Laser welding technology is a relatively new and highly sought-after welding solution in the market, with a growing demand for quality laser welder for sale to meet diverse industrial needs.

Laser welders, also referred to as laser welding machines, or laser welding tools, are used for material processing through the application of lasers.

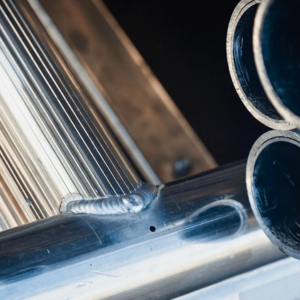

This innovative welding method is particularly ideal for welding thin-walled metals and precision components. It offers minimal deformation and excellent sealing properties for the welds.

With a small focal point and high positioning accuracy, laser welding is also easily automated, which makes it a popular choice for many industrial applications.

So, what makes hand held laser welder stand out when compared to automated laser welding machine? This article will highlight the differences and advantages of hand held laser welder, helping you make an informed decision when choosing the right machine.

1. Advantages Of Hand Held Laser Welder

A hand held laser welder is a laser welding device that requires manual operation.This portable laser welding tool is designed to weld larger components and products over long distances.

1. The welding process is characterized by a small heat-affected zone, which significantly reduces the risk of material deformation, discoloration, and marks on the reverse side of the workpiece.

2.The welding depth is significant, ensuring strong and complete fusion without indentations at the junction where the molten material meets the base.

3. The welding speed is fast, the quality is excellent, and the welds are firm, smooth, and aesthetically pleasing.

4. The weld seams are small, free from porosity, and can be precisely controlled.

No secondary processing is required, and hand held laser welder is capable of performing a wide range of weld types, including spot welding, butt welding, stack welding, seal welding, and corner welding.

Hand Held Laser Welder Welding Aluminum

Handheld Laser Welder Welding Metal

2. Differences Compared With Automated Laser Welder

Automated laser welding machines are programmed using software to automatically execute welding tasks.

By contrast, hand held laser welding system, also known as hand laser welder, is manually operated, with the operator using a magnified display for precise alignment and control.

1. The key advantage of hand held laser welder, as compared to fully automated laser system, lies in their flexibility and convenience, especially for small-scale production or non-standardized welding needs.

2. Hand held laser welder is ideal for workshops that require adaptable solutions for welding materials of varying shapes and sizes.

3. Unlike fully automated laser welder, hand laser welder do not require extensive setup or debugging, making them suitable for businesses with diverse production requirements.

Our website offers hand held laser welder, if you are interested you can click here to learn more:>>HAND HELD LASER WELDER<<

Want to Buy a Laser Welder?

3. Conclusion

In conclusion, hand laser welder offers a versatile and highly effective solution for a wide range of welding applications, especially for small-scale or customized production.

Its user-friendly operation, fast welding speeds, high-quality results, and minimal risk of material damage makes it an attractive option for many industries.

While automated laser welding machines excel in precision and automation for large-scale manufacturing, hand held laser welder stand out for their flexibility and adaptability, making it an ideal choice for handling diverse materials and irregular shapes.

Whether you are considering a laser welder for sale or exploring various options in laser welding technology, a hand held laser welder offers the perfect balance of performance, quality, and flexibility, proving to be an indispensable tool for modern manufacturing needs.

Want To Know More About Laser Welder?

Related Machine: Laser Welders

This modular handheld unit enables rapid function switching via interchangeable heads.

Achieve precision laser welding, non-contact surface cleaning (chemical-free), and portable metal cutting with a single platform.

Reduce equipment investment by 70%, minimize workspace requirements, and optimize field operations.

Engineered for maintenance, repair, and confined space applications.

Maximize operational flexibility and ROI with unified technology.

Leveraging the fiber laser’s energy concentration and adaptability, this handheld welder integrates a compact cabinet, fiber laser source, circular water-cooling system, laser control system, and ergonomic welding gun.

Its simple yet stable structure allows easy mobility. This enables users to freely maneuver the device for on-demand metal welding.

Perfect for applications like metal billboard fabrication, stainless steel joining, sheet metal cabinet assembly, and large-scale sheet metal structure welding. It streamlines field operations with unmatched convenience.

FAQS

Hand - held laser welders are versatile for metals like stainless steel, aluminum, and various alloys. They handle thin - walled metals, precision components, and even irregular - shaped materials. Ideal for metal billboards, stainless steel products, sheet metal cabinets, etc. Whether it's small - scale spot welding or large - scale structure welding, they adapt well, providing strong, aesthetic welds.

Hand - held laser welders save costs. They reduce equipment investment (e.g., 3 - in - 1 model cuts investment by 70%). Lower workspace needs and no complex programming cut operational costs. For diverse, small - batch production, they offer better ROI than automated welders needing heavy setup for large - scale runs.

It delivers high - quality welds. Small heat - affected zone, deep welding, firm and smooth seams with no porosity. Welds need no secondary processing. Achieves precise control, ensuring aesthetic and strong joints, meeting industrial standards for various applications from metal fabrication to repair work.

Post time: Jan-07-2025