Kodi kuyeretsa kwa laser ndi chiyani?

Mwa kuyika mphamvu ya laser yokhazikika pamwamba pa workpiece yoipitsidwa, kuyeretsa kwa laser kumatha kuchotsa dothi nthawi yomweyo popanda kuwononga njira ya substrate. Ndi chisankho chabwino kwambiri cha mbadwo watsopano wa ukadaulo woyeretsa mafakitale.

Ukadaulo woyeretsa pogwiritsa ntchito laser wakhalanso ukadaulo wofunikira kwambiri woyeretsa m'makampani, kupanga zombo, ndege, ndi madera ena apamwamba opangira zinthu, kuphatikizapo kuchotsa dothi la rabara pamwamba pa matayala, kuchotsa zodetsa za mafuta a silicon pamwamba pa filimu yagolide, komanso kuyeretsa bwino kwambiri mafakitale a ma microelectronics.

Ntchito zoyeretsera za laser zomwe zimagwiritsidwa ntchito nthawi zambiri

◾ Kuchotsa Utoto

◾ Kuchotsa Mafuta

◾ Kuchotsa Oxide

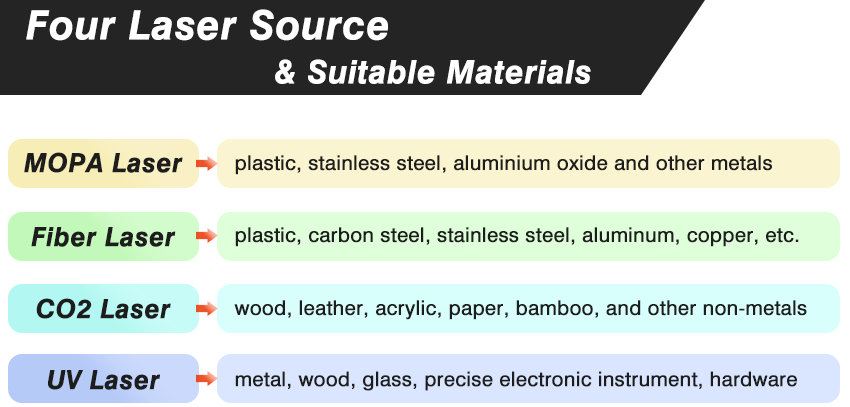

Pa ukadaulo wa laser monga kudula laser, kujambula laser, kuyeretsa laser, ndi kuwotcherera laser, mutha kudziwa izi koma gwero la laser logwirizana. Pali fomu yoti mugwiritse ntchito yomwe ili ndi magwero anayi a laser ndi zipangizo zoyenera komanso ntchito.

Magwero anayi a laser okhudza kuyeretsa laser

Chifukwa cha kusiyana kwa magawo ofunikira monga kutalika kwa nthawi ndi mphamvu ya magwero osiyanasiyana a laser, kuchuluka kwa kuyamwa kwa zinthu zosiyanasiyana ndi madontho, kotero muyenera kusankha gwero loyenera la laser la makina anu oyeretsera laser malinga ndi zofunikira zochotsera zodetsa.

▶ Kuyeretsa kwa Laser ya MOPA Pulse

(kugwira ntchito pazinthu zonse)

Laser ya MOPA ndiyo njira yodziwika kwambiri yoyeretsera laser. MO imayimira master oscillator. Popeza MOPA fiber laser system imatha kukulitsidwa motsatira gwero la chizindikiro cha mbewu lomwe limalumikizidwa ndi dongosololi, makhalidwe oyenera a laser monga kutalika kwa nthawi yapakati, mawonekedwe a pulse waveform ndi m'lifupi mwa pulse sizingasinthidwe. Chifukwa chake, kukula kwa kusintha kwa magawo kumakhala kwakukulu ndipo mulingo wake ndi wokulirapo. Pazinthu zosiyanasiyana zogwiritsira ntchito zipangizo zosiyanasiyana, kusinthasintha kumakhala kolimba ndipo nthawi yogwiritsira ntchito zenera ndi yayikulu, yomwe ingakwaniritse kuyeretsa pamwamba pa zipangizo zosiyanasiyana.

▶ Kuyeretsa kwa Laser ya Composite Fiber

(chisankho chabwino kwambiri chochotsera utoto)

Kuyeretsa kophatikizana ndi laser kumagwiritsa ntchito laser yopitilira ya semiconductor kuti ipange mphamvu yotulutsa kutentha, kotero kuti gawo loyeretsera limatenga mphamvu kuti lipange mpweya, ndi mtambo wa plasma, ndikupanga kupsinjika kwa kutentha pakati pa zinthu zachitsulo ndi wosanjikiza woipitsidwa, kuchepetsa mphamvu yolumikizirana pakati pa wosanjikiza. Pamene gwero la laser lipanga kuwala kwa laser yamphamvu kwambiri, mafunde ogwedezeka a kugwedezeka amachotsa cholumikiziracho ndi mphamvu yofooka yolumikizira, kuti ayeretsedwe mwachangu ndi laser.

Kuyeretsa kophatikizana kwa laser kumaphatikiza ntchito za laser ndi pulsed laser nthawi imodzi. Liwiro lapamwamba, kugwira ntchito bwino kwambiri, komanso kuyeretsa kofanana, pazida zosiyanasiyana, kungagwiritsenso ntchito mafunde osiyanasiyana a laser nthawi imodzi kuti akwaniritse cholinga chochotsa madontho.

Mwachitsanzo, poyeretsa zipangizo zokhuthala pogwiritsa ntchito laser, mphamvu ya single laser multi-pulse energy imachokera pamlingo waukulu ndipo mtengo wake ndi wokwera. Kuyeretsa kophatikizana kwa pulsed laser ndi semiconductor laser kungathandize kukonza bwino ntchito yoyeretsa mwachangu komanso moyenera, ndipo sikuwononga substrate. Poyeretsa zinthu zowala kwambiri monga aluminiyamu, laser imodzi imakhala ndi mavuto monga kuwunikira kwambiri. Pogwiritsa ntchito pulse laser ndi semiconductor laser composite cleaning, pogwiritsa ntchito semiconductor laser thermal conduction transmission, kumawonjezera mphamvu ya okosijeni pamwamba pa chitsulo, kuti kuwala kwa pulse laser kuthe kuchotsa okosijeni mwachangu, kuwonjezere mphamvu yochotsera bwino, makamaka mphamvu yochotsa utoto imawonjezeka ndi nthawi zoposa ziwiri.

▶ Kuyeretsa kwa CO2 Laser

(chisankho chabwino kwambiri choyeretsera zinthu zopanda chitsulo)

Laser ya kaboni dioxide ndi laser ya mpweya yokhala ndi mpweya wa CO2 ngati chinthu chogwirira ntchito, yomwe imadzazidwa ndi mpweya wa CO2 ndi mpweya wina wothandizira (helium ndi nayitrogeni komanso kuchuluka kochepa kwa haidrojeni kapena xenon). Kutengera kutalika kwake kwa nthawi, laser ya CO2 ndiyo njira yabwino kwambiri yoyeretsera pamwamba pa zinthu zopanda chitsulo monga kuchotsa guluu, zokutira ndi inki. Mwachitsanzo, kugwiritsa ntchito laser ya CO2 kuchotsa utoto wophatikizika pamwamba pa aluminiyamu sikuwononga pamwamba pa filimu ya anodic oxide, komanso sikuchepetsa makulidwe ake.

▶ Kuyeretsa ndi Laser ya UV

(chisankho chabwino kwambiri pa chipangizo chamagetsi chapamwamba)

Ma laser a ultraviolet omwe amagwiritsidwa ntchito mu ma micromachining a laser makamaka amaphatikizapo ma laser a excimer ndi ma laser onse olimba. Kutalika kwa ultraviolet laser ndi kochepa, photon iliyonse imatha kupereka mphamvu zambiri, imatha kuswa mwachindunji mgwirizano wa mankhwala pakati pa zipangizo. Mwanjira imeneyi, zipangizo zophimbidwa zimachotsedwa pamwamba ngati mpweya kapena tinthu tating'onoting'ono, ndipo njira yonse yoyeretsera imapanga mphamvu yochepa yotentha yomwe ingakhudze gawo laling'ono pa workpiece. Zotsatira zake, kuyeretsa kwa UV laser kuli ndi ubwino wapadera popanga zinthu zazing'ono, monga kuyeretsa Si, GaN ndi zipangizo zina za semiconductor, quartz, safiro ndi makristalo ena optical, Ndipo polyimide (PI), polycarbonate (PC) ndi zipangizo zina za polima, zimatha kusintha bwino mtundu wa kupanga.

Laser ya UV imaonedwa kuti ndi njira yabwino kwambiri yoyeretsera laser m'munda wa zamagetsi olondola, ukadaulo wake wodziwika bwino kwambiri wokonza "ozizira" susintha mawonekedwe enieni a chinthucho nthawi imodzi, pamwamba pa makina ang'onoang'ono ndi kukonza, ungagwiritsidwe ntchito kwambiri polankhulana, kuyang'ana kuwala, usilikali, kufufuza milandu, zamankhwala ndi mafakitale ena. Mwachitsanzo, nthawi ya 5G yapanga kufunikira kwa msika kwa kukonza kwa FPC. Kugwiritsa ntchito makina a UV laser kumapangitsa kuti zikhale zotheka kukonza molondola FPC ndi zipangizo zina.

Nthawi yotumizira: Okutobala-10-2022