No one doesn't like intricate and stunning paper crafts, ha? Such as wedding invitations, gift packages, 3D modeling, Chinese paper cutting, etc. Customized paper design art is totally a trend and a huge potential market. But obviously, manual paper cutting is not enough to meet the requirements. We need the laser cutter to help paper cutting to raise a level featuring good quality and fast speed. Why laser cutting paper is popular? How a paper laser cutter works? Finish the page you will find out.

from

Laser Cut Paper Lab

If you are into intricate and ingenious paper-cutting details, and want to blow your mind, and set free from troublesome tool use, choosing a co2 laser cutter for paper is definitely your best choice thanks to its quick prototype for any fantastic ideas. High-precision laser and accurate CNC control can create an excellent-quality cutting effect. You can use the laser to accomplish flexible shape and design cutting, serving creative work in art studios and some educational institutions. Besides art work, laser cutting paper can make big profits for businessmen. Even if you are a start-up, digital control and easy operation as well as highly efficient production make it the best cost-effective tool for you.

Laser Cut Paper is the Best! Why?

Speaking of paper cutting and engraving, CO2 laser is the best and easiest way. Due to the natural advantages of CO2 laser wavelength suitable for paper absorbing, CO2 laser cutting paper can create a high-quality cutting effect. The efficiency and speed of CO2 laser cutting cater to the demands of mass production, while minimal material waste contributes to cost-effectiveness and environmental friendliness. Moreover, the scalability, automation, and reproducibility of this method make it a practical choice for businesses looking to meet growing custom market demands. From intricate patterns to filigree designs, the technology's creative possibilities are vast, making it an indispensable tool for producing unique and eye-catching paper products for applications ranging from invitations and greeting cards to packaging and artistic projects.

Exquisite Cut Details

Flexible Multi-shapes Cutting

Distinct Engraving Mark

✦ Precision and Intricacy

✦ Efficiency and Speed

✦ Clean and Sealed Edges

✦ Automation and Reproducibility

✦ Customization

✦ No Need for Tool Replacement

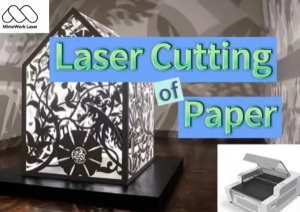

▶ Glance at a video of laser-cut paper

Finishing Diverse Laser Cut Paper Ideas

▶ What kind of paper can you laser cut?

Basically, you can cut and engrave any paper with a laser machine. Due to the high precision like 0.3mm but high energy, laser cutting paper suits different types of paper with various thicknesses. Usually, you can achieve particularly fine engraving results and haptic effects with the following paper:

• Cardstock

• Cardboard

• Grey Cardboard

• Corrugated Cardboard

• Fine Paper

• Art Paper

• Handmade Paper

• Uncoated Paper

• Kraft paper(vellum)

• Laser Paper

• Two-ply Paper

• Copy Paper

• Bond Paper

• Construction Paper

• Carton paper

▶ What can you do using laser-cut paper?

You can make versatile paper crafts and decorations. For a family's birthday, wedding celebration, or Christmas decoration, laser cutting paper helps you with quickly the task according to your ideas. Besides decoration, laser cutting paper has played a necessary part in industrial fields as the insulation layers. Taking advantage of flexible laser cutting, many artistic creations can be quickly realized. Get a laser machine, more paper applications are waiting for you to explore.

MimoWork Laser Series

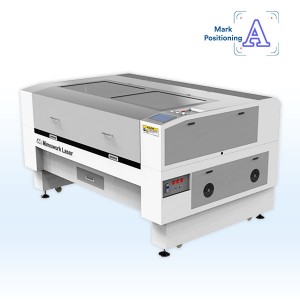

▶ Popular Laser Foam Cutter Types

Working Table Size: 1000mm * 600mm (39.3” * 23.6 ”)

Laser Power Options: 40W/60W/80W/100W

Overview of Flatbed Laser Cutter 100

Flatbed Laser Cutter is especially suitable for laser beginners to do business and is popular as a laser cutter for paper in-home use. Compact and small laser machine occupies less space and is easy to operate. Flexible laser cutting and engraving fit these customized market demands, which stands out in the field of paper crafts.

Working Table Size: 400mm * 400mm (15.7” * 15.7”)

Laser Power Options: 180W/250W/500W

Overview of Galvo Laser Engraver 40

MimoWork Galvo Laser Marker is a multi-purpose machine. Laser engraving on paper, custom laser cutting paper, and paper perforating can all be completed with the galvo laser machine. Galvo laser beam with high precision, flexibility, and lightning speed creates customized and exquisite paper crafts like invitation cards, packages, models, and brochures. For diverse patterns and styles of paper, the laser machine can kiss cut the top paper layer leaving the second layer visible to present varied colors and shapes.

Send Your Requirements to Us, We will Offer A Professional Laser Solution

▶ How to Laser Cut Paper?

Laser cutting paper depends on the automatic control system and precise laser cutting device, you just need to tell the laser your ideas, and the rest cutting process will be finished by laser. That's why the laser paper cutter is taken as a premium partner with businessmen and artists.

Paper Preparation: keep the paper flat and intact on the table.

Laser Machine: choose a suitable laser machine configuration based on productivity and efficiency.

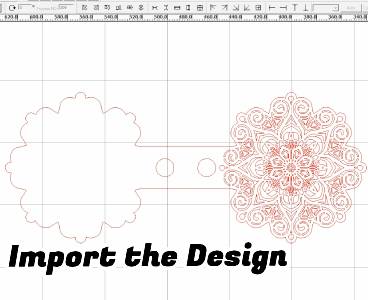

▶

Design File: import the cutting file to the software.

Laser Setting: different paper types and thicknesses determine different laser power & speed (usually high speed & low power are suitable)

▶

Start Laser Cutting: During laser cutting paper, ensure keeping the ventilation and air blowing open. Wait for a few seconds, the paper cutting will be finished.

Still confused about laser cutting paper, read on to get more information

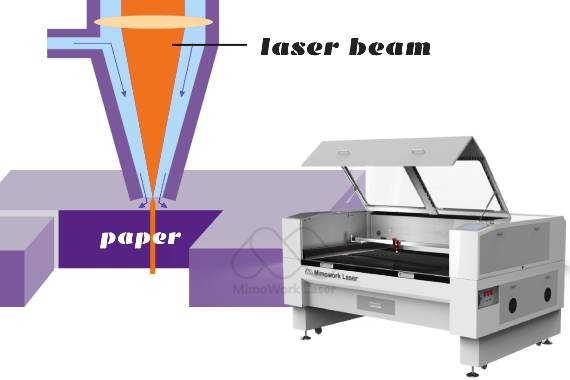

▶ How a Paper Laser Cutter Works?

▶ Tips & Attention of Laser Cutting Paper

>> Check out the detailed operation of laser engraving paper:

Start A Laser Consultant Now!

> What information you need to provide?

> Our contact information

Common questions about laser cutting paper

▶ How do you laser cut paper without burning it?

▶ Can you cut a stack of paper on a laser cutter?

▶ How to find right focus length for laser cutting paper?

▶ Can laser cutter engrave paper?

▶ Can laser kiss cut paper?

Absolutely! Thanks to the digital control system, the laser energy can be controlled by setting different powers, that can cut through or engrave in different depthes. Thus laser kiss cutting can be accomplished, such as laser cutting patches, paper, stickers, and heat transfer vinyl. The whole kiss-cutting process is automatic and highly precise.

Any confusion or questions about the laser paper cutting machine, just inquire us at any time

Post time: Nov-17-2023