Laser Cut Fabric

Fabrics (Textiles) Laser Cutter

The Future of Laser Cutting Fabric

Fabric laser cutting machines have quickly become a game changer in the fabric and textile industries. Whether it’s for fashion, functional clothing, automotive textiles, aviation carpets, soft signage, or home textiles, these machines are revolutionizing the way we cut and prepare fabric.

So, why are both big manufacturers and fresh startups opting for laser cutters instead of sticking with traditional methods? What’s the secret sauce behind the effectiveness of laser cutting and engraving fabric? And, perhaps the most exciting question, what benefits can you unlock by investing in one of these machines?

Let’s dive in and explore!

What is a Fabric Laser Cutter

Combined with the CNC system(Computer Numerical Control) and advanced laser technology, the fabric laser cutter is given outstanding advantages, it can achieve automatic processing and precise & fast & clean laser cutting and tangible laser engraving on various fabrics.

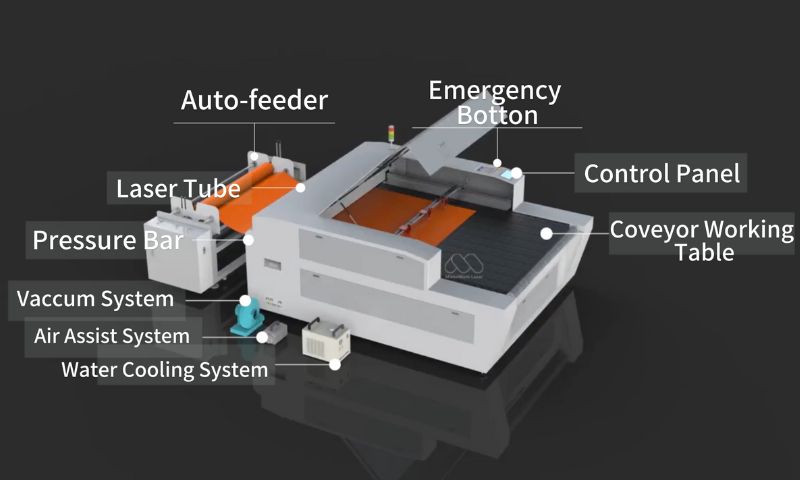

◼ Brief Intro - Laser Fabric Cutter Structure

With high automation, one person is good enough to cope with consistent fabric laser cutting work. Plus with a stable laser machine structure and long service time of laser tube (that can produce co2 laser beam), the fabric laser cutters can get you a long-term profit.

▶ Video Demonstration - Laser Cut Fabric

In the video, we used the laser cutter for cloth 160 with an extension table to cut a roll of canvas fabric. Equipped with the auto-feeder and conveyor table, the whole feeding and conveying workflow is automatic, accurate, and highly efficient. Plus with the dual laser heads, the laser cutting fabric is faster and enables mass production for apparel and accessories in a very short period. Check out the finished pieces, you can find the cutting edge is clean and smooth, the cutting pattern is accurate and precise. So customization in fashion and garment is possible with our professional fabric laser cutting machine.

• Laser Power: 100W / 150W / 300W

• Working Area (W *L): 1600mm * 1000mm (62.9” * 39.3 ”)

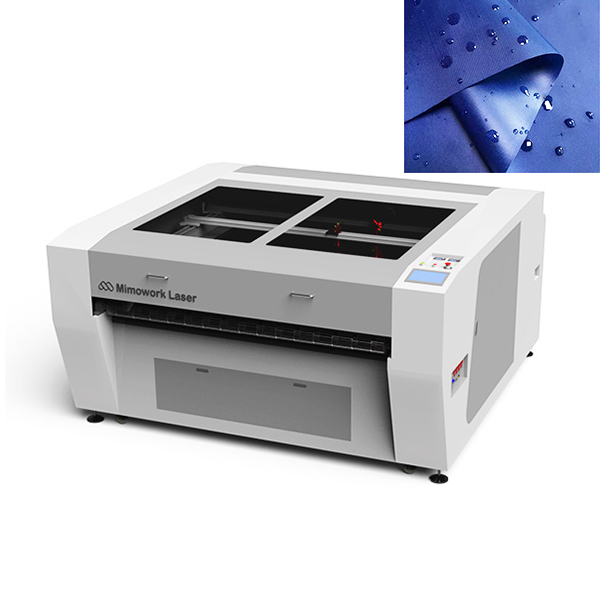

If you’re in the business of apparel, leather shoes, bags, home textiles, or upholstery, investing in a Fabric Laser Cut Machine 160 is a fantastic decision. With a generous working size of 1600mm by 1000mm, it's perfect for handling most roll fabrics.

Thanks to its auto-feeder and conveyor table, this machine makes cutting and engraving a breeze. Whether you’re working with cotton, canvas, nylon, silk, fleece, felt, film, foam, or more, it’s versatile enough to tackle a wide range of materials. This machine could be just what you need to elevate your production game!

• Laser Power: 150W / 300W/ 450W

• Working Area (W * L): 1800mm * 1000mm (70.9” * 39.3 ”)

• Collection Area (W * L): 1800mm * 500mm (70.9” * 19.7'')

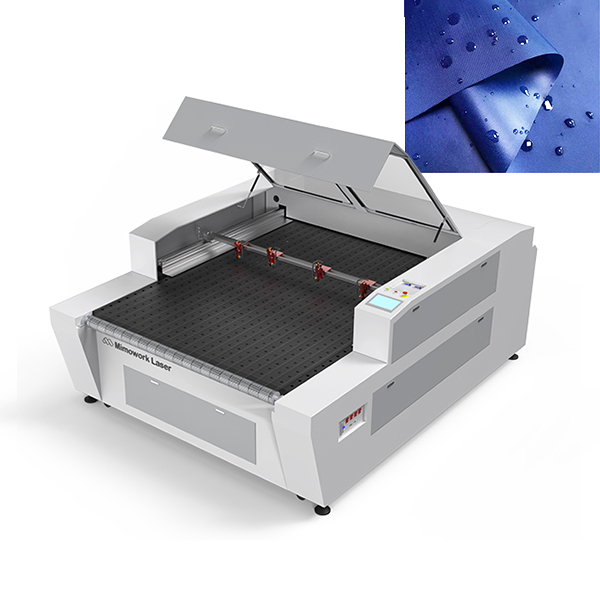

To accommodate a wider range of cutting needs for various fabric sizes, MimoWork has expanded its laser cutting machine to an impressive 1800mm by 1000mm. With the addition of a conveyor table, you can seamlessly feed roll fabrics and leather for uninterrupted laser cutting, perfect for fashion and textiles.

Plus, the option for multiple laser heads boosts your throughput and efficiency. With automatic cutting and upgraded laser heads, you’ll be able to respond swiftly to market demands, setting yourself apart and impressing customers with top-notch fabric quality. This is your chance to elevate your business and make a lasting impression!

• Laser Power: 150W / 300W/ 450W

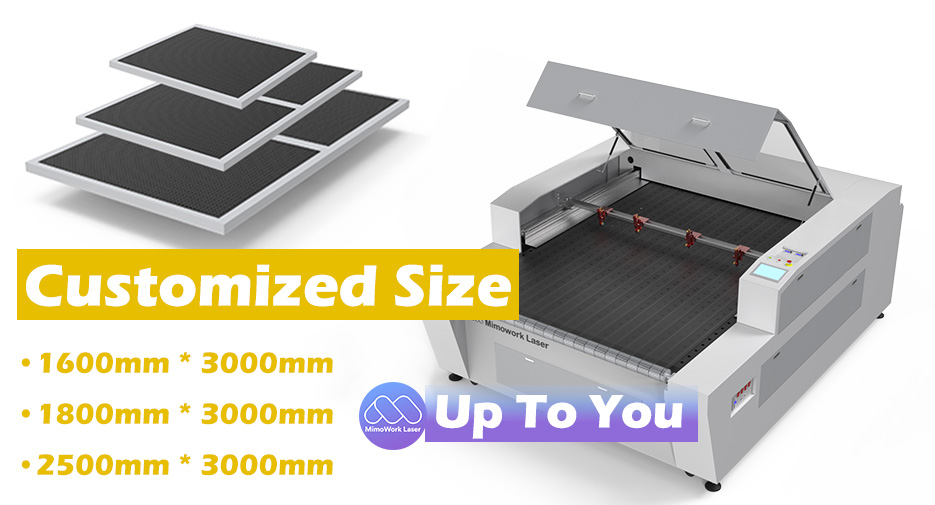

• Working Area (W *L): 1600mm * 3000mm (62.9’’ * 118’’)

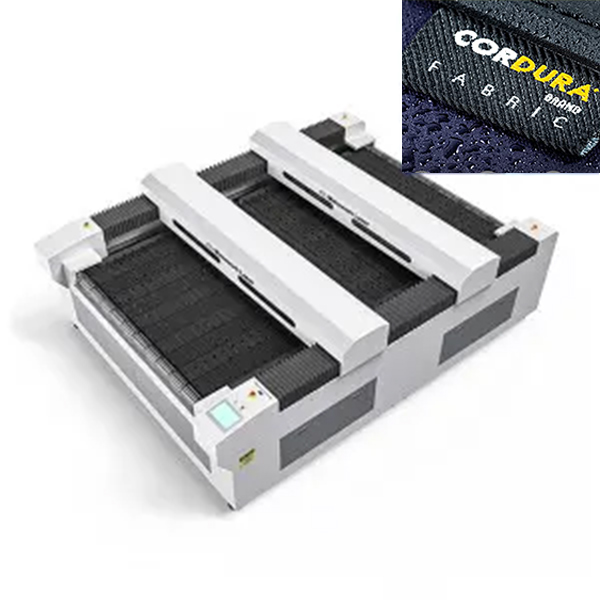

The industrial fabric laser cutter is designed to meet the highest production standards, delivering both exceptional output and outstanding cutting quality. It can easily handle not just regular fabrics like cotton, denim, felt, EVA, and linen, but also tougher industrial and composite materials such as Cordura, GORE-TEX, Kevlar, aramid, insulation materials, fiberglass, and spacer fabric.

With higher power capabilities, this machine can cut through thicker materials like 1050D Cordura and Kevlar with ease. Plus, it features a spacious conveyor table measuring 1600mm by 3000mm, allowing you to tackle larger patterns for fabric or leather projects. This is your go-to solution for high-quality, efficient cutting!

What You Can Do with a Laser Fabric Cutter?

◼ Various Fabrics You Can Laser Cut

"The CO2 Laser Cutter is a fantastic option for working with a wide range of fabrics and textiles. It delivers clean, smooth cutting edges with impressive precision, making it suitable for everything from lightweight materials like organza and silk to heavier fabrics like canvas, nylon, Cordura, and Kevlar. Whether you're cutting natural or synthetic fabrics, this machine consistently produces great results.

But that's not all! This versatile fabric laser cutting machine excels not just at cutting but also at creating beautiful, textured engravings. By adjusting various laser parameters, you can achieve intricate designs, including brand logos, letters, and patterns. This adds a unique touch to your fabrics and boosts brand recognition, making your products truly stand out!"

Video Overview - Laser Cutting Fabrics

Laser Cutting Cotton

Laser Cutting Cordura

Laser Cutting Denim

Laser Cutting Foam

Laser Cutting Plush

Laser Cutting Brushed Fabric

Didn't Find What you Like about Laser Cutting Fabric?

Why not Check out Our YouTube Channel?

◼ A Wide Range of Applications of Laser Cutting Fabric

Investing in a professional fabric laser cutting machine unlocks a wealth of profitable opportunities across various fabric applications. With its exceptional material compatibility and precision cutting capabilities, laser cutting is indispensable in industries like garments, fashion, outdoor gear, insulation materials, filter cloth, car seat covers, and more.

Whether you’re looking to expand your existing business or transform your fabric operations, a fabric laser cutting machine is your reliable partner for achieving both efficiency and high quality. Embrace the future of fabric cutting and watch your business thrive!

What Fabric Application would be Your Production?

Laser Would be the Perfect Fit!

Advantages of Laser Cutting Fabric

Synthetic fabrics and natural fabrics can be laser cut with high precision and high quality. By heat melting the fabric edges, the fabric laser cutting machine can bring you an excellent cutting effect with a clean & smooth edge. Also, no fabric distortion occurs thanks to contactless laser cutting.

◼ Why You Should Choose Fabric Laser Cutter?

Clean & Smooth edge

Flexible Shape Cutting

Fine Pattern Engraving

✔ Perfect Cutting Quality

✔ High Production Efficiency

✔ Versatility & Flexibility

◼ Added Value from Mimo Laser Cutter

✦ 2/4/6 laser heads can be upgraded to increase efficiency.

✦ Extensible Working Table helps save pieces collecting time.

✦ Fewer materials waste and optimal layout thanks to Nesting Software.

✦ Continuously feeding & cutting due to Auto-Feeder and Conveyor Table.

✦ Laser working tables can be customized according to your material sizes and types.

✦ Printed fabrics can be precisely cut along the contour with a Camera Recognition System.

✦ The customized laser system and auto-feeder make laser cutting multi-layer fabrics possible.

Upgrade Your Productivity with A Professional Fabric Laser Cutter!

How to Laser Cut Fabric?

◼ Easy Operation of Laser Cutting Fabric

The fabric laser cutting machine is an excellent choice for both customized and mass production, thanks to its high precision and efficiency. Unlike traditional knife cutters or scissors, the fabric laser cutter uses a non-contact processing method. This gentle approach is particularly friendly to most fabrics and textiles, ensuring clean cuts and beautifully detailed engravings without damaging the material. Whether you’re creating unique designs or scaling up production, this technology meets your needs with ease!

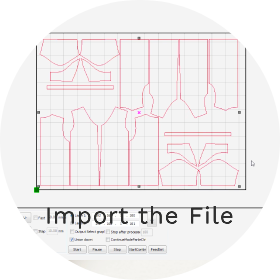

With the help of the digital control system, the laser beam is directed to cut through fabrics and leather. Typically, roll fabrics are placed on the auto-feeder and automatically transported on the conveyor table. The built-in software ensures precise control of the laser head's positioning, allowing for accurate fabric laser cutting based on the cutting file. You can use the fabric laser cutter and engraver to deal with most textiles and fabrics like cotton, denim, Cordura, Kevlar, nylon, etc.

Video Demo - Automatic Laser Cutting For Fabric

Keywords

• laser cutting cloth

• laser cutting textile

• laser engraving fabric

Any questions about how laser works?

What Our Clients Say?

A Client Working with Sublimation Fabric, Said:

From a Client Making Cornhole Bags, Said:

Questions about Laser Cutting Fabric, Textile, Cloth?

For Cutting Fabric

CNC VS Laser Cutter: Which One is Better?

◼ CNC VS. Laser for Cutting Fabric

◼ Who Should Choose Fabric Laser Cutters?

Now, let’s talk about the real question, who should consider investing in a laser cutting machine for fabric? I've compiled a list of five types of businesses worth considering for laser production. See if you're one of them.

Is the Laser a Perfect Fit for Your Production & Business?

Our Laser Experts are On Standby!

When we say fabric laser cutting machine, we are not simply talking about a laser cutting machine that can cut fabric, we mean the laser cutter that comes with a conveyor belt, auto feeder and all other components to help you cut fabric from roll automatically.

Compared with investing in a regular table-size CO2 laser engraver that’s mainly used for cutting solid materials, such as Acrylic and Wood, you need to choose a textile laser cutter more wisely. There are some common questions from fabric manufacturers.

• Can You Laser Cut Fabric?

• What is the Best Laser for Cutting Fabric?

• What Fabrics are Safe for Laser Cutting?

• Can you Laser Engrave Fabric?

• Can you Laser Cut Fabric without Fraying?

• How to Straighten Fabric Before Cutting?

Don't worry if you use a fabric laser cutter to cut the fabric. There are two designs that always enable the fabric to keep even and straight whether during conveying the fabric or cutting the fabric. Auto-feeder and conveyor table can automatically transmit the material to the right position without any offset. And the vacuum table and exhaust fan render the fabric fixed and flat on the table. You will get high-quality cutting quality by laser cutting fabric.

Yes! Our fabric laser cutter can be equipped with a camera system that is able to detect the printed and sublimation pattern, and direct the laser head to cut along the contour. That's user-friendly and intelligent for laser cutting leggings and other printed fabrics.

It's easy and intelligent! We have the specialized Mimo-Cut (and Mimo-Engrave) laser software where you can flexibly set the proper parameters. Usually, you need to set the laser speed and laser power. Thicker fabric means higher power. Our laser technician will give a specialized & all-around laser guide based on your requirements.

Ready to Boost your Production & Business with Us?

— Videos Display —

Advanced Laser Cut Fabric Technology

1. Auto Nesting Software for Laser Cutting

2. Extension Table Laser Cutter - Easy & Time-Saving

3. Laser Engraving Fabric - Alcantara

4. Camera Laser Cutter for Sportswear & Clothing

Learn more about the technology of laser cutting fabrics and textiles, check out the page: Automated Fabric Laser Cutting Technology >

Want to See Demos of Your Production & Business?

Professional Laser Cutting Solution for Fabrics (Textiles)

As new fabrics with unique functions and advanced textile technologies emerge, there's a growing need for more efficient and flexible cutting methods. Laser cutters really shine in this area, offering high precision and customization. They're widely used for home textiles, garments, composite materials, and even industrial fabrics.

One of the best things about laser cutting is that it’s contactless and thermal, which means your materials stay intact and undamaged, with clean edges that don’t require any post-trimming.

But it’s not just about cutting! Laser machines are also fantastic for engraving and perforating fabrics. MimoWork is here to provide you with top-notch laser solutions to meet all your needs!

Related Fabrics of Laser Cutting

Laser cutting plays an important role in cutting natural and synthetic fabrics. With wide materials compatibility, natural fabrics like silk, cotton, linen cloth can be laser cut meanwhile retaining themselves non-damaged in intactness and properties. Besides that, the laser cutter featuring contactless processing solves a troublesome problem from stretched fabrics - fabrics distortion. Excellent advantages make laser machines popular and the preferred choice for clothing, accessories, and industrial fabrics. No contamination and force-free cutting protect material functions, as well as create crispy and clean edges due to thermal treatment. In the automotive interior, home textiles, filter media, clothing, and outdoor equipment, laser cutting is active and creates more possibilities in the whole workflow.

MimoWork - Laser Cutting Clothing (Shirt, Blouse, Dress)

MimoWork - Textile Laser Cutting Machine with Ink-Jet

MimoWork - How to Choose Laser Fabric Cutter

MimoWork - Laser Cutting Filtration Fabric

MimoWork - Ultra Long Laser Cutting Machine for Fabric

More videos about fabric laser cutting are continually updated on our Youtube Channel. Subscribe to us and follow the newest ideas about laser cutting and engraving.