Idan kai sabon shiga ne a fasahar Laser kuma ka yi la'akari da siyan injin yanke laser, dole ne a sami tambayoyi da yawa da kake son yi.

MimoWorkIna farin cikin raba muku ƙarin bayani game da injunan laser na CO2 kuma da fatan za ku iya samun na'urar da ta dace da ku, ko daga gare mu ne ko kuma daga wani mai samar da laser.

A cikin wannan labarin, za mu bayar da taƙaitaccen bayani game da tsarin injin a cikin babban tsari kuma mu yi nazarin kwatancen kowane fanni. Gabaɗaya, labarin zai rufe batutuwan kamar haka:

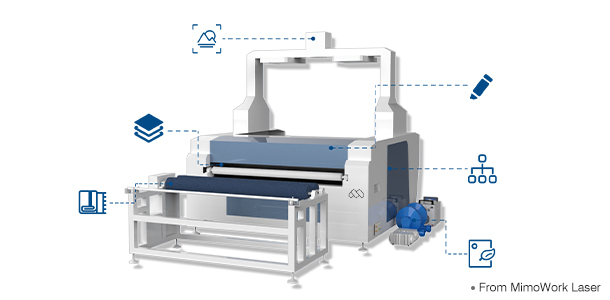

Injinan injin Laser na CO2

a. Motar DC mara gogewa, Motar Servo, Motar Mataki

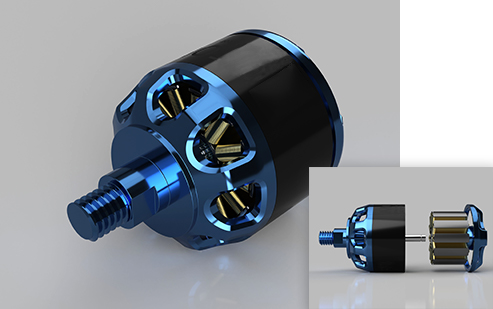

Motar DC mara gogewa (kai tsaye)

Motar DC mara gogewa na iya aiki a babban RPM (juyin juya hali a minti daya). Stator na motar DC yana samar da filin maganadisu mai juyawa wanda ke tura armature don juyawa. Daga cikin dukkan injinan, motar dc mara gogewa na iya samar da makamashin motsi mafi karfi da kuma tuƙa kan laser don motsawa cikin sauri mai girma.Mafi kyawun injin sassaka laser na CO2 na MimoWork yana da injin buroshi mara gogewa kuma yana iya kaiwa matsakaicin saurin sassaka na 2000mm/s.Ba kasafai ake ganin injin dc mara gogewa a cikin injin yanke laser na CO2 ba. Wannan saboda saurin yankewa abu yana iyakance ne da kauri kayan. Akasin haka, ƙaramin ƙarfi ne kawai kake buƙata don sassaka zane-zane akan kayanka. Injin mara gogewa wanda aka sanya masa mai sassaka laser zai yi aiki.rage lokacin sassaka da daidaito mafi girma.

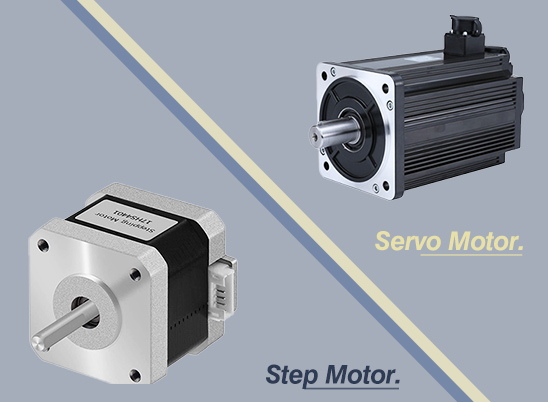

Motar Servo & Motar Mataki

Idan aka haɗa shi da teburin sassaka laser na CO2, injinan servo suna ba da ƙarfin juyi da daidaito mafi girma, musamman ga ayyukan fasaha kamar yanke zane mai tacewa ko murfin rufi. Duk da cewa suna da tsada sosai kuma suna buƙatar na'urori masu ɓoyewa da akwatin gearbox - suna sa saitin ya zama mai rikitarwa - sun dace da aikace-aikace masu wahala. Duk da haka, idan kuna yin kyautai na sana'a ko alamun hannu, injin stepper akan teburin sassaka laser ɗinku yawanci yana yin aikin da kyau.

Kowace mota tana da fa'idodi da rashin amfaninta. Wanda ya dace da kai shine mafi dacewa da kai.

Hakika, MimoWork na iya samar daMai sassaka da kuma abin yanka Laser CO2 tare da nau'ikan injin guda ukubisa ga buƙatarku da kasafin kuɗin ku.

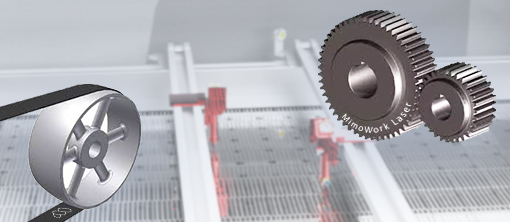

b. Na'urar Belt da Gear Drive

Na'urar bel tana amfani da bel don haɗa ƙafafun, yayin da na'urar gear ke haɗa gears kai tsaye ta cikin haƙoran da ke haɗe. A cikin na'urorin laser, duka tsarin suna taimakawa wajen motsa gantry kuma suna shafar yadda na'urar za ta iya zama daidai.

Bari mu kwatanta su biyun da wannan tebur:

| Belt Drive | Na'urar Gear |

| Babban abu Pulleys da Belt | Babban kayan Gears |

| Ana buƙatar ƙarin sarari | Ana buƙatar ƙasa da sarari, saboda haka ana iya tsara injin laser don ya zama ƙarami |

| Babban asarar gogayya, saboda haka ƙarancin watsawa da ƙarancin inganci | Ƙarancin asarar gogayya, saboda haka watsawa mafi girma da kuma ƙarin inganci |

| Rage tsawon rai fiye da na'urorin gear, yawanci yana canzawa duk bayan shekaru 3 | Tsawon rai ya fi girma fiye da na'urorin bel, yawanci yakan canza kowace shekara goma |

| Yana buƙatar ƙarin gyara, amma farashin gyara yana da rahusa kuma yana da daɗi | Yana buƙatar ƙarancin kulawa, amma farashin kulawa ya fi tsada kuma yana da wahala |

| Ba a buƙatar shafa man shafawa ba | Ana buƙatar shafa man shafawa akai-akai |

| Yana aiki cikin shiru sosai | Ana ƙara hayaniya a aiki |

An ƙera tsarin injin ɗin yankan gear da bel ɗin duka a cikin injin yanke laser tare da fa'idodi da rashin amfani. A taƙaice dai,Tsarin tuƙi na bel ya fi fa'ida a cikin ƙananan nau'ikan injuna masu tashi-da-ganisaboda mafi girman watsawa da dorewa,Na'urar gear ta fi dacewa da babban tsarin yanke laser, yawanci tare da ƙirar gani mai haɗaka.

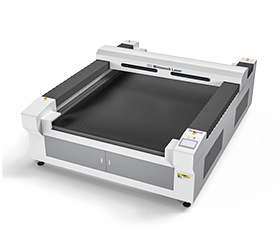

c. Teburin Aiki na Tsafta VS Teburin Aiki na Mai Na'urar Ginawa

Domin inganta sarrafa laser, kuna buƙatar fiye da ingantaccen kayan laser da ingantaccen tsarin tuƙi don motsa kan laser, ana kuma buƙatar teburin tallafi mai dacewa. Teburin aiki wanda aka tsara don dacewa da kayan ko aikace-aikacen yana nufin zaku iya haɓaka ƙarfin injin laser ɗinku.

Gabaɗaya, akwai nau'ikan dandamali guda biyu na aiki: Na'urar aiki da ta hannu.

(Don amfani daban-daban, zaka iya amfani da duk wani nau'in kayan aiki, ko daikayan takarda ko kayan da aka naɗe)

○Teburin Aiki Mai Sauƙiya dace don sanya kayan takarda kamar acrylic, itace, takarda (kwali).

• teburin tsiri mai wuka

• teburin tsefe zuma

○Teburin Aiki na Mai jigilar kayaya dace da sanya kayan birgima kamar yadi, fata, kumfa.

• teburin jigilar kaya

• teburin jigilar kaya

Amfanin tsarin teburin aiki mai dacewa

✔Kyakkyawan fitar da hayakin da aka yanke

✔Daidaita kayan, babu wani motsi da ke faruwa lokacin yankewa

✔Dace da lodawa da sauke kayan aikin

✔Jagorar mayar da hankali mafi kyau godiya ga saman da aka shimfiɗa

✔Sauƙin kulawa da tsaftacewa

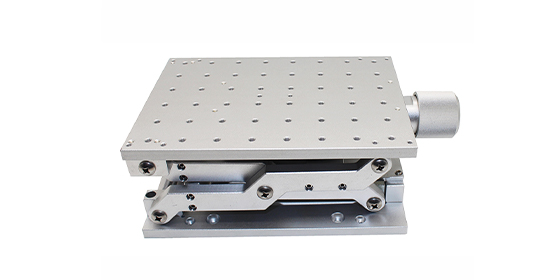

d. Dandalin Ɗagawa ta atomatik VS Dandalin Ɗagawa da hannu

Lokacin da ake zana kayan da aka yi da itace, kamaracrylic (PMMA)kumaitace (MDF), kayan sun bambanta a kauriTsayin da ya dace na iya inganta tasirin sassaka. Ana buƙatar dandamalin aiki mai daidaitawa don nemo mafi ƙarancin wurin mayar da hankali. Ga injin sassaka laser CO2, ana kwatanta dandamalin ɗagawa ta atomatik da na ɗagawa da hannu akai-akai. Idan kasafin kuɗin ku ya isa, ku zaɓi dandamalin ɗagawa ta atomatik.Ba wai kawai inganta daidaiton yankewa da sassaka ba, har ma yana iya ceton ku da yawa lokaci da ƙoƙari.

e. Tsarin Samun Iska a Sama, Gefe da Ƙasa

Tsarin iska na ƙasa shine zaɓi mafi yawan amfani da na'urar laser CO2, amma MimoWork kuma yana da wasu nau'ikan ƙira don haɓaka ƙwarewar sarrafa laser gaba ɗaya.babban injin yanke laser, MimoWork zai yi amfani da haɗintsarin gajiyarwa na sama da ƙasadon haɓaka tasirin cirewa yayin da ake ci gaba da samun sakamako mai inganci na yanke laser. Ga mafi yawan muinjin alama na galvo, za mu shigar datsarin samun iska na gefedon fitar da hayakin. Duk bayanan da ke cikin injin ya kamata a yi su da kyau don magance matsalolin kowace masana'antu.

An tsarin cirewaAna samar da shi ne a ƙarƙashin kayan da ake ƙera. Ba wai kawai ana fitar da hayakin da maganin zafi ke samarwa ba, har ma ana daidaita kayan, musamman masaka mai sauƙi. Girman ɓangaren saman sarrafawa wanda kayan da ake sarrafawa ke rufewa, mafi girman tasirin tsotsa da kuma injin tsotsa da ke haifarwa.

Shagunan Laser na gilashin CO2 VS Shagunan Laser na CO2 RF

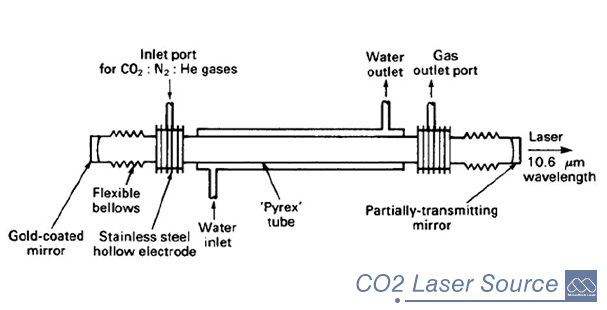

a. Ka'idar motsa jiki ta laser CO2

Laser ɗin carbon dioxide yana ɗaya daga cikin lasers ɗin gas na farko da aka ƙirƙira. Tare da shekaru da yawa na ci gaba, wannan fasaha ta tsufa sosai kuma ta isa ga aikace-aikace da yawa. Bututun laser na CO2 yana motsa laser ta hanyar ƙa'idarfitar da haskekumayana canza makamashin lantarki zuwa makamashin haske mai ƙarfiTa hanyar amfani da babban ƙarfin lantarki akan carbon dioxide (matsayin laser mai aiki) da sauran iskar gas a cikin bututun laser, iskar tana samar da fitar haske kuma tana ci gaba da motsawa a cikin akwati tsakanin madubin haske inda madubai suke a ɓangarorin biyu na jirgin don samar da laser.

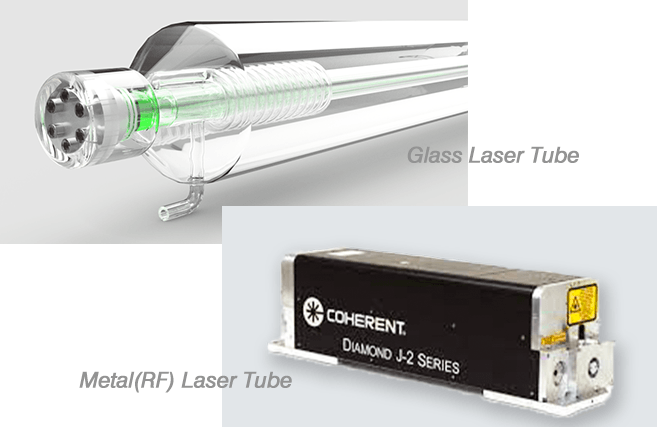

b. Bambancin bututun laser na gilashin CO2 da bututun laser na CO2 RF

Idan kana son ƙarin fahimtar na'urar Laser ta CO2, dole ne ka zurfafa cikin cikakkun bayanai game da na'urar.tushen laserA matsayin nau'in laser mafi dacewa don sarrafa kayan da ba na ƙarfe ba, tushen laser CO2 za a iya raba shi zuwa manyan fasahohi guda biyu:Gilashin Laser TubekumaTube na Laser na ƙarfe RF.

(Af, babban ƙarfin laser mai sauri-axial-flow CO2 da kuma jinkirin-axial flow CO2 laser ba su cikin tattaunawarmu ta yau)

| Gilashin (DC) Bututun Laser | Bututun Laser na Karfe (RF) | |

| Tsawon rai | Awanni 2500-3500 | awanni 20,000 |

| Alamar kasuwanci | 'Yan China | Mai jituwa |

| Hanyar Sanyaya | Ruwan sanyi | Ruwan sanyi |

| Ana iya caji | A'a, amfani sau ɗaya kawai | Ee |

| Garanti | Watanni 6 | Watanni 12 |

Tsarin Kulawa da Software

Manhajar injin yanke laser ta CO2 tana aiki a matsayin kwakwalwar tsarin, tana amfani da shirye-shiryen CNC don jagorantar motsin laser da daidaita matakan wutar lantarki. Yana ba da damar samar da sassauƙa ta hanyar barin ku canza ƙira da sauri da kuma sarrafa kayayyaki daban-daban - kawai ta hanyar daidaita ƙarfin laser da saurin yankewa, babu buƙatar canza kayan aiki.

Mutane da yawa a kasuwa za su kwatanta fasahar software ta China da fasahar software ta kamfanonin laser na Turai da Amurka. Don kawai yankewa da sassaka tsari, algorithms na yawancin software a kasuwa ba su da bambanci sosai. Tare da shekaru da yawa na ra'ayoyin bayanai daga masana'antun da yawa, software ɗinmu yana da waɗannan fasaloli:

1. Mai sauƙin amfani

2. Aiki mai dorewa da aminci a cikin dogon lokaci

3. Kimanta lokacin samarwa yadda ya kamata

4. Tallafawa DXF, AI, PLT da sauran fayiloli da yawa

5. Shigo da fayiloli da yawa na yankewa a lokaci guda tare da damar gyara

6. Shirya tsarin yankewa ta atomatik tare da jeri na ginshiƙai da layuka tare daMimo-Nest

Baya ga tushen manhajar yankewa ta yau da kullun,Tsarin Gane Ganewar Hankalizai iya inganta matakin sarrafa kansa a cikin samarwa, rage aiki da inganta daidaiton yankewa. A taƙaice, Kyamarar CCD ko Kyamarar HD da aka sanya akan injin laser na CO2 tana aiki kamar idanun ɗan adam kuma tana ba da umarni ga injin laser inda za a yanke. Ana amfani da wannan fasaha sosai a aikace-aikacen bugawa na dijital da filayen zane, kamar rigunan wasanni na rini, tutocin waje, facin ɗinki da sauransu da yawa. Akwai nau'ikan hanyoyin gane gani guda uku na MimoWork zai iya bayarwa:

▮ Ganewar Kwane-kwane

Buga takardu na dijital da sublimation suna ƙaruwa, musamman a cikin kayayyaki kamar kayan wasanni, tutoci, da ɗigon hawaye. Ba za a iya yanke waɗannan yadi da almakashi ko ruwan wukake na gargajiya ba. A nan ne tsarin laser mai hangen nesa ke haskakawa. Ta amfani da kyamarar da ke da ƙuduri mai girma, injin yana ɗaukar tsarin kuma yana yankewa ta atomatik tare da zane - babu buƙatar fayil ɗin yankewa ko yankewa da hannu. Wannan ba wai kawai yana inganta daidaito ba har ma yana hanzarta samarwa.

Jagorar Aiki:

1. Ciyar da samfuran da aka ƙera >

2. Ɗauki hoton don tsarin >

3. Fara yanke laser mai siffar kwane-kwane >

4. Tattara gamawa >

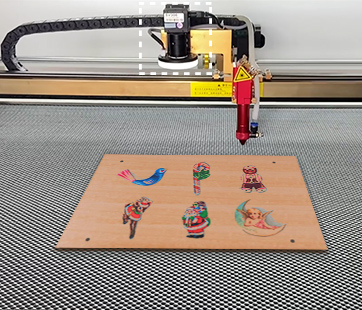

▮ Alamar Rijista

Kyamarar CCDzai iya gane da kuma gano tsarin da aka buga a kan allon katako don taimakawa laser wajen yankewa daidai. Ana iya sarrafa alamun katako, alluna, zane-zane da hoton katako da aka yi da katako da aka buga cikin sauƙi.

Mataki na 1.

>> Rubuta tsarinka kai tsaye a kan allon katako

Mataki na 2.

>> Kyamarar CCD tana taimakawa laser don yanke ƙirar ku

Mataki na 3.

>> Tattara kayan da kuka gama

▮ Daidaita Samfura

Ga wasu faci, lakabi, foils da aka buga masu girma da tsari iri ɗaya, Tsarin Matching Vision System daga MimoWork zai taimaka sosai. Tsarin laser zai iya yanke ƙaramin tsarin daidai ta hanyar gane da sanya samfurin da aka saita wanda shine fayil ɗin yanke ƙira don dacewa da ɓangaren fasalin faci daban-daban. Duk wani tsari, tambari, rubutu ko wani ɓangaren gani da ake iya gani zai iya zama ɓangaren fasalin.

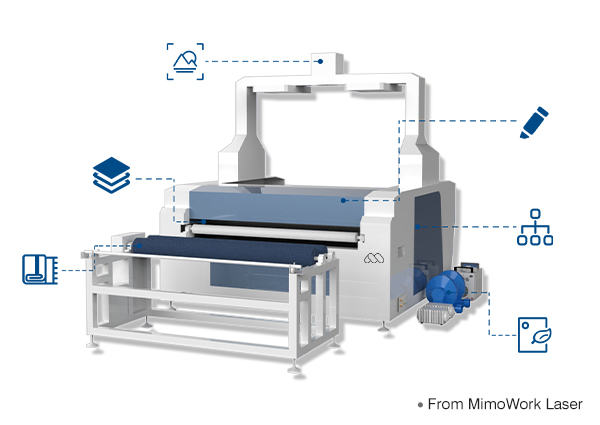

Zaɓuɓɓukan Laser

MimoWork yana ba da ƙarin zaɓuɓɓuka da yawa ga duk kayan yanke laser na asali bisa ga kowane aikace-aikacen. A cikin tsarin samarwa na yau da kullun, waɗannan ƙira na musamman akan injin laser suna da nufin ƙara ingancin samfura da sassauci bisa ga buƙatun kasuwa. Babban hanyar haɗi a farkon sadarwa da mu shine sanin yanayin samarwarku, waɗanne kayan aiki ake amfani da su a yanzu a samarwa, da kuma waɗanne matsaloli ake fuskanta a samarwa. Don haka bari mu gabatar da wasu abubuwa na zaɓi guda biyu waɗanda aka fi so.

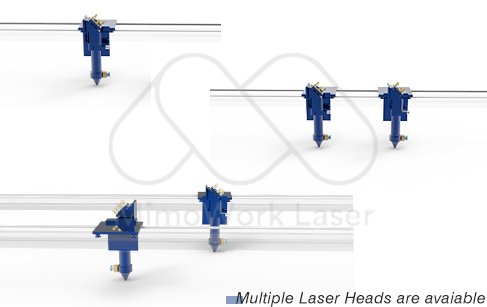

a. Kawuna da yawa na laser don ku zaɓa

Ƙara kawunan laser da bututun ƙarfe da yawa a cikin injin guda ɗaya hanya ce mai sauƙi kuma mai araha don haɓaka samarwa. Yana adana jari da sararin bene idan aka kwatanta da siyan injuna daban-daban. Amma ba koyaushe ne ya fi dacewa ba. Kuna buƙatar la'akari da girman teburin aikinku da tsarin yankewa. Shi ya sa muke yawan tambayar abokan ciniki su raba samfuran ƙira kafin yin oda.

Ƙarin tambayoyi game da injin laser ko gyaran laser

Lokacin Saƙo: Oktoba-12-2021