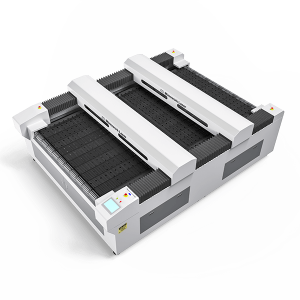

CO2 Laser Cutting Machine for Leather

▶ Standard laser cutter for leather

Technical Data

|

Working Area (W * L) |

1600mm * 1000mm (62.9” * 39.3 ”) |

|

Software |

Offline Software |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Belt Transmission & Step Motor Drive |

|

Working Table |

Conveyor Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

2350mm * 1750mm *1270mm |

|

Weight |

650kg |

* Servo Motor Upgrade Available

Giant Leap in Productivity

◆ High Efficiency

By selecting all the patterns you want to cut and setting the numbers of each leather piece, the software will nest these pieces with the most usage rate to save cutting time and materials.

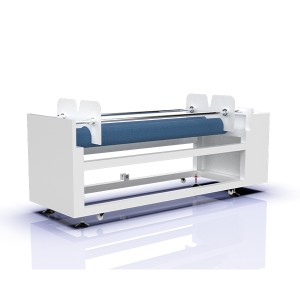

The Auto Feeder combined with the Conveyor Table is the ideal solution for roll materials to realize continuous feeding and cutting. No material distortion with stress-free material feeding.

◆ High Output

Two / Four / Multiple Laser Heads

Multiple Simultaneous Processing

To expand output and speed up production, MimoWork provides multiple laser heads to be optional to cut the same pattern simultaneously. This doesn't take extra space or labor.

◆ Flexibility

Flexible laser cutter can easily cut versatile design patterns and shapes with perfect curve cutting. Besides, fine perforating and cutting can be achieved in a single production.

◆ Safe & Solid Structure

Enclosed Design

Clean & Safe Laser Processing

Enclosed design provides a safe and clean work environment without fume and odor leaks. You can operate the laser machine and monitor the cutting condition through the acrylic window.

▶ Standard laser cutter for leather

Upgrade Options for Leather Laser Cutting

Servo Motor

What are your specific requirements?

Let's know and offer customized laser solutions for you!

Laser Cutting & Engraving Leather: Quality and Personalization

Laser Engraving Leather: Empowering Craftsmanship

(Laser Cut Leather Earrings, Laser Cut Leather Jacket, Laser Cut Leather Bag… )

Leather Samples for Laser Cutting

Common applications

• Leather Shoes

• Car Seat Cover

• Clothing

• Patch

• Accessories

• Earrings

• Belts

• Purses

• Bracelets

• Crafts

Find more videos about our laser cutters at our Video Gallery

Video glance for laser cutting shoes design

- laser cutting

✔ clean edge

✔ smooth incision

✔ pattern cutting

- laser perforating

✔ Even holes

✔ Fine perforating

Any Questions for Leather Laser Cutting?

Laser Machine Recommendation

laser cut leather machine

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 1000mm

• Extension Area: 1600mm * 500mm

leather laser engraving machine

• Laser Power: 180W/250W/500W

• Working Area: 400mm * 400mm