China Wholesale Dual Heads Vision Laser Cutter Quotes Pricelist - Laser Wire Stripper – MimoWork Laser

China Wholesale Dual Heads Vision Laser Cutter Quotes Pricelist - Laser Wire Stripper – MimoWork Laser Detail:

Mechnical Support for your productivity

◼ Small Size

The desktop model with compact and small size.

◼ Automation Working Flow

One-key operation with automatic computer-controll system, saving time and labor.

◼ High-Speed Stripping

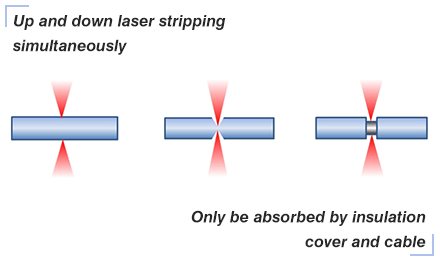

Stripping wire simultaneously by up and down dual laser heads brings high efficiency and convenience for stripping.

Technical Data

| Working Area (W * L) | 200mm * 50mm |

| Laser Power | US Synrad 30W RF Metal Laser Tube |

| Cutting Speed | 0-6000mm/s |

| Positioning Precision | within 0.02mm |

| Repeat Precision | within 0.02mm |

| Dimension | 600 * 900 * 700mm |

| Cooling Method | air cooling |

Why choose laser to strip wires?

Principle of laser stripping

During the laser wire stripping process, the energy of radiation emitted by the laser is absorbed strongly by the insulating material. As the laser penetrates the insulation, it vaporizes the material through to the conductor. However, the conductor strongly reflects the radiation at the CO2 laser wavelength and is therefore unaffected by the laser beam. Because the metallic conductor is essentially a mirror at the wavelength of the laser, the process is effective “self-terminating”, that is the laser vaporizes all of the insulating material down to the conductor and then stops, so no process control is required to prevent damage to the conductor.

Advantages from laser stripping

✔ Clean and thorough stripping for insulation

✔ No damage to the core conductor

Comparatively, conventional wire-stripping methods make physical contact with the conductor, which can damage the wire and slow down processing speed.

✔ High repetition – steady quality

Video Glance of laser stripping

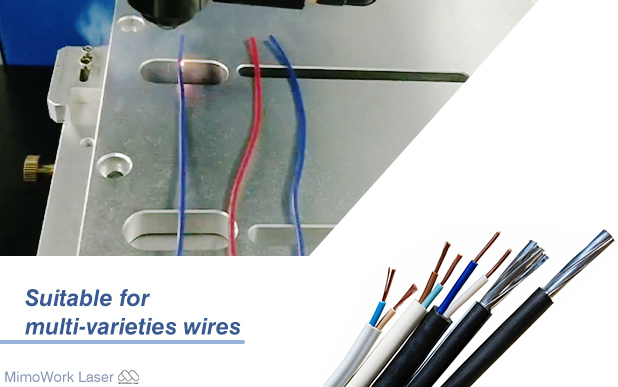

Suitable materials

Fluoropolymers (PTFE, ETFE, PFA), PTFE /Teflon®, Silicone, PVC, Kapton®, Mylar®, Kynar®, Fiberglass, ML, Nylon, Polyurethane, Formvar®, Polyester, Polyesterimide, Epoxy, Enameled coatings, DVDF, ETFE /Tefzel®, Milene, Polyethylene, Polyimide, PVDF and other hard, soft or high-temperature material…

Fields of Application

Common applications

(medical electronics, aerospace, consumer electronics and automotive)

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth, will proceed to provide aged and new buyers from home and abroad whole-heatedly for China Wholesale Dual Heads Vision Laser Cutter Quotes Pricelist - Laser Wire Stripper – MimoWork Laser , The product will supply to all over the world, such as: European , Cancun , Algeria , Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!