Waa maxay nadiifinta laysarka

Iyadoo tamarta laysarka ee xooggan la soo bandhigayo dusha sare ee shaqada wasakhaysan, nadiifinta laysarka waxay isla markiiba ka saari kartaa lakabka wasakhda iyada oo aan waxyeello u geysanayn habka substrate-ka. Waa doorashada ugu habboon jiilka cusub ee tignoolajiyada nadiifinta warshadaha.

Tiknoolajiyadda nadiifinta laysarka ayaa sidoo kale noqotay tignoolajiyad nadiifin oo aan laga maarmi karin warshadaha, dhismaha maraakiibta, hawada sare, iyo goobaha kale ee wax soo saarka ee heerka sare ah, oo ay ku jiraan ka saarista wasakhda caagga ah ee dusha sare ee caaryada taayirada, ka saarista wasakhda saliidda silikoon ee dusha sare ee filimka dahabka ah, iyo nadiifinta saxda ah ee warshadaha microelectronics.

Codsiyada nadiifinta laser-ka caadiga ah

◾ Ka saarista Rinjiga

◾ Ka saarista Saliidda

Ka saarista oksaydhka

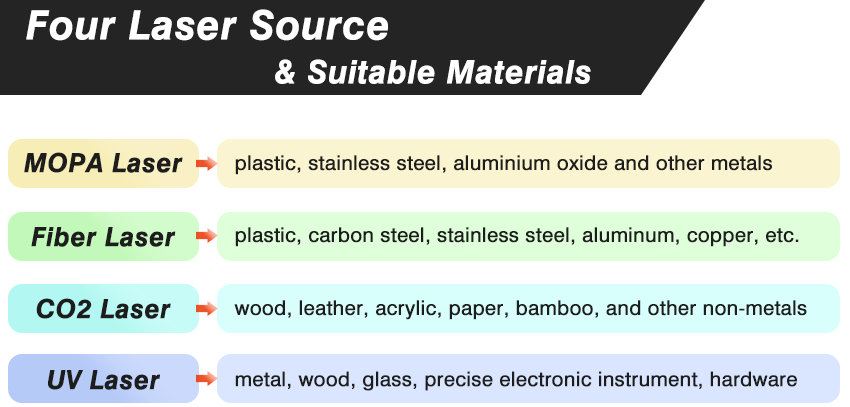

Tiknoolajiyada laysarka sida jarista laysarka, qorista laysarka, nadiifinta laysarka, iyo alxanka laysarka, waxaa laga yaabaa inaad taqaanid kuwan laakiin isha laysarka ee la xiriirta. Waxaa jira foom loogu talagalay tixraacaaga kaas oo ah qiyaastii afar ilo laysarka ah iyo agab iyo codsiyo ku habboon oo u dhigma.

Afar ilo laysar ah oo ku saabsan nadiifinta laysarka

Sababo la xiriira kala duwanaanshaha xuduudaha muhiimka ah sida hirarka iyo awoodda isha laysarka ee kala duwan, heerka nuugista agabka kala duwan iyo wasakhda, markaa waxaad u baahan tahay inaad doorato isha laysarka ee saxda ah ee mashiinkaaga nadiifinta laysarka iyadoo loo eegayo shuruudaha gaarka ah ee ka saarista wasakhda.

▶ Nadiifinta Laser-ka garaaca wadnaha ee MOPA

(ka shaqaynta dhammaan noocyada agabka)

Laser-ka MOPA waa nooca ugu badan ee nadiifinta laysarka ee loo isticmaalo. MO wuxuu u taagan yahay oscillator-ka weyn. Maadaama nidaamka laysarka fiilada MOPA lagu kordhin karo si adag iyadoo la raacayo isha calaamadda abuurka ee ku xiran nidaamka, astaamaha khuseeya ee laysarka sida hirarka dhexe, qaabka hirarka garaaca iyo ballaca garaaca lama beddeli doono. Sidaa darteed, cabbirka hagaajinta halbeegga ayaa sarreeya baaxadduna waa ballaaran tahay. Xaaladaha kala duwan ee codsiyada ee agabka kala duwan, la qabsiga ayaa ka xoog badan oo muddada daaqadda geeddi-socodka ayaa ka weyn, taas oo dabooli karta nadiifinta dusha sare ee agabyada kala duwan.

▶ Nadiifinta Laser-ka Fiber-ka Isku-dhafan

(doorashada ugu fiican ee ka saarista rinjiga)

Nadiifinta isku-dhafka ah ee laysarka waxay isticmaashaa laysarka joogtada ah ee semiconductor-ka si ay u soo saarto wax soo saarka gudbinta kulaylka, si substrate-ka la nadiifinayo uu u nuugo tamarta si uu u soo saaro gaas-saarid, iyo daruur balaasma ah, oo uu sameeyo cadaadis ballaarinta kulaylka oo u dhexeeya walxaha birta ah iyo lakabka wasakhaysan, taasoo yaraynaysa xoogga isku xidhka lakabka dhexe. Marka isha laysarka ay soo saarto shucaac laysar garaaca oo tamar sare leh, hirarka shoogga gariirku wuxuu ka saari doonaa lifaaqa xoogga isku dhejinta ee daciifka ah, si loo gaaro nadiifin laysar oo degdeg ah.

Nadiifinta isku-dhafka ah ee laysarka waxay isku daraysaa shaqooyinka laysarka joogtada ah iyo kuwa garaaca wadnaha isku mar. Xawaaraha sare, hufnaanta sare, iyo tayada nadiifinta oo isku mid ah, ee agabyada kala duwan, waxay sidoo kale isticmaali kartaa hirar kala duwan oo nadiifinta laysarka ah isla waqtigaas si loo gaaro ujeeddada ka saarista wasakhda.

Tusaale ahaan, nadiifinta laysarka ee walxaha dahaarka qaro weyn, wax soo saarka tamarta hal laysarka badan ee garaaca wadnaha ayaa weyn kharashkuna waa sarreeyaa. Nadiifinta isku-dhafka ah ee laysarka garaaca wadnaha iyo laysarka semiconductor-ka ayaa si dhakhso leh oo wax ku ool ah u hagaajin karta tayada nadiifinta, mana keento waxyeello substrate-ka. Nadiifinta laysarka ee walxaha aadka u milicsiga badan sida aluminiumka, laysarka hal wuxuu leeyahay dhibaatooyin sida soo-jiidashada sare. Isticmaalka nadiifinta isku-dhafka ah ee laysarka garaaca wadnaha iyo laysarka semiconductor-ka, iyadoo la adeegsanayo gudbinta kulaylka laysarka semiconductor-ka, waxay kordhisaa heerka nuugista tamarta ee lakabka oksaydhka ee dusha sare ee birta, si laysarka garaaca uu si dhakhso leh u dili karo lakabka oksaydhka, si wax ku ool ah u wanaajiyo hufnaanta ka saarista, gaar ahaan hufnaanta ka saarista rinjiga waxaa kordha in ka badan 2 jeer.

▶ Nadiifinta laysarka CO2

(doorashada ugu fiican ee nadiifinta walxaha aan birta ahayn)

Laser-ka kaarboon laba ogsaydh waa laser gaas ah oo leh gaas CO2 ah oo ah agabka shaqada, kaas oo ka buuxa gaas CO2 iyo gaasas kale oo kaaliye ah (helium iyo nitrogen iyo sidoo kale xaddi yar oo haydarojiin ama xenon ah). Iyada oo ku saleysan hirarkiisa gaarka ah, laser-ka CO2 waa doorashada ugu fiican ee lagu nadiifinayo dusha sare ee walxaha aan birta ahayn sida ka saarista xabagta, dahaarka iyo khad. Tusaale ahaan, isticmaalka laser-ka CO2 si looga saaro lakabka rinjiga ee isku dhafan ee dusha sare ee aluminium-ka ma waxyeeleeyo dusha sare ee filimka anodic oxide, mana yareeyo dhumucdiisa.

▶ Nadiifinta laysarka UV

(doorashada ugu fiican ee qalabka elektaroonigga ah ee casriga ah)

Laydhka Ultraviolet-ka ee loo isticmaalo micromachining-ka laser-ka waxaa inta badan ku jira laydhka excimer iyo dhammaan laydhka adag. Mowjadaha laser-ka Ultraviolet-ka waa gaaban yihiin, photon kasta wuxuu keeni karaa tamar sare, wuxuu si toos ah u jebin karaa isku xidhka kiimikada ee u dhexeeya agabka. Sidan, walxaha dahaarka leh waxaa laga saaraa dusha sare qaab gaas ama walxo, habka nadiifinta oo dhanna wuxuu soo saaraa tamar kuleyl oo hooseeya oo saameyn doonta oo keliya aag yar oo ku yaal shaqada. Natiijo ahaan, nadiifinta laser-ka UV waxay leedahay faa'iidooyin gaar ah oo ku saabsan wax soo saarka yar, sida nadiifinta Si, GaN iyo agabyada kale ee semiconductor-ka, quartz, sapphire iyo kiristaalo kale oo indhaha ah, Iyo polyimide (PI), polycarbonate (PC) iyo agabyada kale ee polymer-ka, waxay si wax ku ool ah u horumarin karaan tayada wax soo saarka.

Laser-ka UV waxaa loo arkaa inuu yahay nidaamka nadiifinta laysarka ugu fiican ee dhinaca qalabka elektaroonigga saxda ah, tignoolajiyada farsamaynta ee "qabow" ee ugu caansan ma beddesho sifooyinka jireed ee shayga isla waqtigaas, dusha sare ee mishiinka yar yar iyo farsamaynta, waxaa si weyn loogu isticmaali karaa isgaarsiinta, indhaha, militariga, baaritaanka dambiyada, warshadaha caafimaadka iyo kuwa kale iyo beeraha. Tusaale ahaan, xilligii 5G wuxuu abuuray baahi suuqeed oo loogu talagalay farsamaynta FPC. Codsiga mashiinka laysarka UV wuxuu suurtogal ka dhigayaa in si sax ah loo farsameeyo FPC iyo agabyada kale.

Waqtiga boostada: Oktoobar-10-2022