Menene tsaftacewar laser

Ta hanyar fallasa ƙarfin laser mai ƙarfi a saman kayan aikin da ya gurɓata, tsaftace laser na iya cire layin datti nan take ba tare da lalata tsarin substrate ba. Wannan shine zaɓi mafi kyau ga sabuwar ƙarni na fasahar tsaftacewa ta masana'antu.

Fasahar tsaftacewa ta Laser ta kuma zama wata fasaha ta tsaftacewa mai mahimmanci a masana'antu, gina jiragen ruwa, sararin samaniya, da sauran fannoni masu inganci, gami da cire dattin roba a saman molds na taya, cire gurɓatattun mai na silicon a saman fim ɗin zinare, da kuma tsaftace masana'antar microelectronics mai inganci.

Aikace-aikacen tsaftacewar laser na yau da kullun

◾ Cire Fenti

◾ Cire Mai

Cirewar Oxide

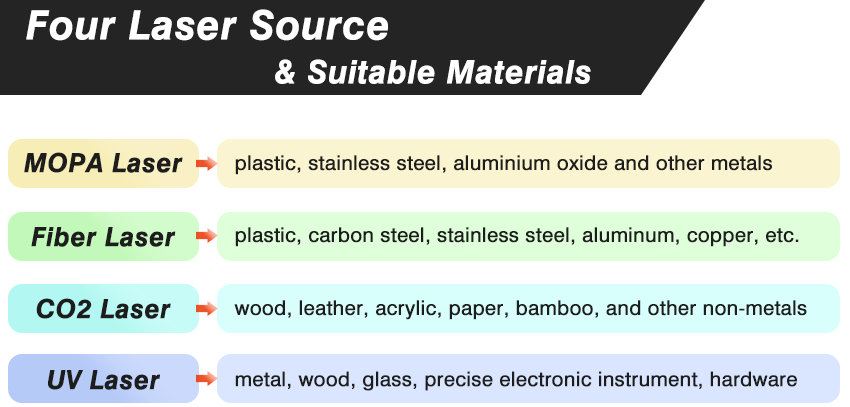

Ga fasahar Laser kamar yanke Laser, sassaka Laser, tsaftace Laser, da walda Laser, za ku iya saba da waɗannan amma tushen Laser ɗin da ke da alaƙa. Akwai fom don bayanin ku wanda ya ƙunshi kusan tushen Laser guda huɗu da kayan aiki da aikace-aikace masu dacewa.

Tushen Laser guda huɗu game da tsaftacewar Laser

Saboda bambance-bambancen da ke cikin muhimman sigogi kamar tsawon rai da ƙarfin tushen laser daban-daban, yawan sha na kayan aiki daban-daban da tabo, don haka kuna buƙatar zaɓar tushen laser da ya dace don injin tsabtace laser ɗinku bisa ga takamaiman buƙatun cire gurɓataccen abu.

▶ Tsaftace Laser na Mopa Pulse

(aiki akan kowane irin kayan aiki)

Laser MOPA shine nau'in tsaftacewar laser da aka fi amfani da shi. MO yana nufin babban oscillator. Tunda ana iya ƙara tsarin laser ɗin fiber MOPA daidai da tushen siginar iri da aka haɗa da tsarin, ba za a canza halayen laser masu dacewa kamar tsayin tsakiya, yanayin bugun jini da faɗin bugun jini ba. Saboda haka, girman daidaitawar sigogi ya fi girma kuma kewayon ya fi faɗi. Ga yanayi daban-daban na aikace-aikace na kayan aiki daban-daban, daidaitawar tagar tsari ta fi ƙarfi kuma tazara ta taga ta fi girma, wanda zai iya dacewa da tsaftace saman kayan aiki daban-daban.

▶ Tsaftace Laser na Fiber Mai Haɗaka

(mafi kyawun zaɓi don cire fenti)

Tsaftace na'urorin Laser masu haɗaka suna amfani da na'urar laser mai ci gaba da semiconductor don samar da fitarwar zafi, ta yadda substrate ɗin da za a tsaftace zai sha makamashi don samar da iskar gas, da kuma gajimare na plasma, sannan ya samar da matsin lamba na faɗaɗa zafi tsakanin kayan ƙarfe da kuma gurɓataccen Layer, wanda ke rage ƙarfin haɗin tsakanin layukan. Lokacin da tushen laser ya samar da hasken laser mai ƙarfi, raƙuman girgiza za su cire haɗin tare da ƙarfin mannewa mai rauni, don cimma tsaftacewar laser cikin sauri.

Tsaftace-tsaftace na Laser yana haɗa ayyukan laser mai ci gaba da bugun zuciya a lokaci guda. Babban gudu, inganci mai girma, da kuma ingantaccen tsaftacewa iri ɗaya, ga kayayyaki daban-daban, kuma ana iya amfani da tsawon tsayi daban-daban na tsaftace laser a lokaci guda don cimma manufar cire tabo.

Misali, a cikin tsaftace laser na kayan shafa mai kauri, fitowar makamashin laser mai yawan bugun jini guda ɗaya yana da yawa kuma farashin yana da yawa. Tsaftacewar haɗakar laser mai pulsed da semiconductor laser na iya inganta ingancin tsaftacewa cikin sauri da inganci, kuma baya haifar da lahani ga substrate. A cikin tsaftace laser na kayan da ke nuna haske kamar ƙarfe na aluminum, laser guda ɗaya yana da wasu matsaloli kamar babban haske. Ta amfani da tsaftacewar laser mai pulse da semiconductor laser composite, ƙarƙashin aikin watsawar zafi ta laser semiconductor, yana ƙara yawan shaƙar makamashi na Layer oxide akan saman ƙarfe, don haka hasken laser na pulse zai iya bare Layer oxide da sauri, inganta ingantaccen cirewa yadda ya kamata, musamman ingancin cire fenti yana ƙaruwa da fiye da sau 2.

▶ Tsaftace Laser na CO2

(mafi kyawun zaɓi don tsaftace kayan da ba ƙarfe ba)

Laser ɗin carbon dioxide wani nau'in laser ne na gas wanda ke da iskar CO2 a matsayin kayan aiki, wanda ke cike da iskar CO2 da sauran iskar gas masu taimako (helium da nitrogen da ƙaramin adadin hydrogen ko xenon). Dangane da tsayin daka na musamman, laser ɗin CO2 shine mafi kyawun zaɓi don tsaftace saman kayan da ba na ƙarfe ba kamar cire manne, shafi da tawada. Misali, amfani da laser ɗin CO2 don cire layin fenti mai haɗawa akan saman aluminum ba ya lalata saman fim ɗin anodic oxide, kuma baya rage kauri.

▶ Tsaftace Laser na UV

(mafi kyawun zaɓi ga na'urar lantarki mai inganci)

Na'urorin laser na ultraviolet da ake amfani da su a cikin na'urar laser micromachining galibi sun haɗa da na'urorin laser na excimer da duk na'urorin laser masu ƙarfi. Tsawon laser na ultraviolet gajere ne, kowane photon guda ɗaya zai iya samar da makamashi mai yawa, zai iya karya alaƙar sinadarai tsakanin kayan kai tsaye. Ta wannan hanyar, ana cire kayan da aka shafa daga saman ta hanyar iskar gas ko barbashi, kuma duk tsarin tsaftacewa yana samar da ƙarancin kuzarin zafi wanda zai shafi ƙaramin yanki akan aikin. Sakamakon haka, tsaftacewar laser na UV yana da fa'idodi na musamman a cikin ƙananan masana'antu, kamar tsaftacewar Si, GaN da sauran kayan semiconductor, quartz, sapphire da sauran lu'ulu'u na gani, And polyimide (PI), polycarbonate (PC) da sauran kayan polymer, na iya inganta ingancin masana'antu yadda ya kamata.

Ana ɗaukar laser na UV a matsayin mafi kyawun tsarin tsaftace laser a fannin kayan lantarki masu inganci, fasahar sarrafa shi mafi kyau "sanyi" ba ta canza halayen zahiri na abu a lokaci guda, ana iya amfani da saman ƙananan injina da sarrafawa sosai a sadarwa, na'urorin gani, sojoji, binciken laifuka, likitanci da sauran masana'antu da fannoni. Misali, zamanin 5G ya haifar da buƙatar kasuwa don sarrafa FPC. Amfani da injin laser na UV yana ba da damar daidaita injinan FPC da sauran kayayyaki masu sanyi.

Lokacin Saƙo: Oktoba-10-2022