China Die Board Cutting Machine Factories - CO2 Laser Cutting Machine for Thick Acrylic (10mm, 20mm, 30mm) – MimoWork Laser

China Die Board Cutting Machine Factories - CO2 Laser Cutting Machine for Thick Acrylic (10mm, 20mm, 30mm) – MimoWork Laser Detail:

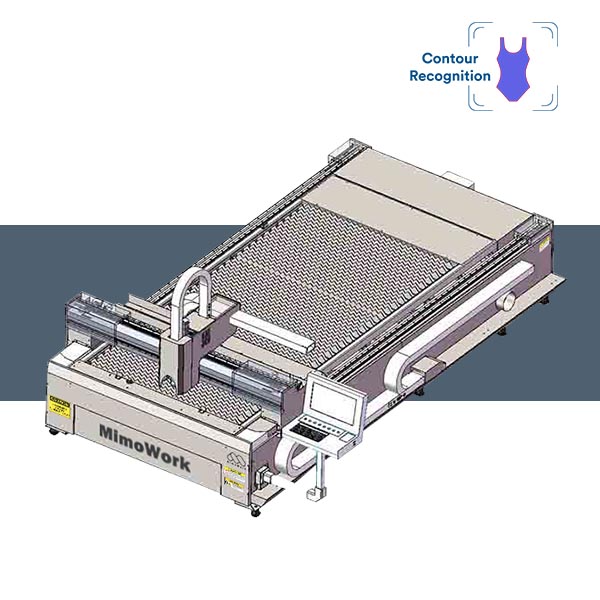

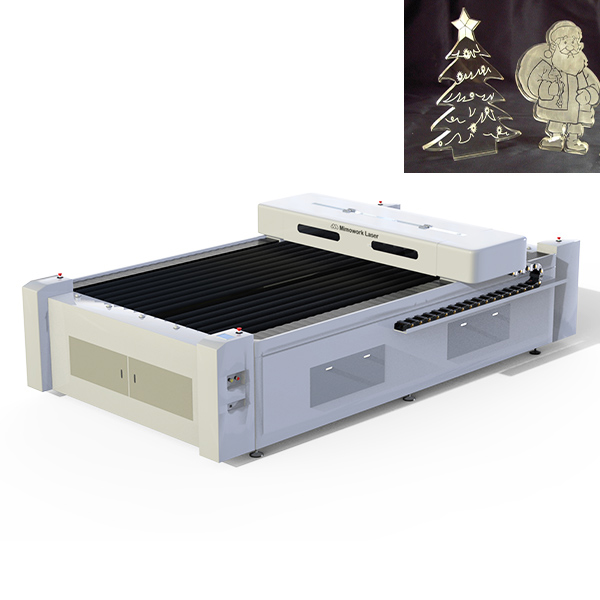

▶ Acrylic Sheet Laser Cutting Machine

Technical Data

|

Working Area (W * L) |

1300mm * 2500mm (51” * 98.4”) |

|

Software |

Offline Software |

|

Laser Power |

150W/300W/500W |

|

Laser Source |

CO2 Glass Laser Tube |

|

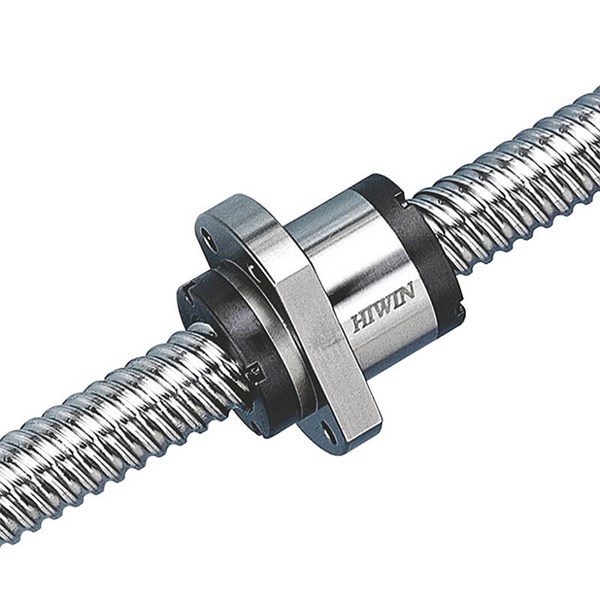

Mechanical Control System |

Ball Screw & Servo Motor Drive |

|

Working Table |

Knife Blade or Honeycomb Working Table |

|

Max Speed |

1~600mm/s |

|

Acceleration Speed |

1000~3000mm/s2 |

|

Position Accuracy |

≤±0.05mm |

|

Machine Size |

3800 * 1960 * 1210mm |

|

Operating Voltage |

AC110-220V±10%,50-60HZ |

|

Cooling Mode |

Water Cooling and Protection System |

|

Working Environment |

Temperature:0—45℃ Humidity:5%—95% |

|

Package Size |

3850 * 2050 *1270mm |

|

Weight |

1000kg |

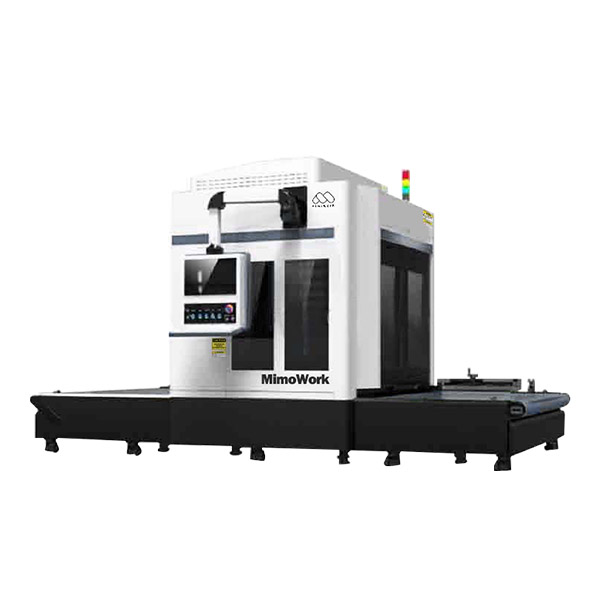

▷ Features of 1325 Laser Cutter

A Giant Leap in Productivity

◾ Stable & excellent cutting quality

◾ High efficiency and precision

◾ Durable and long service life

◾ High speed processing

DIY Your Acrylic Laser Cut Projects

How Thick can a CO2 Laser Cut Acrylic?

The cutting capability of an acrylic engraving machine depends on the rated wattage of its CO2 laser tube.

For instance, a machine equipped with a 40W laser can efficiently cut through acrylic up to 1/8″ (3mm)in thickness, while a more powerful 150W laser cutter for acrylic can handle thicker materials, cutting through acrylic that’s as thick as 5/8″(16mm). The wattage of the laser tube directly affects the machine’s cutting capacity. MimoWork Laser also offers 300-watt, 450-watt, and 600-watt CO2 lasers for cutting acrylic that is more than 20mm thick.

Laser Cutting Acrylic: Suitable Working Table

For achieving optimal results when cutting extruded acrylic, it’s essential to elevate the material slightly above the cutting table’s surface. This practice significantly reduces issues like backside reflection and the appearance of grid marks on the acrylic after laser cutting.

Acrylic Finishing of Laser Cutting

<a href="https://www.mimowork.com/laser-cutting-acrylic/" title=">> Learn more acrylic cutting” target=”_blank”>

>> Learn more acrylic cutting

(acrylic laser cut earrings, acrylic laser cut signs, acrylic laser cut jewellery, acrylic laser cut letters…)

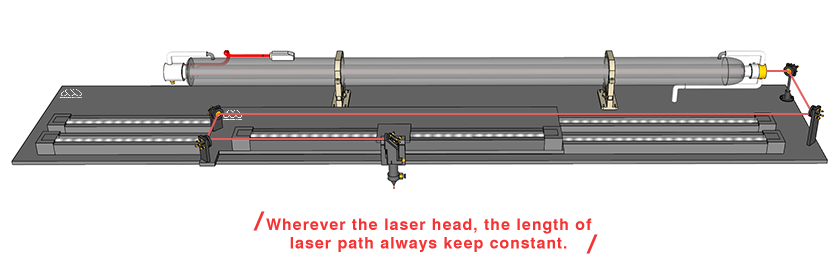

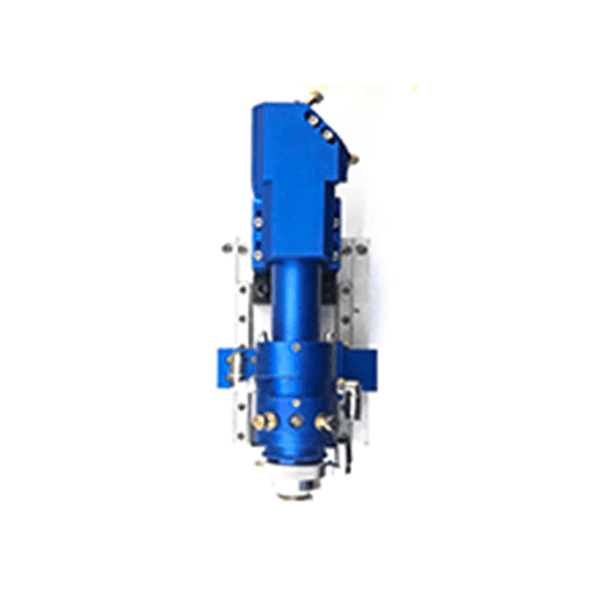

Upgrade Laser Options for you to choose

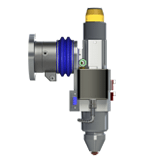

Auto Focus

It is mainly used for metal cutting. You may need to set a certain focus distance in the software when the cutting material is not flat or with different thicknesses. Then the laser head will automatically go up and down, keeping the same height & focus distance to match with what you set inside the software to achieve a consistently high cutting quality.

CCD Camera

The CCD Camera can recognize and position the pattern on the printed acrylic, assisting laser cutter to realize accurate cutting with high quality. Any customized graphic design printed can be flexibly processed along the outline with the optical system, playing an important part in advertising and other industry.

Related Acrylic Laser Cutter

for acrylic and wood laser cutting

<a href="https://www.mimowork.com/flatbed-laser-cutting-machine/laser-engraving-machine-for-acrylic.html" title="Flatbed Laser Cutter 130” target=”_blank”>

Flatbed Laser Cutter 130

• Fast & precise engraving for solid materials

• Two-way penetration design allows ultra-long materials placed and cut

for acrylic and wood laser engraving

<a href="https://www.mimowork.com/flatbed-laser-cutting-machine/desktop-laser-engraver-70.html" title="Desktop Laser Engraver 70” target=”_blank”>

Desktop Laser Engraver 70

• Light and compact design

• Easy to operate for beginners

We’ve designed laser systems for dozens of clients

Seek best acrylic laser cutting machine!

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of China Die Board Cutting Machine Factories - CO2 Laser Cutting Machine for Thick Acrylic (10mm, 20mm, 30mm) – MimoWork Laser , The product will supply to all over the world, such as: Iceland , Gabon , Poland , Our company is continuing to serve customers with high quality, competitive price and timely delivery. We sincerely welcome friends from all over the world to cooperate with us and enlarge our business. If you are interested in our products, please feel free to contact us. We would love to provide you with further information.

Speaking of this cooperation with the Chinese manufacturer, I just want to saywell dodne, we are very satisfied.