When you are new to laser technology and consider purchasing a laser cutting machine, there must be a lot of questions you want to ask.

MimoWork is glad to share with you more information about CO2 laser machines and hopefully, you can find a device that really suits you, whether it’s from us or another laser supplier.

In this article, we will provide a brief overview of the machine configuration in the mainstream and make a comparative analysis of each sector. In general, the article will cover the points as below:

Mechanics of the CO2 laser machine

a. Brushless DC Motor, Servo Motor, Step Motor

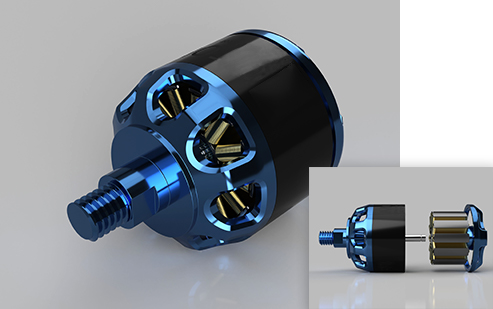

Brushless DC (direct current) motor

Brushless DC motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. The brushless dc motor is rarely seen in a CO2 laser cutting machine. This is because the speed of cutting through a material is limited by the thickness of the materials. On the contrary, you only need small power to carve graphics on your materials, A brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

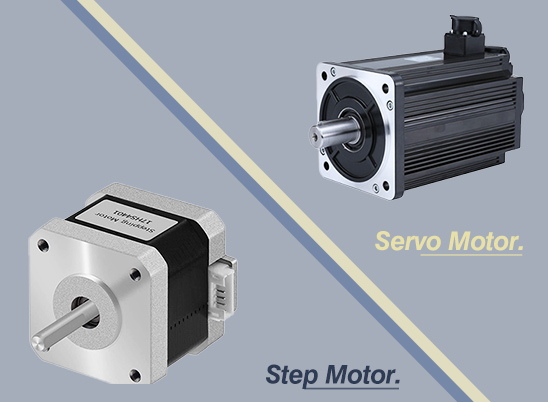

Servo motor & Step motor

When paired with a CO2 laser engraver table, servo motors offer higher torque and precision, especially for technical tasks like cutting filter cloth or insulation covers. While they cost more and require encoders and gearboxes—making the setup a bit more complex—they’re ideal for demanding applications. That said, if you’re making simple craft gifts or signage, a stepper motor on your laser engraver table usually does the job just fine.

Each motor has its pros and cons. The one that suits you is the best for you.

Certainly, MimoWork can provide the CO2 laser engraver and cutter with three types of the motor based on your requirement and budget.

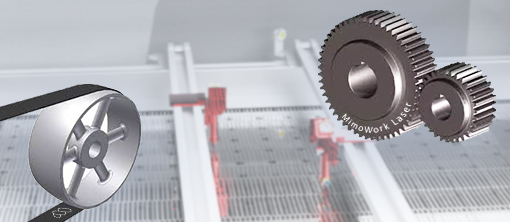

b. Belt Drive VS Gear Drive

A belt drive uses a belt to link wheels, while a gear drive connects gears directly through interlocking teeth. In laser machines, both systems help move the gantry and affect how precise the machine can be.

Let’s compare the two with the following table:

|

Belt Drive |

Gear Drive |

| Main element Pulleys and Belt | Main element Gears |

| More space required | Less space required, therefore the laser machine can be designed to be smaller |

| High friction loss, therefore lower transmission and less efficiency | Low friction loss, therefore higher transmission and more efficiency |

| Low life expectancy than gear drives, normally change every 3 years | Much greater life expectancy than belt drives, normally change every decade |

| Requires more maintenance, but the maintenance cost is relatively cheaper and convenient | Requires less maintenance, but the maintenance cost is relatively dearer and cumbersome |

| Lubrication not required | Require regular lubrication |

| Very quiet in operation | Noisy in operation |

Both gear drive and belt drive systems are commonly designed in the laser cutting machine with pros and cons. Simply summed up, the belt drive system is more advantageous in small-size, flying-optical types of machines; due to the higher transmission and durability, the gear drive is more suitable for the large-format laser cutter, normally with a hybrid optical design.

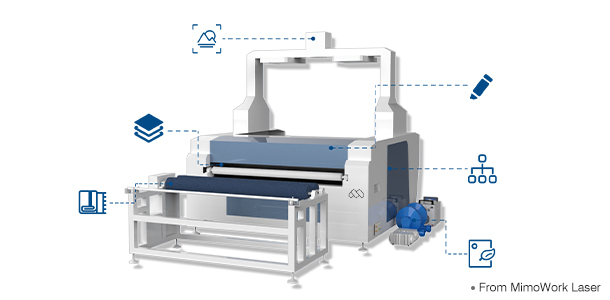

c. Stationary Working Table VS Conveyor Working Table

For the optimization of laser processing, you need more than a high-quality laser supply and an outstanding driving system to move a laser head, a suitable material support table is also needed. A working table tailored to match the material or application mean you can maximize the potential of your laser machine.

Generally, there are two categories of working platforms: Stationary and Mobile.

(For various applications, you may end up using all kinds of materials, either sheet material or coiled material)

○ A Stationary Working Table is ideal for placing sheet materials like acrylic, wood, paper (cardboard).

• knife strip table

• honey comb table

○ A Conveyor Working Table is ideal for placing roll materials like fabric, leather, foam.

• shuttle table

• conveyor table

Benefits of a suitable working table design

✔ Excellent extraction of the cutting emissions

✔ Stabilize the material, no displacement occurs when cutting

✔ Convenient to load and unload the workpieces

✔ Optimum focus guidance thanks to flat surfaces

✔ Simple care and cleaning

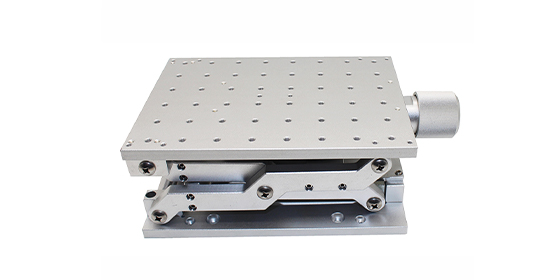

d. Automatic Lifting VS Manual Lifting Platform

When you are engraving solid materials, like acrylic (PMMA) and wood (MDF), materials vary in thickness. Appropriate focus height can optimize the engraving effect. An adjustable working platform is necessary to find the smallest focus point. For the CO2 laser engraving machine, automatic lifting and manual lifting platforms are commonly compared. If your budget is adequate, go for the automatic lifting platforms. Not only improving the cutting and engraving precision, it can also save you tons of time and effort.

e. Upper, Side & Bottom Ventilation System

The bottom ventilation system is the most common choice of a CO2 laser machine, but MimoWork also has other types of design to advance the whole laser processing experience. For a large-size laser cutting machine, MimoWork will use a combined upper and bottom exhausting system to boost the extraction effect while maintaining high-quality laser cutting results. For the majority of our galvo marking machine, we will install the side ventilation system to exhaust the fumes. All the details of the machine are to be better targeted to solve the problems of each industry.

An extraction system is generated under the material being machined. Not only extract the fume generated by thermal-treatment but also stabilize the materials, especially light-weight fabric. The larger the part of the processing surface that is covered by the material being processed, the higher is the suction effect and the resulting suction vacuum.

CO2 glass laser tubes VS CO2 RF laser tubes

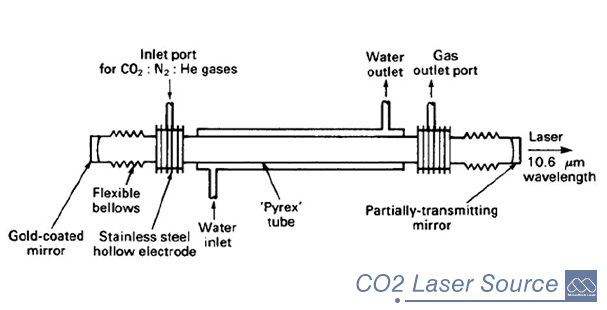

a. The excitation principle of CO2 laser

The carbon dioxide laser was one of the earliest gas lasers to be developed. With decades of development, this technology is very mature and sufficient for many applications. The CO2 laser tube excites the laser through the principle of glow discharge and converts the electrical energy into concentrated light energy. By applying a high voltage on the carbon dioxide (the active laser medium) and other gas inside the laser tube, the gas generates a glow discharge and is continuously excited in the container between the reflection mirrors where mirrors are located on the two sides of the vessel to generate the laser.

b. Difference of CO2 glass laser tube & CO2 RF laser tube

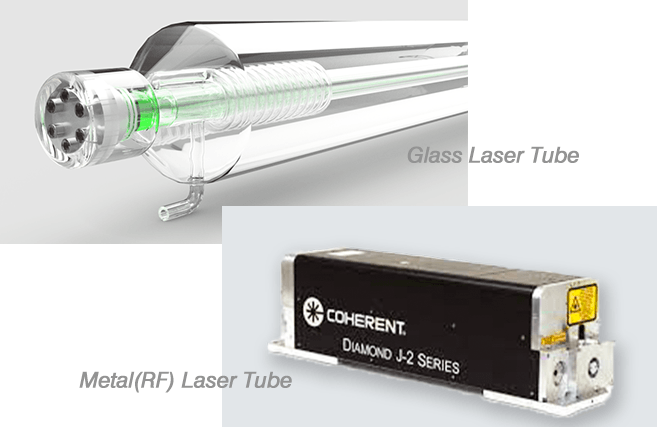

If you want to have a more comprehensive understanding of the CO2 laser machine, you have to dig into details of the laser source. As the most suitable laser type to process non-metal materials, the CO2 laser source can be divided into two main technologies: Glass Laser Tube and RF Metal Laser Tube.

(By the way, high power fast-axial-flow CO2 laser and slow-axial flow CO2 laser are not in the scope of our discussion today)

| Glass (DC) Laser Tubes | Metal (RF) Laser Tubes | |

| Lifespan | 2500-3500 hrs | 20,000 hrs |

| Brand | Chinese | Coherent |

| Cooling Method | Water Chilling | Water Chilling |

| Rechargeable | No, one time use only | Yes |

| Warranty | 6 months | 12 months |

Control System and Software

The CO2 laser cutting machine software acts as the brain of the system, using CNC programming to guide laser movement and adjust power levels. It enables flexible production by letting you switch designs quickly and handle different materials—just by tweaking laser power and cutting speed, no tool changes needed.

Many in the market will compare the software technology of China and the software technology of European and American laser companies. For simply cut and engrave pattern, the algorithms of most softwares on the market don’t differ much. With so many years of data feedback from the numerous manufactures, our software has below features:

1. Easy to use

2. Stable and safe operation in the long-term

3. Evaluate production time efficiently

4. Support DXF, AI, PLT and many other files

5. Import multiple cutting files at one time with modification possibilities

6. Auto-arrange cutting patterns with arrays of columns and rows with Mimo-Nest

Besides the basis of ordinary cutting software, the Vision Recognition System can improve the degree of automation in production, reduce labor and improve the cutting precision. In simple terms, the CCD Camera or the HD Camera installed on the CO2 laser machine acts like human eyes and instructs the laser machine where to cut. This technology is commonly used in digital printing applications and embroidery fields, such as dye-sublimation sportwear, outdoor flags, embroidery patches and many others. There are three kinds of vision recognition method MimoWork can provide:

▮ Contour Recognition

Digital and sublimation printing are on the rise, especially in products like sportswear, banners, and teardrops. These printed fabrics can’t be cut precisely with scissors or traditional blades. That’s where vision-based laser systems shine. Using a high-resolution camera, the machine captures the pattern and automatically cuts along its outline—no cutting file or manual trimming needed. This not only improves accuracy but also speeds up production.

Operation Guide:

1. Feed the patterned products >

2. Take the photo for the pattern >

3. Start the contour laser cutting >

4. Collect the finished >

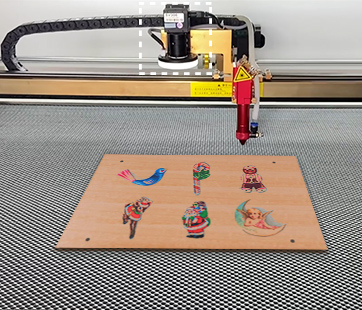

▮ Registration Mark Point

CCD Camera can recognize and locate the printed pattern on the wood board to assist the laser with accurate cutting. Wood signage, plaques, artwork and wood photo made of printed wood can be easily processed.

Step 1 .

>> Directly print your pattern on the wood board

Step 2 .

>> CCD Camera assists the laser to cut your design

Step 3 .

>> Collect your finished pieces

▮ Template Matching

For some patches, labels, printed foils with the same size and pattern, the Template Matching Vision System from MimoWork will be a great help. The laser system can accurately cut the small pattern by recognizing and positioning the set template which is the design cutting file to match the feature part of different patches. Any pattern, logo, text or other visual recognizable part can be the feature part.

Laser Options

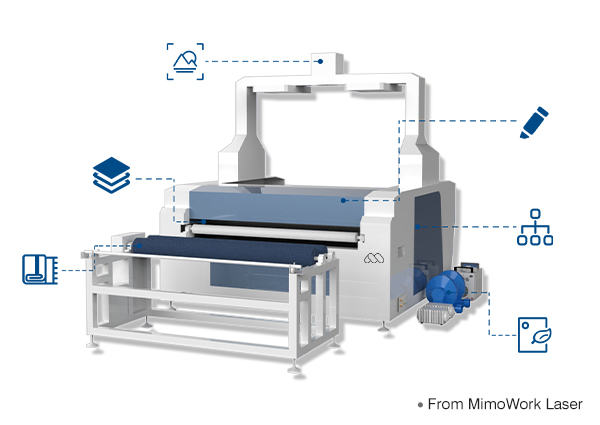

MimoWork offers numerous additional options for all fundamental laser cutters strictly according to each application. In the daily production process, these customized designs on the laser machine aim to increase the product quality and the flexibility according to the market requirments. The most important link in the early communication with us is to know your production situation, what tools are currently used in production, and what problems are encountered in production. So let’s introduce a couple of common optional components that are favored.

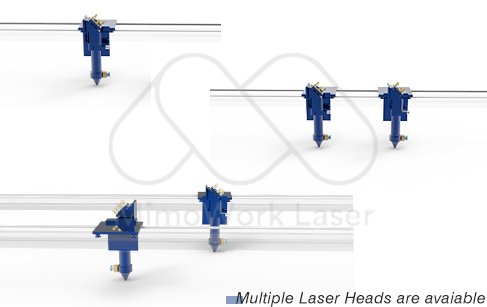

a. Multiple laser heads for you to choose

Adding multiple laser heads and tubes to a single machine is a simple and cost-effective way to boost production. It saves both investment and floor space compared to buying several separate machines. But it’s not always the best fit. You’ll need to consider the size of your working table and the cutting patterns. That’s why we usually ask customers to share sample designs before placing an order.

More questions about laser machine or laser maintenance

Post time: Oct-12-2021