Waa maxay nadiifinta laysarka

Adiga oo soo bandhigaya tamarta leysarka ee xoogga leh ee dusha shaqada wasakhaysan, nadiifinta layserku waxay isla markiiba ka saari kartaa lakabka wasakhda iyada oo aan waxyeello u geysan habka substrate-ka.Waa doorashada ugu habboon ee jiilka cusub ee tignoolajiyada nadiifinta warshadaha.

Tiknoolajiyada nadiifinta laser-ka waxay sidoo kale noqotay tignoolajiyada nadiifinta lagama maarmaanka ah ee warshadaha, dhisitaanka maraakiibta, hawada hawada, iyo meelaha kale ee wax soo saarka ee heer-sare ah, oo ay ku jiraan ka saarida wasakhda caagga ah ee dusha sare ee caaryada taayirka, ka saarida wasakhda saliidda silikoon ee dusha sare ee dahabka. filimka, iyo nadiifinta saxda ah ee sare ee warshadaha microelectronics.

Codsiyada nadiifinta laysarka caadiga ah

◾ Rinjiyeynta Rinjiga

◾ Saliidda oo la saaro

◾ Ka saarista oksaydhka

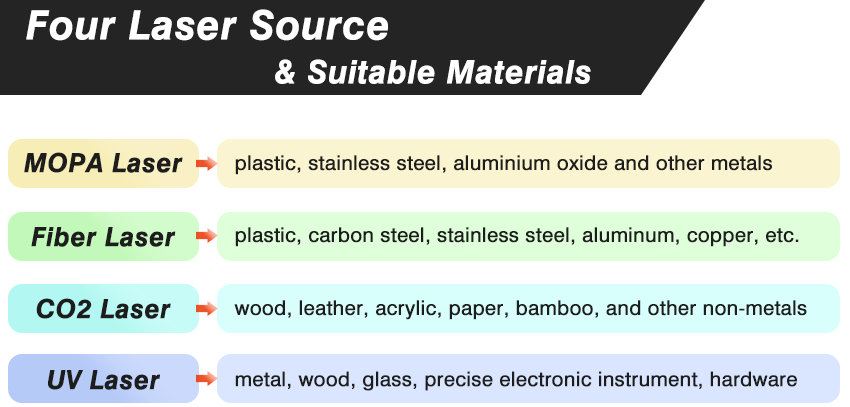

Tignoolajiyada laysarka sida goynta laysarka, xaradhka laysarka, nadiifinta laysarka, alxanka laysarka, waxa laga yaabaa inaad taqaan kuwan laakiin isha laserka ee la xidhiidha.Waxaa jira foom loogu talagalay tixraacaada kaas oo ku saabsan afar ilood oo laysarka ah iyo qalab iyo codsiyo ku habboon oo u dhigma.

Afar il oo laser ah oo ku saabsan nadiifinta laysarka

Sababtoo ah kala duwanaanshaha xuduudaha muhiimka ah sida dhererka dhererka iyo awoodda ilaha kala duwan ee laysarka, heerka nuugista walxaha kala duwan iyo wasakhda, markaa waxaad u baahan tahay inaad doorato isha saxda ah ee laser-kaaga mashiinka nadiifinta laysarka iyadoo loo eegayo shuruudaha ka saarista wasakheynta gaarka ah.

▶ MOPA Pulse Laser Nadiifinta

(ka shaqaynta dhammaan noocyada agabka)

Laser MOPA waa nooca ugu isticmaalka badan ee nadiifinta laysarka.MO waxay u taagan tahay master oscillator.Maaddaama nidaamka laser fiber MOPA si adag loo xoojin karo si waafaqsan isha isha abuurka ee lagu weheliyo nidaamka, sifooyinka la xidhiidha laysarka sida hirarka dhexda, waveform garaaca wadnaha iyo ballaca garaaca wadnaha lama beddeli doono.Sidaa darteed, cabbirka hagaajinta halbeeggu wuu sarreeyaa, cabbirkuna wuu ka sii ballaadhan yahay.Xaalado kala duwan oo codsi ah oo qalabyo kala duwan ah, la qabsigu waa ka sii xoog badan yahay iyo muddada u dhaxaysa daaqadaha habka waa ka weyn yahay, kaas oo la kulmi kara nadiifinta dusha sare ee alaabta kala duwan.

▶ Nadiifinta Fiber Laser-ka isku dhafan

(doorashada ugu fiican ee rinjiga saarista)

Nadiifinta isku dhafka Laser waxay isticmaashaa semiconductor laser joogto ah si ay u soo saarto wax soo saarka kulaylka, si substrate-ka la nadiifiyo uu nuugo tamarta si loo soo saaro gaas, iyo balasmaha, oo sameeya cadaadiska fidinta kuleylka u dhexeeya walxaha birta iyo lakabka wasakhaysan, taas oo yaraynaysa xoogga isku xidhka interlayer.Marka isha laysarka uu dhaliyo tamar sare oo garaaca leysarka, mawjada shoogga gariirku waxay ka fujin doontaa ku-xidhka xoogga adhesion-ka daciifka ah, si loo gaaro nadiifinta laser degdeg ah.

Nadiifinta isku dhafka ah ee leysarka waxay isku daraysaa laysarka joogtada ah iyo hawlaha laser garaaca isku mar.Xawaaraha sare, wax ku oolnimada sare, iyo tayada nadiifinta lebbiska oo dheeraad ah, qalabyo kala duwan, waxay sidoo kale isticmaali karaan mowjadaha kala duwan ee nadiifinta laysarka isku mar si loo gaaro ujeedada ka saarista wasakhda.

Tusaale ahaan, nadiifinta laysarka ee alaabta daahan qaro weyn, hal laser multi-pulse tamarta wax soo saarka waa weyn yahay iyo qiimaha sare.Nadiifinta isku dhafan ee leysarka garaaca iyo semiconductor laser waxay si dhakhso ah oo wax ku ool ah u wanaajin kartaa tayada nadiifinta, oo aan waxyeello u geysan substrate-ka.Nadiifinta laysarka ee walxaha aadka u iftiimaya sida aluminium aluminium, hal laser ayaa leh dhibaatooyin qaarkood sida milicsiga sare.Isticmaalka laysarka garaaca wadnaha iyo semiconductor laser nadiifinta isku dhafan, iyadoo la raacayo ficilka gudbinta kuleylka laser semiconductor, kordhinta heerka nuugista tamarta lakabka oksaydhka ee dusha birta ah, si laysarka garaaca wadnaha uu u dilo lakabka oksaydhka si dhakhso ah, hagaajinta waxtarka saarista si wax ku ool ah, gaar ahaan waxtarka ka saarista rinjiga ayaa kordhay in ka badan 2 jeer.

▶ CO2 Laser Nadiifinta

(doorashada ugu fiican ee nadiifinta walxaha aan birta ahayn)

Laser kaarboon dioxide waa laser gaas leh CO2 gaaska oo ah walxaha shaqada, kaas oo ay ka buuxaan gaaska CO2 iyo gaasaska kale ee caawiya (helium iyo nitrogen iyo sidoo kale qadar yar oo hydrogen ama xenon ah).Iyada oo ku saleysan mowjadda dhererkeeda gaarka ah, CO2 laser ayaa ah doorashada ugu fiican ee lagu nadiifiyo dusha walxaha aan biraha ahayn sida qaadista xabagta, dahaarka iyo khad.Tusaale ahaan, isticmaalka CO2 laser si loo saaro lakabka rinjiga isku dhafan ee dusha sare ee aluminium aluminium ma dhaawici dusha filimka anodic oxide, mana yarayso dhumucdeeda.

▶ Nadiifinta UV Laser

(doorashada ugu fiican ee qalabka elegtarooniga ah ee casriga ah)

Laysarka ultraviolet ee loo isticmaalo micromachining laser-ka inta badan waxaa ka mid ah lasers excimer iyo dhammaan lasers-state adag.Dhererka mowjadda laysarka ee ultraviolet waa gaaban yahay, mid kasta oo sawir qaade ah ayaa bixin kara tamar sare, si toos ah ayuu u jebin karaa curaarta kiimikada ee u dhexeysa alaabta.Sidan oo kale, walxaha dahaarka leh ayaa laga saaraa dusha sare ee qaabka gaasta ama qaybaha, iyo dhammaan habka nadiifinta waxay soo saaraan tamar kuleyl hooseeya oo saameyn doona oo kaliya aag yar oo ku yaala shaqada.Natiijo ahaan, nadiifinta laser UV waxay leedahay faa'iidooyin gaar ah oo ku saabsan wax soo saarka micro, sida nadiifinta Si, GaN iyo walxaha kale ee semiconductor, quartz, sapphire iyo kiristaalo kale oo indhaha ah, iyo polyimide (PI), polycarbonate (PC) iyo walxaha kale ee polymer, waxay si wax ku ool ah u karaan. hagaajinta tayada wax soo saarka.

Laser UV waxaa loo arkaa inuu yahay nidaamka nadiifinta laser ugu fiican berrinkii elektiroonigga saxda ah, ay ugu sifo wanaagsan technology processing "qabow" ma beddelo sifooyinka jireed ee shayga isku mar, dusha sare ee machining micro iyo processing, karaa in si weyn loogu isticmaalo isgaarsiinta, indhaha, ciidamada, baarista dembiyada, caafimaadka iyo warshadaha iyo goobaha kale.Tusaale ahaan, waagii 5G waxa uu abuuray baahida suuqa ee habaynta FPC.Codsiga mashiinka laysarka UV wuxuu suurtogal ka dhigayaa in la saxo mashiinnada qabow ee FPC iyo agabyada kale.

Waqtiga boostada: Oct-10-2022