Mechini ea ho seha ka laser ke lisebelisoa tsa bohlokoa tlhahisong ea sejoale-joale, e sebelisa mahlaseli a laser a shebaneng le ho seha thepa e fapaneng ka nepo. Ho utloisisa hamolemo mechini ena, ha re aroleng lihlopha tsa eona, likarolo tsa bohlokoa tsaMechini ea ho itšeha ka laser ea CO2, le melemo ea tsona.

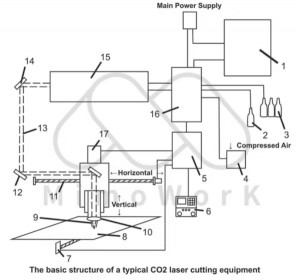

Sebopeho sa Motheo sa Sesebelisoa se Tloaelehileng sa ho Seha Laser sa CO2

Mefuta ea Mechini ea ho Seha ea Laser

Mechini ea ho itšeha ka laser e ka aroloa ka lihlopha ho latela lintlha tse peli tse ka sehloohong:

▶Ka thepa e sebetsang ea laser

Lisebelisoa tsa ho itšeha tsa laser tse tiileng

Lisebelisoa tsa ho seha ka laser ea khase (Mechini ea ho itšeha ka laser ea CO2oela sehlopheng sena)

▶Ka mekhoa ea ho sebetsa ka laser

Lisebelisoa tsa ho itšeha ka laser tse tsoelang pele

Lisebelisoa tsa ho seha tsa laser tse pulsed

Likarolo tsa Bohlokoa tsa Mochini oa ho Seha oa Laser oa CO2

Mochini o tloaelehileng oa ho seha oa laser oa CO2 (o nang le matla a tlhahiso a 0.5-3kW) o na le likarolo tse latelang tsa mantlha.

✔ Sehatsetsi sa Laser

Tube ea Laser ea Co2 (Oscillator ea Laser): karolo ea mantlha e fanang ka mahlaseli a laser.

Phepelo ea Matla ea Laser: e fana ka matla bakeng sa tube ea laser ho boloka tlhahiso ea laser.

Sistimi ea ho Pholisa: joalo ka sesebelisoa sa ho futhumatsa metsi ho pholisa tube ea laser—kaha ke 20% feela ea matla a laser a fetohang leseli (a setseng a fetoha mocheso), sena se thibela ho chesa haholo.

Mochini oa ho seha oa Laser oa CO2

✔ Sistimi ea Optical

Seipone se Bonahatsang: ho fetola tataiso ea ho phatlalatsoa ha lehlaseli la laser ho netefatsa tataiso e nepahetseng.

Seipone se Tsepamisang Maikutlo: e tsepamisa lebone la laser sebakeng sa khanya e nang le matla a mangata ho fihlela ho sehoa.

Sekoahelo sa Tšireletso sa Tsela ea Optical: e sireletsa tsela ea mahlo ho tšitiso e kang lerōle.

✔ Sebopeho sa Mekaniki

Tafole ea mosebetsi: sethala sa ho beha thepa e lokelang ho sehoa, ka mefuta ea ho fepa ka boiketsetso. E tsamaea hantle ho latela mananeo a taolo, hangata e tsamaisoa ke li-stepper kapa li-servo motors.

Sistimi ea Motsamao: ho kenyeletsoa le lireile tse tataisang, likurufu tsa loto, jj., ho khanna tafole ea mosebetsi kapa hlooho ea ho seha ho tsamaea. Mohlala,Seha TocheE na le 'mele oa sethunya sa laser, lense e shebaneng le eona, le nozzle e thusang ea khase, tse sebetsang hammoho ho tsepamisa maikutlo ho laser le ho thusa ho seha.Sesebelisoa sa ho Khaola Torche tsamaisa Torch e Sehang ho latela X-axis (e otlolohileng) le Z-axis (bophahamo bo otlolohileng) ka dikarolo tse kang dienjene le dikurufu tsa loto.

Sesebelisoa sa Phetiso: joalo ka enjene ea servo, ho laola ho nepahala ha motsamao le lebelo.

✔ Sistimi ea Taolo

Sistimi ea CNC (taolo ea lipalo tsa khomphutha): e amohela data ea litšoantšo tse sehiloeng, e laola motsamao oa lisebelisoa tsa tafole ea ho sebetsa le toche ea ho seha, hammoho le matla a tlhahiso ea laser.

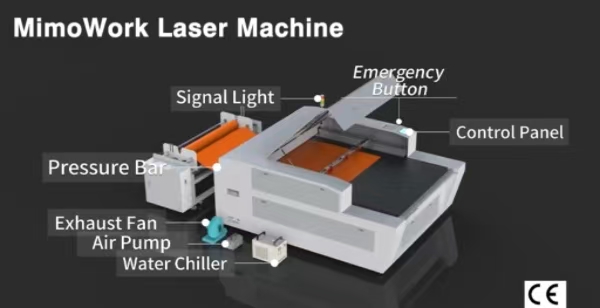

Phanele ea Ts'ebetso: bakeng sa basebelisi ho beha liparamitha, ho qala/ho emisa lisebelisoa, jj.

Sistimi ea Software: e sebelisetsoang moralo oa litšoantšo, moralo oa tsela le ho hlophisa liparamente.

✔ Sistimi e Thusang

Sistimi ea ho Foka Moea: ho phatloha ha likhase tse kang naetrojene le oksijene nakong ea ho seha ho thusa ho seha le ho thibela ho khomarela ha mashala. Mohlala,Pompo ea Moeae fana ka moea o hloekileng, o omileng ho tube ea laser le tsela ea mahlaseli, e netefatsa ts'ebetso e tsitsitseng ea tsela le li-reflector.Lisilindara tsa Khasefana ka khase e mahareng e sebetsang ka laser (bakeng sa ho sisinyeha) le khase e thusang (bakeng sa ho seha).

Sistimi ea ho Tlosa Mosi o Chesang le Lerōle: e tlosa mosi le lerōle le hlahisoang nakong ea ho seha ho sireletsa lisebelisoa le tikoloho.

Lisebelisoa tsa Tšireletso ea Polokeho: tse kang likoahelo tse sireletsang, likonopo tsa ho emisa maemong a tšohanyetso, li-interlock tsa polokeho tsa laser, jj.

Melemo ea Mechini ea ho Seha ea Laser ea CO2

Mechini ea ho seha ea laser ea CO2 e sebelisoa haholo ka lebaka la likarolo tsa eona:

▪Ho nepahala ho hoholo, e leng se fellang ka ho seha ho hloekileng le ho nepahetseng.

▪Ho feto-fetoha ha maemoho seheng thepa e fapaneng (mohlala, lehong, acrylic, lesela le litšepe tse itseng).

▪Ho ikamahanya le maemoho ts'ebetso e tsoelang pele le e tsamaeang ka lebelo, e lumellanang le litlhoko tse fapaneng tsa thepa le botenya.

▪Bokgoni, e nolofalletsoang ke taolo ea CNC bakeng sa ts'ebetso e iketsahallang le e tsitsitseng.

Livideo tse Amanang:

Li-cutter tsa Laser li sebetsa joang?

Sehahi sa CO2 Laser se tla nka nako e kae?

Lintlha tsa ho Reka Laser Cutter mose ho maoatle

Lipotso Tse Botsoang Khafetsa

E!

O ka sebedisa sefaha sa laser ka tlung, empa moya o nepahetseng wa ho kenya moya o bohlokwa. Mosi o ka senya dikarolo tse kang lense le diipone ha nako e ntse e ya. Karache kapa sebaka sa mosebetsi se arohaneng se sebetsa hantle.

Hobane tube ea laser ea CO2 ke laser ea Sehlopha sa 4. Mahlaseli a laser a bonahalang le a sa bonahaleng a teng, kahoo qoba ho pepesehela mahlo kapa letlalo la hao ka kotloloho kapa ka tsela e sa tobang.

Ho hlahisa laser, e leng se nolofalletsang ho seha kapa ho betla thepa eo u e khethileng, ho etsahala ka har'a tube ea laser. Bahlahisi hangata ba bolela nako ea bophelo ba lipeipi tsena, 'me hangata e pakeng tsa lihora tse 1,000 le 10,000.

- Hlakola libaka, lireile le mabone ka lisebelisoa tse bonolo ho tlosa lerōle le masalla.

- Tlotsa likarolo tse tsamaeang joalo ka lireile nako le nako ho fokotsa ho tsofala.

- Hlahloba maemo a sehatsetsi, nkela sebaka ha ho hlokahala, 'me u hlahlobe hore na ha ho na ho dutla.

- Netefatsa hore dikheibole/dihokelo di ntse di tiile; boloka khabinete e se na lerole.

- Lumellanya lilense/liipone khafetsa; nkela tse tsofetseng sebaka kapele.

- Qoba ho jara lintho tse ngata haholo, sebelisa thepa e loketseng, 'me u e koale hantle.

Hlahloba jenereithara ea laser: khatello/mocheso oa khase (e sa tsitsang →e sehiloeng se se nang letho). Haeba e le ntle, hlahloba optics: litšila/ho tsofala (mathata →e sehiloeng se se nang letho); lokisa tsela hape haeba ho hlokahala.

Re Bo-mang:

Mosebetsi oa Mimoke koporasi e shebaneng le diphetho e tlisang boiphihlelo bo tebileng ba dilemo tse 20 ba tshebetso ho fana ka ditharollo tsa ts'ebetso ya laser le tlhahiso ho di-SME (dikgwebo tse nyane le tse mahareng) kahare le haufi le diaparo, dikoloi, le sebaka sa dipapatso.

Phihlelo ea rona e ruileng ea litharollo tsa laser e metse ka metso lipapatsong, likoloi le lifofaneng, fesheneng le liaparong, khatisong ea dijithale le indastering ea masela a sefe e re lumella ho potlakisa khoebo ea hau ho tloha leanong ho ea ts'ebetsong ea letsatsi le letsatsi.

Re lumela hore boiphihlelo bo nang le mahlale a fetohang ka potlako, a ntseng a hlaha moo ho kopanang tlhahiso, boqapi, theknoloji le khoebo ke phapang.

Hamorao, re tla hlalosa ka botlalo ka livideo le lihlooho tse bonolo mabapi le karolo ka 'ngoe ho u thusa ho utloisisa hamolemo lisebelisoa tsa laser le ho tseba hore na ke mofuta ofe oa mochini o u tšoanelang hantle pele u reka o mong. Re boetse re u amohela hore u re botse ka kotloloho: info@mimowork.com

Na ho na le Lipotso Mabapi le Mochini oa Rona oa Laser?

Nako ea poso: Mmesa-29-2021