Laser cutting machines are essential tools in modern manufacturing, using focused laser beams to cut through various materials with precision. To better understand these machines, let’s break down their classifications, the key components of CO2 laser cutting machines, and their advantages.

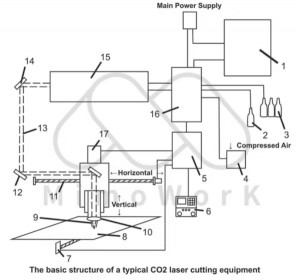

The Basic Structure of A Typical CO2 Laser Cutting Equipment

Types of Laser Cutting Machines

Laser cutting machines can be categorized based on two main criteria:

▶By laser working materials

Solid laser cutting equipment

Gas laser cutting equipment (CO2 laser cutting machines fall into this category)

▶By laser working methods

Continuous laser cutting equipment

Pulsed laser cutting equipment

Key Components of A CO2 Laser Cutting Machine

A typical CO2 laser cutting machine (with an output power of 0.5-3kW) consists of the following core components.

✔ Laser Resonator

Co2 Laser Tube (Laser Oscillator): the core component that provides the laser beam.

Laser Power Supply: provides energy for the laser tube to maintain laser generation.

Cooling System: such as a water chiller to cool the laser tube—since only 20% of the laser’s energy converts to light (the rest becomes heat), this prevents overheating.

CO2 Laser Cutter Machine

✔ Optical System

Reflecting Mirror: to change the propagation direction of the laser beam to ensure precise guidance.

Focusing Mirror: focuses the laser beam into a high-energy-density light spot to achieve cutting.

Optical Path Protective Cover: protects the optical path from interference such as dust.

✔ Mechanical Structure

Worktable: a platform for placing materials to be cut, with automatic feeding types.It moves precisely according to control programs, usually driven by stepper or servo motors.

Motion System: including guide rails, lead screws, etc., to drive the worktable or cutting head to move. For example, Cutting Torch Comprises a laser gun body, focusing lens, and auxiliary gas nozzle, working together to focus the laser and assist in cutting. Cutting Torch Driving Device moves the Cutting Torch along the X-axis (horizontal) and Z-axis (vertical height) via components like motors and lead screws.

Transmission Device: such as a servo motor, to control motion precision and speed.

✔ Control System

CNC System (computer numerical control) : receives cutting graphic data, controls equipment movement of the working table and cutting torch, as well as the laser’s output power.

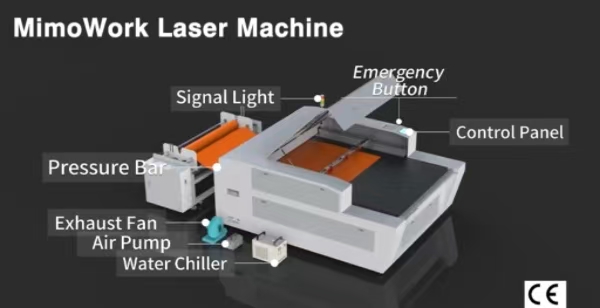

Operation Panel: for users to set parameters, start/stop equipment, etc..

Software System: used for graphic design, path planning and parameter editing.

✔ Auxiliary System

Air Blowing System: blows in gases such as nitrogen and oxygen during cutting to assist cutting and prevent slag adhesion. For example, Air Pump delivers clean, dry air to the laser tube and beam path, ensuring stable operation of the path and reflectors. Gas Cylinders supply laser working medium gas (for oscillation) and auxiliary gas (for cutting).

Smoke Exhaust and Dust Removal System: removes smoke and dust generated during cutting to protect equipment and the environment.

Safety Protection Devices: such as protective covers, emergency stop buttons, laser safety interlocks, etc..

Advantages of CO2 Laser Cutting Machines

CO2 laser cutting machines are widely used due to their features:

▪ High precision, resulting in clean, accurate cuts.

▪ Versatility in cutting various materials (e.g., wood, acrylic, fabric, and certain metals).

▪ Adaptability to both continuous and pulsed operation, suiting different material and thickness requirements.

▪ Efficiency, enabled by CNC control for automated, consistent performance.

Related Videos:

How Do Laser Cutters Work?

How Long Will A CO2 Laser Cutter Last?

Notes for Buying Laser Cutter Overseas

FAQs

Yes!

You can use a laser engraver indoors, but proper ventilation is crucial. Fumes can damage components like the lens and mirrors over time. A garage or separate workspace works best.

Because CO2 laser tube is a Class 4 laser. Both visible and invisible laser radiation are present, so avoid direct or indirect exposure to your eyes or skin.

Laser generation, which enables cutting or engraving of your chosen material, happens inside the laser tube. Manufacturers typically state a lifespan for these tubes, and it’s usually in the range of 1,000 to 10,000 hours.

- Wipe surfaces, rails, and optics with soft tools to remove dust and residues.

- Lubricate moving parts like rails periodically to reduce wear.

- Check coolant levels, replace as needed, and inspect for leaks.

- Ensure cables/connectors are intact; keep the cabinet dust-free.

- Align lenses/mirrors regularly; replace worn ones promptly.

- Avoid overloading, use suitable materials, and shut down correctly.

Check laser generator: gas pressure/temp (unstable→rough cuts).If good, check optics: dirt/wear (issues→rough cuts); re-align path if needed.

Who Are We:

Mimowork is a results-oriented corporation bringing 20-year deep operational expertise to offer laser processing and production solutions to SMEs (small and medium-sized enterprises) in and around clothing, auto, ad space.

Our rich experience of laser solutions deeply rooted in the advertisement, automotive & aviation, fashion & apparel, digital printing, and filter cloth industry allows us to accelerate your business from strategy to day-to-day execution.

We believe that expertise with fast-changing, emerging technologies at the crossroads of manufacture, innovation, technology, and commerce are a differentiator.

Later, we will go into more detail by simple videos and articles on each of the components to help you better understand the laser equipment and know what kind of machine suits you best before you actually purchase one. We also welcome you ask us directly: info@mimowork. com

Any Questions About Our Laser Machine?

Post time: Apr-29-2021