWork yandisa umshini wokusika nge-laser ube ngu-1800mm * 1000mm. Kuhlanganiswe netafula lokuhambisa, indwangu yokugoqa kanye nesikhumba kungavunyelwa ukudlulisa kanye nokusika nge-laser kwemfashini kanye nezindwangu ngaphandle kokuphazamiseka. Ngaphezu kwalokho, amakhanda e-laser amaningi...

Umshini Wokusika We-Laser Enkulu Wefomethi Enkulu wenzelwe izindwangu nezindwangu ezinde kakhulu. Njengoba unetafula lokusebenza elingamamitha ayi-10 ubude kanye netafula elibanzi elingamamitha ayi-1.5, umsiki we-laser omkhulu wefomethi ufanelekela amashidi amaningi endwangu nama-roll afana netende, i-parachute, i-kitesurfing, ikhaphethi yezindiza, i-pelmet yokukhangisa kanye nezimpawu, indwangu yokuhamba ngomkhumbi nokunye...

Umshini wokusika nge-laser we-CO2 ufakwe uhlelo lwephrojektha olunomsebenzi wokubeka indawo onembile. Ukubuka kuqala kwento yokusebenza ezosikwa noma eqoshiwe kukusiza ukuthi ubeke izinto endaweni efanele, okwenza ukusika ngemuva kwe-laser kanye nokuqoshwa nge-laser kuhambe kahle futhi ngokunemba okuphezulu...

Umshini we-Galvo Laser (Sika & Uqophe Futhi Ubhoboze)

I-MimoWork Galvo Laser Marker ingumshini onezinjongo eziningi. Ukuqoshwa kwe-laser ephepheni, iphepha lokusika i-laser elenziwe ngokwezifiso kanye nokubhoboza iphepha konke kungaqedwa ngomshini we-galvo laser. Ugongolo lwe-laser lwe-Galvo olunokunemba okuphezulu, ukuguquguquka, kanye nesivinini sombani kudala...

Ukukhanya kwe-laser okundizayo kusuka ekhoneni lelensi eliguqukayo kungasebenza ngokushesha ngaphakathi kwesikali esichaziwe. Ungalungisa ukuphakama kwekhanda le-laser ukuze kulingane nosayizi wezinto ezicutshunguliwe. Ishubhu le-laser lensimbi le-RF linikeza ukumaka okunembile okuphezulu nge-laser spot encane kuya ku-0.15mm, okulungele ukuqoshwa kwe-laser yephethini eyinkimbinkimbi esikhumbeni...

Umshini we-laser we-Fly-Galvo uhlonyiswe nge-CO2 laser tube kuphela kodwa ungahlinzeka kokubili ukubhoboza kwe-laser yendwangu kanye nokusika kwe-laser kwezingubo kanye nezindwangu zezimboni. Ngetafula lokusebenza elingu-1600mm * 1000mm, umshini we-laser wendwangu onezimbobo ungathwala izindwangu eziningi zamafomethi ahlukene, ufeze izimbobo zokusika ze-laser ezihambisanayo...

I-GALVO Laser Engraver 80 enomklamo ovalwe ngokuphelele ngokuqinisekile iyisinqumo sakho esifanele sokuqopha nokumaka nge-laser yezimboni. Ngenxa yombono wayo omkhulu we-GALVO ongu-800mm * 800mm, ilungele ukuqopha, ukumaka, ukusika, kanye nokubhoboza nge-laser esikhumbeni, ekhadini lephepha, ku-vinyl yokudlulisa ukushisa, noma kunoma yiziphi ezinye izingcezu ezinkulu...

Umqophi we-laser onefomethi enkulu ungowocwaningo nokuthuthukiswa kwezinto ezinkulu zokuqopha nge-laser kanye nokumaka nge-laser. Ngohlelo lokuhambisa, umqophi we-laser we-galvo angaqopha futhi amake izindwangu ezigoqekayo (izindwangu). Ungawubheka njengomshini wokuqopha nge-laser yendwangu, umshini wokuqopha nge-laser yekhaphethi, umqophi we-laser we-denim...

Isabelomali

Noma ngabe yimiphi imishini okhetha ukuyithenga, izindleko ezifaka phakathi intengo yomshini, izindleko zokuthumela, ukufakwa, kanye nezindleko zangemva kokulungiswa zihlala ziyizinto ozicabangela kuqala. Esigabeni sokuqala sokuthenga, unganquma izidingo zokusika ezibaluleke kakhulu zomkhiqizo wakho ngaphakathi komkhawulo othile wesabelomali. Thola ukucushwa kwe-laser kanye nezinketho zomshini we-laser ezihambisana nemisebenzi kanye nesabelomali. Ngaphandle kwalokho, udinga ukucabangela izindleko zokufaka nezokusebenza, njengokuthi ngabe kunezimali zokuqeqeshwa ezengeziwe, ukuthi uqasha abasebenzi, njll. Lokho kukusiza ukuthi ukhethe umhlinzeki wemishini ye-laser ofanele kanye nezinhlobo zomshini ngaphakathi kwesabelomali.

Amanani omshini wokusika nge-laser ayahlukahluka kuye ngezinhlobo zomshini, ukucushwa, kanye nezinketho. Sitshele izidingo zakho kanye nesabelomali sakho, futhi uchwepheshe wethu we-laser uzoncoma umshini wokusika nge-laser ongakhetha kuwo.⇨I-MimoWork Laser

Umthombo We-Laser

Uma utshala imali emshinini wokusika nge-laser, udinga ukwazi ukuthi yimuphi umthombo we-laser okwazi ukusika izinto zakho futhi ufinyelele umphumela wokusika olindelekile. Kunezinhlobo ezimbili ezivamile ze-laser:i-fiber laser kanye ne-CO2 laser. I-laser yefayibha isebenza kahle ekusikeni nasekumakeni ezintweni zensimbi neze-alloy. I-laser ye-CO2 ikhethekile ekusikeni nasekuqopheni izinto ezingezona ezensimbi. Ngenxa yokusetshenziswa kabanzi kwama-laser e-CO2 kusukela ezingeni lomkhakha kuya ezingeni lokusetshenziswa kwansuku zonke ekhaya, iyakwazi futhi kulula ukuyisebenzisa. Xoxa ngezinto zakho nochwepheshe wethu we-laser, bese unquma umthombo we-laser ofanele.

Ukucushwa Komshini

Ngemva kokunquma umthombo we-laser, udinga ukuxoxa ngezidingo zakho ezithile zezinto zokusika ezifana nesivinini sokusika, ivolumu yokukhiqiza, ukunemba kokusika, kanye nezakhiwo zezinto ezibonakalayo nochwepheshe wethu we-laser. Lokho kunquma ukuthi yiziphi izilungiselelo ze-laser nezinketho ezifanele futhi ezingafinyelela umphumela omuhle wokusika. Isibonelo, uma unezidingo eziphezulu zomkhiqizo wansuku zonke, isivinini sokusika kanye nokusebenza kahle kuzoba yinto yokuqala oyicabangelayo. Amakhanda amaningi e-laser, izinhlelo zokondla ngokuzenzakalela kanye nezokuhambisa, kanye nesofthiwe ethile yokwenza izidleke ngokuzenzakalela ingathuthukisa ukusebenza kahle kokukhiqiza kwakho. Uma uthanda kakhulu ukunemba kokusika, mhlawumbe i-servo motor kanye ne-metal laser tube zikufanele kakhulu.

Indawo Yokusebenza

Indawo yokusebenza iyisici esibalulekile ekukhetheni imishini. Ngokuvamile, abahlinzeki bemishini ye-laser babuza ngolwazi lwakho lwezinto ezibonakalayo, ikakhulukazi usayizi wezinto ezibonakalayo, ukujiya, kanye nosayizi wephethini. Lokho kunquma ifomethi yetafula lokusebenza. Futhi uchwepheshe we-laser uzohlaziya usayizi wephethini yakho kanye nokwakheka kwesimo ngokuxoxa nawe, ukuthola imodi yokudla efanele ehambisana netafula lokusebenza. Sinosayizi ojwayelekile wokusebenza womshini wokusika i-laser, ongahlangabezana nezidingo zamakhasimende amaningi, kodwa uma unezidingo ezikhethekile zezinto ezibonakalayo kanye nokusika, sicela usazise, uchwepheshe wethu we-laser uchwepheshe futhi unolwazi lokusingatha inkinga yakho.

Ubuciko

Umshini wakho

| Usayizi Wokusebenza Komshini (W * L) |

| •600mm * 400mm |

| •1000mm * 600mm |

| •1300mm * 900mm |

| •1300mm * 2500mm |

| •1600mm * 1000mm |

| •1600mm * 1200mm |

| •1600mm * 3000mm |

| •1600mm * 10000mm |

| •1800mm * 1400mm |

| •2500mm * 3000mm |

| •3200mm * 1400mm |

Uma Unezidingo Ezikhethekile Zosayizi Womshini, Khuluma Nathi!

Umkhiqizi Womshini

Kulungile, usuwazi ulwazi lwakho lwezinto ezibonakalayo, izidingo zokusika, kanye nezinhlobo zemishini eyisisekelo, isinyathelo esilandelayo osidingayo ukuze useshe umenzi wemishini yokusika nge-laser othembekile. Ungasesha ku-Google, naku-YouTube, noma uthintane nabangani bakho noma ozakwethu, noma ngabe yikuphi, ukuthembeka nokuba yiqiniso kwabahlinzeki bemishini kuhlala kubaluleke kakhulu. Zama ukubathumelela i-imeyili, noma uxoxe nochwepheshe wabo we-laser ku-WhatsApp, ukuze ufunde kabanzi mayelana nokukhiqizwa komshini, ukuthi ifektri ikuphi, ukuthi ungaqeqesha kanjani futhi uqondise kanjani ngemva kokuthola umshini, nokunye okunjalo. Amanye amakhasimende ake a-oda umshini ezimbonini ezincane noma ezisekelweni zangaphandle ngenxa yentengo ephansi, nokho, uma umshini unezinkinga ezithile, awusoze uthole usizo nokusekelwa, okuzobambezela ukukhiqizwa kwakho futhi kuchithe isikhathi.

I-MimoWork Laser Ithi: Sihlala sibeka izidingo zeklayenti kanye nolwazi lokusebenzisa kuqala. Okutholayo akugcini nje ngokuba umshini we-laser omuhle futhi oqinile, kodwa futhi nesethi yesevisi ephelele kanye nokusekelwa kusukela ekufakweni, ekuqeqeshweni kuya ekusebenzeni.

① Thola Umkhiqizi Othembekile

Usesho lwe-Google ne-YouTube, noma vakashela ireferensi yendawo

② Bheka iwebhusayithi yayo noma i-YouTube

Hlola izinhlobo zemishini kanye nolwazi lwenkampani

③ Xhumana nochwepheshe we-laser

Thumela i-imeyili noma uxoxe nge-WhatsApp

⑥ Faka i-oda

Nquma isikhathi sokukhokha

⑤ Nquma Ezokuthutha

ukuthunyelwa noma ukuthunyelwa ngendiza

④ Umhlangano Oku-inthanethi

Xoxani ngokulungiswa komshini we-laser ofanele kakhulu

Mayelana Nokubonisana Nomhlangano

> Yiluphi ulwazi okudingeka ulunikeze?

> Ulwazi lwethu lokuxhumana

UKUSEBENZA

7. Ungayisebenzisa Kanjani Umshini Wokusika Nge-Laser?

Umshini Wokusika I-Laser uwumshini ohlakaniphile nozenzakalelayo, ngokusekelwa kohlelo lwe-CNC kanye nesofthiwe yokusika i-laser, umshini we-laser ungabhekana nezithombe eziyinkimbinkimbi futhi uhlele indlela yokusika efanele ngokuzenzakalelayo. Udinga nje ukungenisa ifayela lokusika ohlelweni lwe-laser, ukhethe noma usethe amapharamitha okusika i-laser njengejubane namandla, bese ucindezela inkinobho yokuqala. Umsiki we-laser uzoqeda yonke inqubo yokusika. Ngenxa yomphetho ophelele onomphetho obushelelezi kanye nobuso obuhlanzekile, awudingi ukusika noma ukupholisha izingcezu eziqediwe. Inqubo yokusika i-laser iyashesha futhi ukusebenza kulula futhi kunobungane kwabaqalayo.

▶ Isibonelo 1: Indwangu Yokusika I-Laser Roll

Isinyathelo 1. Beka i-Roll Fabric ku-Auto-Feeder

Lungisa Indwangu:Beka indwangu yokugoqa ohlelweni lokuphakela oluzenzakalelayo, gcina indwangu ithambile futhi imiphetho icocekile, bese uqala i-auto feeder, beka indwangu yokugoqa etafuleni lokuguqula.

Umshini We-Laser:Khetha umshini wokusika indwangu nge-laser one-feeder ezenzakalelayo kanye netafula lokuhambisa. Indawo yokusebenza komshini idinga ukufana nefomethi yendwangu.

▶

Isinyathelo 2. Ngenisa Ifayela Lokusika bese Usetha Amapharamitha E-Laser

Ifayela Lokuklama:Ngenisa ifayela lokusika kusofthiwe yokusika ye-laser.

Setha amapharamitha:Ngokuvamile, udinga ukusetha amandla e-laser kanye nesivinini se-laser ngokuya ngobukhulu bezinto, ubuningi, kanye nezidingo zokunemba kokusika. Izinto ezincane zidinga amandla aphansi, ungahlola isivinini se-laser ukuthola umphumela omuhle wokusika.

▶

Isinyathelo 3. Qala Indwangu Yokusika Nge-Laser

Ukusikwa kwe-Laser:Iyatholakala kumakhanda amaningi okusika nge-laser, ungakhetha amakhanda amabili e-laser ku-gantry eyodwa, noma amakhanda amabili e-laser ku-gantry ezimbili ezizimele. Lokho kuhlukile ekukhiqizeni kokusika nge-laser. Udinga ukuxoxa nochwepheshe wethu we-laser mayelana nephethini yakho yokusika.

▶ Isibonelo 2: Ukusikwa Kwe-Laser Okuphrintiwe Nge-Acrylic

Isinyathelo 1. Beka ishidi le-Acrylic etafuleni lokusebenza

Beka Izinto:Beka i-acrylic ephrintiwe etafuleni lokusebenza, ukuze sinqume i-acrylic nge-laser, sisebenzise itafula lokusika umcu wommese elingavimbela ukuthi izinto zingashi.

Umshini We-Laser:Siphakamisa ukusebenzisa i-acrylic laser engraver 13090 noma i-laser cutter enkulu 130250 ukusika i-acrylic. Ngenxa yephethini ephrintiwe, kudingeka ikhamera ye-CCD ukuqinisekisa ukusika okunembile.

▶

Isinyathelo 2. Ngenisa Ifayela Lokusika bese Usetha Amapharamitha E-Laser

Ifayela Lokuklama:Ngenisa ifayela lokusika kusofthiwe yokubona ikhamera.

Setha amapharamitha:INgokuvamile, udinga ukusetha amandla e-laser kanye nesivinini se-laser ngokuya ngobukhulu bezinto, ubuningi, kanye nezidingo zokunemba kokusika. Izinto ezincane zidinga amandla aphansi, ungahlola isivinini se-laser ukuthola umphumela omuhle wokusika.

▶

Isinyathelo 3. Ikhamera ye-CCD Iqaphela Iphethini Ephrintiwe

Ukuqashelwa Kwekhamera:Ezintweni eziphrintiwe njengendwangu ye-acrylic ephrintiwe noma ye-sublimation, uhlelo lokubona ikhamera luyadingeka ukuze lubone futhi lubeke iphethini, futhi lufundise ikhanda le-laser ukuthi lisike ngendlela efanele.

Isinyathelo 4. Qala ukusika nge-laser eceleni kwe-Pattern Contour

Ukusika nge-Laser:BNjengoba kubekwe endaweni yekhamera, ikhanda lokusika nge-laser lithola indawo efanele bese liqala ukusika ngokwendlela yephethini. Inqubo yonke yokusika iyenzeka ngokuzenzakalela futhi iyahambisana.

▶ Amathiphu Namaqhinga Lapho Usika Nge-Laser

✦ Ukukhetha Izinto:

Ukuze ufinyelele umphumela omuhle kakhulu wokusika nge-laser, udinga ukulungisa izinto kusengaphambili. Ukugcina izinto ziqondile futhi zihlanzekile kuyadingeka ukuze ubude bokusika nge-laser bufane ukuze umphumela wokusika uhlale umuhle. Kunezinhlobo eziningi ezahlukene zeizinto zokwakhaokungasikwa futhi kuqoshwe nge-laser, futhi izindlela zangaphambi kokwelashwa zihlukile, uma umusha kulokhu, ukukhuluma nochwepheshe wethu we-laser kuyisinqumo esingcono kakhulu.

✦Hlola Okokuqala:

Yenza isivivinyo se-laser usebenzisa izingcezu ezithile zamasampula, ngokusetha amandla ahlukene e-laser, isivinini se-laser ukuthola amapharamitha e-laser afanele, ukuze kuphume umphumela wokusika ophelele ohlangabezana nezidingo zakho.

✦Umoya opholile:

Izinto zokusika nge-laser zingase zikhiqize umusi kanye negesi engcolile, ngakho-ke kudingeka uhlelo lokungenisa umoya olusebenza kahle. Ngokuvamile sihlomisa ifeni yokukhipha umoya ngokuya ngendawo yokusebenza, usayizi womshini, kanye nezinto zokusika.

✦ Ukuphepha Kokukhiqiza

Kwezinto ezithile ezikhethekile njengezinto ezihlanganisiwe noma izinto zepulasitiki, siphakamisa ukuthi amakhasimende ahlomiseumshini wokukhipha intuthuyomshini wokusika nge-laser. Lokho kungenza indawo yokusebenza ihlanzeke futhi iphephe kakhudlwana.

✦ Thola i-Laser Focus:

Qinisekisa ukuthi umsebe we-laser ugxile kahle ebusweni bezinto ezibonakalayo. Ungasebenzisa izindlela ezilandelayo zokuhlola ukuthola ubude obufanele be-laser focal, bese ulungisa ibanga ukusuka ekhanda le-laser kuya ebusweni bezinto ezibonakalayo ngaphakathi kobubanzi obuthile obuzungeze ubude obuqondile, ukuze ufinyelele umphumela wokusika nokuqopha ofanele. Kukhona umehluko phakathi kokusika kwe-laser nokuqopha kwe-laser. Ukuze uthole imininingwane mayelana nendlela yokuthola ubude obufanele be-focal, sicela ubheke ividiyo >>

Ividiyo Yokufundisa: Ungayithola Kanjani I-Focus Efanele?

▶ Nakekela i-Water Chiller yakho

I-water chiller idinga ukusetshenziswa endaweni enomoya opholile futhi epholile. Futhi ithangi lamanzi lidinga ukuhlanzwa njalo futhi amanzi kufanele ashintshwe njalo ezinyangeni ezi-3. Ebusika, ukwengeza i-antifreeze ku-water chiller kuyadingeka ukuze kuvinjelwe ukubanda. Funda kabanzi mayelana nendlela yokugcina ukubanda kwamanzi ebusika, sicela ubheke ikhasi:Izindlela Zokusika I-Laser Ezingangeni Eqandeni Ebusika

▶ Hlanza i-Focus Lens kanye nezibuko

Uma usika futhi uqopha izinto nge-laser, kuzokhiqizwa umusi othile, udoti, kanye ne-resin bese kushiywa ezibukweni nakulensi. Imfucuza eqoqiwe ikhiqiza ukushisa okulimaza ilensi nezibuko, futhi inomthelela ekukhishweni kwamandla nge-laser. Ngakho-ke ukuhlanza ilensi nezibuko ezigxile kuyadingeka. Cwilisa i-swab yekotini emanzini noma ngotshwala ukuze usule ubuso belensi, khumbula ukungathinti ubuso ngezandla zakho. Kukhona umhlahlandlela wevidiyo ngalokho, hlola lokhu >>

▶ Gcina Itafula Lokusebenza Lihlanzekile

Ukugcina itafula lokusebenza lihlanzekile kubalulekile ukuze kuhlinzekwe indawo yokusebenza ehlanzekile neyisicaba yezinto zokwakha kanye nekhanda lokusika nge-laser. I-resin kanye nezinsalela azigcini nje ngokungcolisa izinto, kodwa futhi zithinta umphumela wokusika. Ngaphambi kokuhlanza itafula lokusebenza, udinga ukuvala umshini. Bese usebenzisa i-vacuum cleaner ukususa uthuli kanye nemfucumfucu esele etafuleni lokusebenza bese ushiya ebhokisini lokuqoqa imfucuza. Bese uhlanza itafula lokusebenza kanye nereyili ngethawula likakotini elimanziswe yi-cleaner. Ulinde itafula lokusebenza ukuthi lome, bese ufaka ugesi.

▶ Hlanza Ibhokisi Lokuqoqa Uthuli

Hlanza ibhokisi lokuqoqa uthuli nsuku zonke. Amanye ama-debris kanye nezinsalela ezikhiqizwa ngezinto zokusika nge-laser ziwela ebhokisini lokuqoqa uthuli. Udinga ukuhlanza ibhokisi izikhathi eziningana emini uma umthamo wokukhiqiza mkhulu.

• Qinisekisa njalo ukuthiizingidi zokuphephazisebenza kahle. Qinisekisa ukuthiinkinobho yokumisa ephuthumayo, isibani sesignalizisebenza kahle.

•Faka umshini ngaphansi kwesiqondiso sochwepheshe we-laser.Ungalokothi uvule umshini wakho wokusika nge-laser kuze kube yilapho usuhlanganiswe ngokuphelele futhi zonke izembozo sezisendaweni.

•Ungasebenzisi umshini wokusika nowokuqopha we-laser eduze kwanoma yimuphi umthombo wokushisa ongaba khona.Gcina njalo indawo ezungeze umshini wokusika ingenazo izinsalela, imfucuza, nezinto ezivuthayo.

• Ungazami ukulungisa umshini wokusika nge-laser wedwa -thola usizo lochwepheshekusuka kuchwepheshe we-laser.

•Sebenzisa izinto zokuphepha nge-laserEzinye izinto eziqoshiwe, ezimakwe, noma ezisikwe nge-laser zingakhiqiza umusi onobuthi futhi oqothulayo. Uma ungaqiniseki, sicela uxhumane nochwepheshe wakho we-laser.

•UNGALOKOTHI usebenzise uhlelo ngaphandle kokuqashwaQinisekisa ukuthi umshini we-laser usebenza ngaphansi kokuqondisa komuntu.

• AI-fire extinguisherKufanele Kufakwe Odongeni Eduze Komshini Wokusika I-Laser.

• Ngemva kokusika ezinye izinto zokuhambisa ukushisa, wenangidinga ama-tweezers noma amagilavu aqinile ukuze ngithathe indwangu.

• Kwezinye izinto ezifana nepulasitiki, ukusika nge-laser kungakhiqiza umusi nothuli oluningi olungavunyelwe indawo yakho yokusebenza. Bese kubaumshini wokukhipha intuthuyisinqumo sakho esingcono kakhulu, esingamunca futhi sihlanze imfucuza, siqinisekise ukuthi indawo yokusebenza ihlanzekile futhi iphephile.

•Izibuko zokuphepha ze-laserzinamalensi aklanywe ngokukhethekile anombala ukuze amunce ukukhanya kwe-laser futhi akuvimbele ukuthi kudlule emehlweni ogqokile. Izibuko kumele zihambisane nohlobo lwe-laser (kanye nobude besikhathi) obusebenzisayo. Zivame futhi ukuba nemibala ehlukene ngokuya ngobude besikhathi obumunca: okwesibhakabhaka noma oluhlaza okotshani kuma-diode lasers, okumpunga kuma-CO2 lasers, kanye noluhlaza okotshani kuma-fiber lasers.

Imibuzo Evame Ukubuzwa

• Malini umshini wokusika nge-laser?

Izisiki ze-laser ze-CO2 eziyisisekelo zisukela ngaphansi kuka-$2,000 kuya ngaphezu kuka-$200,000. Umehluko wentengo mkhulu kakhulu uma kukhulunywa ngokuhlelwa okuhlukile kwezisiki ze-laser ze-CO2. Ukuze uqonde izindleko zomshini we-laser, udinga ukucabanga okungaphezu kwentengo yokuqala. Kufanele futhi ucabangele izindleko eziphelele zokuba nomshini we-laser kukho konke ukuphila kwawo, ukuze uhlole kangcono ukuthi kufanelekile yini ukutshala imali engxenyeni yemishini ye-laser. Imininingwane mayelana namanani omshini wokusika we-laser ukuze uhlole ikhasi:Kubiza Malini Umshini We-Laser?

• Usebenza kanjani umshini wokusika nge-laser?

Ugongolo lwe-laser luqala emthonjeni we-laser, futhi luqondiswa futhi lugxilwe yizibuko kanye nelensi yokugxila kuya ekhanda le-laser, bese ludutshulwa ezintweni. Uhlelo lwe-CNC lulawula ukukhiqizwa kogongolo lwe-laser, amandla kanye nokushaya kwe-laser, kanye nendlela yokusika yekhanda le-laser. Uma luhlanganiswe nomshini womoya ovunguzayo, ifeni yokukhipha ugesi, idivayisi yokunyakaza kanye netafula lokusebenza, inqubo eyisisekelo yokusika i-laser ingaqedwa kahle.

• Yimuphi ugesi osetshenziswa emshinini wokusika nge-laser?

Kunezingxenye ezimbili ezidinga igesi: i-resonator kanye nekhanda lokusika nge-laser. Kwi-resonator, igesi ehlanganisa i-CO2 ehlanzekile kakhulu (ibanga lesi-5 noma ngaphezulu) iyadingeka ukukhiqiza umsebe we-laser. Kodwa ngokuvamile, awudingi ukufaka esikhundleni la magesi. Ekhanda lokusika, igesi elisiza nge-nitrogen noma i-oxygen liyadingeka ukusiza ukuvikela izinto ezizocutshungulwa nokuthuthukisa umsebe we-laser ukuze kufinyelelwe umphumela omuhle wokusika.

• Uyini Umehluko: Umsiki We-Laser Vs Umsiki We-Laser?

Mayelana ne-MimoWork Laser

I-Mimowork ingumkhiqizi we-laser ogxile emiphumeleni, oseShanghai naseDongguan China, oletha iminyaka engama-20 yobuchwepheshe obujulile bokusebenza ukukhiqiza izinhlelo ze-laser nokunikeza izixazululo eziphelele zokucubungula nokukhiqiza kuma-SME (amabhizinisi amancane naphakathi) ezimbonini eziningi ezahlukene.

Okuhlangenwe nakho kwethu okucebile kwezixazululo ze-laser zokucubungula izinto zensimbi nezingezona ezensimbi kugxile kakhulu emhlabeni jikelele.isikhangiso, izimoto kanye nezindiza, insimbi, izinhlelo zokusebenza zokufaka umbala odayiwe, indwangu nezindwanguizimboni.

Esikhundleni sokunikeza ikhambi elingaqinisekile elidinga ukuthengwa kubakhiqizi abangafaneleki, i-MimoWork ilawula yonke ingxenye yochungechunge lokukhiqiza ukuqinisekisa ukuthi imikhiqizo yethu isebenza kahle kakhulu njalo.

Funda Okwengeziwe Ngokushesha:

Ngena Ezweni Lomlingo Lomshini Wokusika Nge-Laser,

Xoxa nochwepheshe wethu we-Laser!

Isikhathi sokuthunyelwe: Meyi-27-2024