Yintoni ukucoca nge-laser

Ngokubeka amandla e-laser aqinileyo kumphezulu wesixhobo esingcolisiweyo, ukucocwa nge-laser kunokususa umaleko wokungcola ngoko nangoko ngaphandle kokonakalisa inkqubo ye-substrate. Lukhetho olufanelekileyo kwisizukulwana esitsha sobuchwepheshe bokucoca imboni.

Itekhnoloji yokucoca nge-laser ikwayeyona teknoloji ibalulekileyo yokucoca kushishino, ekwakheni iinqanawa, kwi-aerospace, nakwezinye iindawo zokuvelisa ezikumgangatho ophezulu, kubandakanya ukususwa kokungcola ngerabha kumphezulu weenkuni zamatayara, ukususwa kwezinto ezingcolisayo zeoyile ye-silicon kumphezulu wefilimu yegolide, kunye nokucoca ngokuchanekileyo okuphezulu kushishino lwe-microelectronics.

Iinkqubo eziqhelekileyo zokucoca nge-laser

◾ Ukususwa kwepeyinti

◾ Ukususwa kweoyile

◾ Ukususwa kweOkside

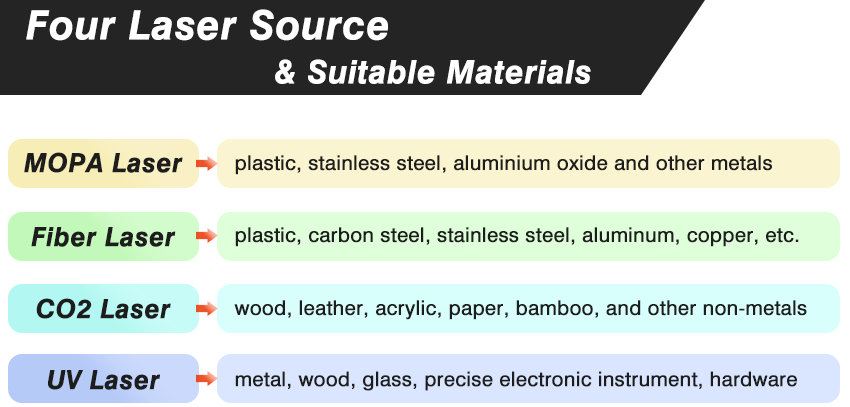

Kwiteknoloji yelaser efana nokusika ilaser, ukukrola ngelaser, ukucocwa ngelaser, kunye nokuwelda ngelaser, usenokuba uqhelene nezi zinto ngaphandle komthombo welaser ohambelanayo. Kukho ifomu yesalathiso sakho emalunga nemithombo yelaser emine kunye nezixhobo ezifanelekileyo kunye nokusetyenziswa.

Umthombo we-laser emine malunga nokucocwa kwe-laser

Ngenxa yokwahluka kwiiparameter ezibalulekileyo ezifana nobude bomda kunye namandla omthombo owahlukileyo we-laser, izinga lokufunxwa kwezinto ezahlukeneyo kunye namabala, ngoko ke kufuneka ukhethe umthombo we-laser ofanelekileyo kumatshini wakho wokucoca i-laser ngokweemfuno ezithile zokususa ungcoliseko.

▶ Ukucoca nge-MOPA Pulse Laser

(ukusebenza kuzo zonke iintlobo zezinto)

I-laser ye-MOPA lolona hlobo lusetyenziswa kakhulu lokucoca nge-laser. I-MO imele i-master oscillator. Ekubeni inkqubo ye-laser ye-fiber ye-MOPA inokwandiswa ngokuhambelana ngqo nomthombo wesignali yembewu edityaniswe nenkqubo, iimpawu ezifanelekileyo ze-laser ezifana nobude be-wavelength ephakathi, i-pulse waveform kunye nobubanzi be-pulse aziyi kutshintshwa. Ke ngoko, ubukhulu bokulungiswa kweparameter buphezulu kwaye uluhlu lubanzi. Kwiimeko ezahlukeneyo zokusetyenziswa kwezinto ezahlukeneyo, ukuguquguquka kunamandla kwaye ixesha le-process window likhulu, elinokufikelela ekucoceni umphezulu wezinto ezahlukeneyo.

▶ Ukucocwa kweLaser yeFiber edityanisiweyo

(ukhetho olufanelekileyo lokususa ipeyinti)

Ukucoca i-laser composite kusebenzisa i-semiconductor continuous laser ukuvelisa umbane oqhuba ubushushu, ukuze i-substrate eza kucocwa ifunxe amandla okuvelisa i-gasification, kunye ne-plasma cloud, kwaye yenze uxinzelelo lokwanda kobushushu phakathi kwezinto zesinyithi kunye nomaleko ongcolisiweyo, kunciphisa amandla okubopha phakathi komaleko. Xa umthombo we-laser uvelisa umqadi we-laser we-pulse onamandla aphezulu, i-vibration shock wave iya kususa isinamathiselo ngamandla okunamathela abuthathaka, ukuze kufezekiswe ukucoca nge-laser ngokukhawuleza.

Ukucoca nge-laser composite kudibanisa imisebenzi ye-laser eqhubekayo kunye ne-pulsed laser ngaxeshanye. Isantya esiphezulu, ukusebenza kakuhle, kunye nomgangatho wokucoca ofanayo, kwizixhobo ezahlukeneyo, kunokusebenzisa ubude obahlukeneyo bokucoca nge-laser ngaxeshanye ukufezekisa injongo yokususa amabala.

Umzekelo, ekucoceni izinto zokugquma ezixineneyo nge-laser, imveliso yamandla e-single laser multi-pulse energy inkulu kwaye ixabiso liphezulu. Ukucocwa okuhlanganisiweyo kwe-pulsed laser kunye ne-semiconductor laser kunokuphucula umgangatho wokucoca ngokukhawuleza nangokufanelekileyo, kwaye akubangeli monakalo kwi-substrate. Ekucoceni nge-laser izinto ezikhanyayo kakhulu ezifana ne-aluminium alloy, i-single laser ineengxaki ezithile ezifana nokukhanya okuphezulu. Ukusebenzisa i-pulse laser kunye ne-semiconductor laser combined cleaning, phantsi kwesenzo se-semiconductor laser thermal conduction transmission, kwandisa izinga lokufunxwa kwamandla kwi-oxide layer kumphezulu wesinyithi, ukuze i-pulse laser beam ikwazi ukuxobula i-oxide layer ngokukhawuleza, iphucule ukusebenza kakuhle kokususa, ngakumbi ukusebenza kakuhle kokususa ipeyinti kunyuswe ngaphezu kwamaxesha amabini.

▶ Ukucoca nge-laser ye-CO2

(ukhetho olungcono lokucoca izinto ezingezizo ezesinyithi)

Ilaser yekhabhoni diokside yilaser yegesi enegesi ye-CO2 njengesixhobo esisebenzayo, ezaliswe yigesi ye-CO2 kunye nezinye iigesi ezincedisayo (i-helium kunye ne-nitrogen kunye nomlinganiselo omncinci we-hydrogen okanye i-xenon). Ngokusekelwe kubude bayo obukhethekileyo, ilaser ye-CO2 yeyona ndlela ilungileyo yokucoca umphezulu wezinto ezingezizo zesinyithi ezifana nokususa iglu, i-coating kunye ne-inki. Umzekelo, ukusetyenziswa kwelaser ye-CO2 ukususa umaleko wepeyinti edibeneyo kumphezulu we-aluminium alloy akuwonakalisi umphezulu wefilimu ye-anodic oxide, kwaye akunciphisi ubukhulu bayo.

▶ Ukucoca ngeLaser ye-UV

(ukhetho olungcono kwizixhobo ze-elektroniki ezintsonkothileyo)

Iilaser ze-Ultraviolet ezisetyenziswa kwi-laser micromachining ziquka ikakhulu iilaser ze-excimer kunye nazo zonke iilaser ze-solid-state. Ububanzi be-laser ye-Ultraviolet bufutshane, i-photon nganye inokunika amandla aphezulu, inokuphula ngokuthe ngqo iibhondi zeekhemikhali phakathi kwezinto. Ngale ndlela, izinto ezigqunyiweyo zisuswa kumphezulu ngendlela yegesi okanye amasuntswana, kwaye yonke inkqubo yokucoca ivelisa amandla obushushu aphantsi aza kuchaphazela kuphela indawo encinci kwindawo yokusebenza. Ngenxa yoko, ukucoca i-UV laser kuneengenelo ezikhethekileyo kwimveliso emincinci, njengokucoca i-Si, i-GaN kunye nezinye izinto ze-semiconductor, i-quartz, i-sapphire kunye nezinye iikristale ze-optical, kunye ne-polyimide (PI), i-polycarbonate (PC) kunye nezinye izinto ze-polymer, zinokuphucula ngempumelelo umgangatho wokuvelisa.

I-laser ye-UV ithathwa njengeyona ndlela ilungileyo yokucoca i-laser kwicandelo le-elektroniki echanekileyo, eyona ndlela ibalaseleyo yokucubungula "ibandayo" ayitshintshi iipropati zomzimba zento ngaxeshanye, umphezulu womatshini omncinci kunye nokucubungula, ingasetyenziswa kakhulu kunxibelelwano, i-optics, umkhosi, uphando lolwaphulo-mthetho, amashishini kunye neminye imimandla yezonyango. Umzekelo, ixesha le-5G lidale imfuno yemarike yokucubungula i-FPC. Ukusetyenziswa komatshini we-laser ye-UV kwenza kube nokwenzeka ukwenza i-FPC kunye nezinye izinto ngokuchanekileyo.

Ixesha lokuthumela: Okthobha-10-2022