China Wholesale Garment Laser Cutting Machine Factories Quotes - CO2 Galvo Laser Machine for Leather Engraving & Perforating – MimoWork Laser

China Wholesale Garment Laser Cutting Machine Factories Quotes - CO2 Galvo Laser Machine for Leather Engraving & Perforating – MimoWork Laser Detail:

▶ Leather laser engraving machine for customization & batch production

Technical Data

| Working Area (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Beam Delivery | 3D Galvanometer |

| Laser Power | 180W/250W/500W |

| Laser Source | CO2 RF Metal Laser Tube |

| Mechanical System | Servo Driven, Belt Driven |

| Working Table | Honey Comb Working Table |

| Max Cutting Speed | 1~1000mm/s |

| Max Marking Speed | 1~10,000mm/s |

Structure Features

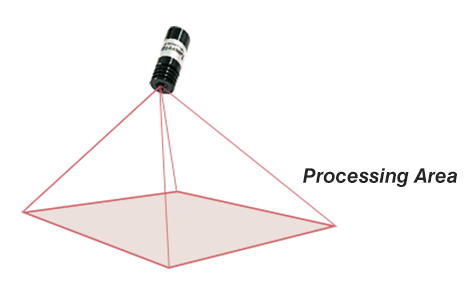

Red-light indication System

identify the processing area

By the red light indication system, you can know the practical engraving position and path to accurately fit the placement position.

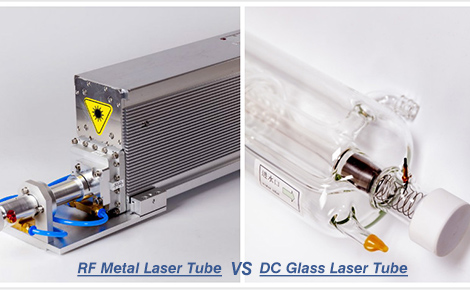

RF Metal Laser Tube

Galvo Laser Marker adopts RF (Radio Frequency) metal laser tube to meet higher engraving and marking precision. With a smaller laser spot size, intricate pattern engraving with more details, and fine holes perforating can be easily realized for leather products while speedy efficiency. High quality and long service life are the remarkable features of the metal laser tube. Besides that, MimoWork provides DC (direct current) glass laser tube to choose which is roughly 10% of the price of an RF laser tube. Pick up your suitable configuration as production demands.

>> More differences of two laser tubes

Higher Efficiency – faster speed

Directly consult us for expert laser advice as your specific requirements!

Why choose galvo laser to engrave leather

▶ High Speed

Flying marking from dynamic mirror deflection wins out in processing speed compared with flatbed lase machine. There is no mechanical movement during processing (with the exception of the mirrors), the laser beam can be guided over the workpiece at an extremely high speed.

▶ Intricate Marking

Smaller the laser spot size, higher precision of laser engraving and marking. Custom leather laser engraving on some leather gifts, wallets, crafts can be realized by the glavo laser machine.

▶ Multi-purpose in one step

Continuous laser engraving and cutting, or perforating and cutting on one step save processing time and eliminate unnecessary tool replacement. For premium processing effect, you can choose different laser powers to meet specific processing technic. Inquire us for any questions.

(leather blanks for laser engraving)

Samples from the leather laser engraving

>> Learn more laser leather works

Leather Laser Machine Recommendation

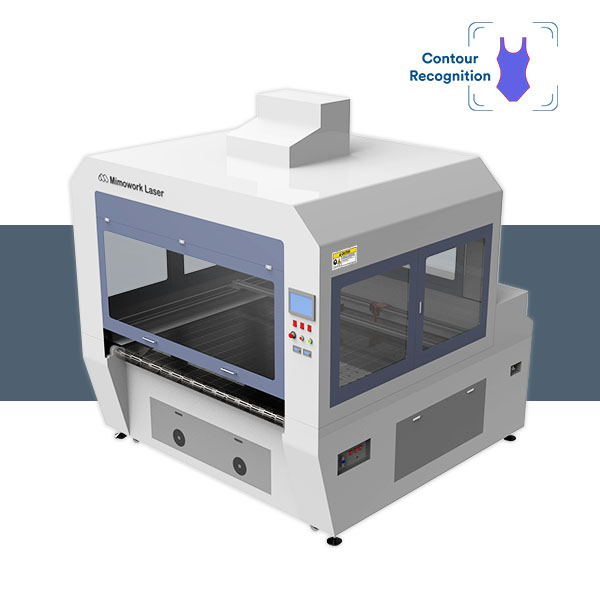

Galvo Laser Marker 40E

• Laser Power: 75W/100W

• Working Area: 400mm * 400mm

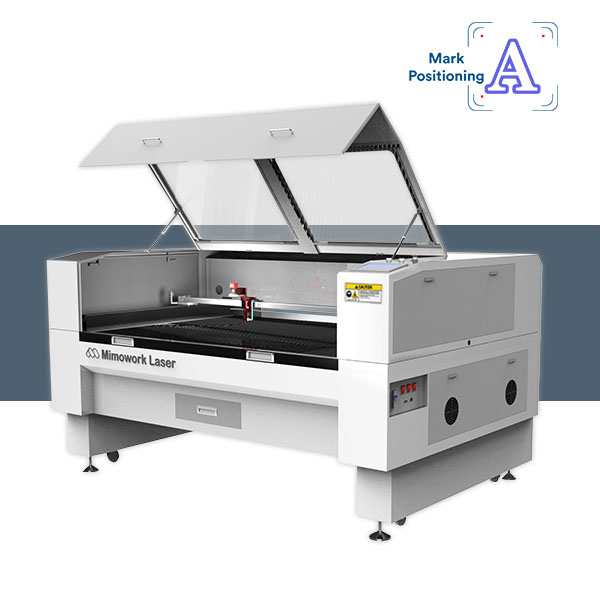

Flatbed Laser Cutting Machine 160

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 1000mm

Learn more about leather perforating machine, leather laser engraving machine price

Product detail pictures:

Related Product Guide:

Our goods are commonly recognized and reliable by consumers and may satisfy continually developing economic and social needs for China Wholesale Garment Laser Cutting Machine Factories Quotes - CO2 Galvo Laser Machine for Leather Engraving & Perforating – MimoWork Laser , The product will supply to all over the world, such as: Slovakia , Mumbai , Denmark , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!