China Wholesale Lase Cut Tapes Manufacturers Suppliers - Textile Laser Cutting Machine – MimoWork Laser

China Wholesale Lase Cut Tapes Manufacturers Suppliers - Textile Laser Cutting Machine – MimoWork Laser Detail:

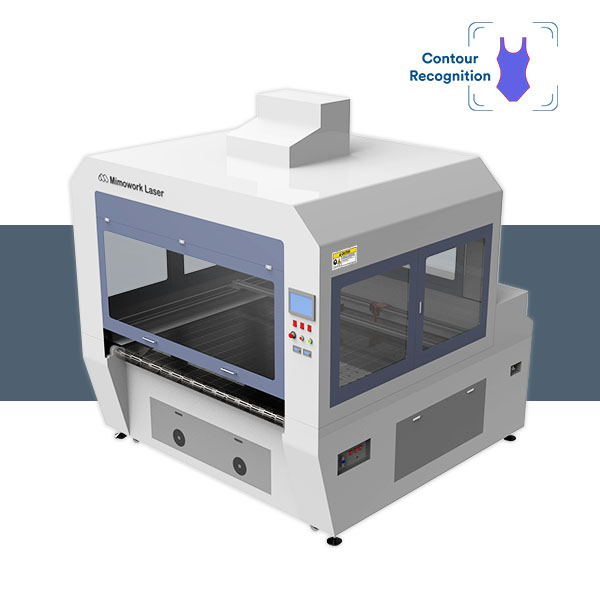

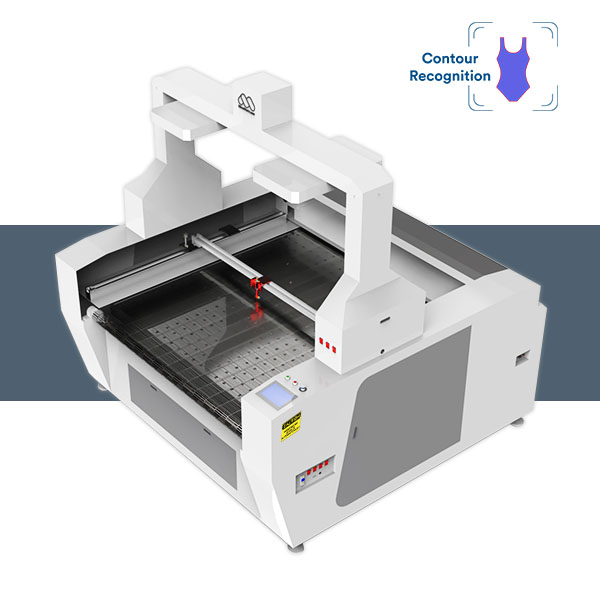

▶ Textile Laser Cutter Machine

Technical Data

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Multiple Laser Heads option available

Mechanical Structure

Safe & Stable Structure

- Signal Light

You can monitor the laser cutter status directly, helping to track productivity and avert danger.

- Emergency Button

The emergency button is intended to provide you with a high-quality safeguarding component for your laser machine. It features a simplistic, yet straightforward design that can be easily operated, greatly adding safety measures.

- Safe Circuit

Superior electronic component. It is anti-rust and corrosion-resistant as its powder-coated surface promises longer-term usage. Make sure the operation stability.

- Extension Table

The extension table is convenient for collecting fabric being cut, especially for some small fabric pieces like plush toys. After cutting, these fabrics can be conveyed to the collection area, eliminating manual collecting.

Customized Production

- Mimo-cut Software

Customize your design, Mimo-Cut software will instruct the right laser cutting on fabric. MimoWork cutting software is developed to be closer to our client’s needs, more user-friendly, and more compatible with our machines.

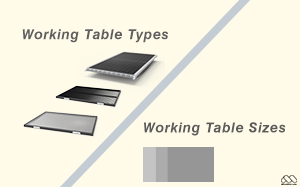

- Optional Working Table

— Optional working table types: conveyor table, fixed table (knife strip table, honey comb table)

— Optional working table sizes: 1600mm * 1000mm, 1800mm * 1000mm, 1600mm * 3000mm

• Meet varied demands for coiled fabric, pieced fabric and different formats.

High-automation

- Vacuum Suction System

MimoWork laser machine comes with two exhaust fans, one is the upper exhaust and the other is the lower exhaust. The exhaust fan can not only keep the feeding fabrics stuck still on the conveyor working table but also get you away from the possible smoke and dust, making sure that the indoor environment is always clean and nice.

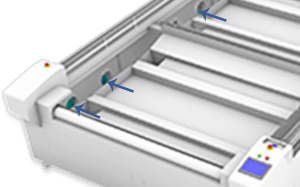

- Conveyor System

Works together with the feeding system without human intervention. The whole cutting process is continuous. Easy to get 500 sets of digitally printed garments with 6 pieces in an 8-hour shift.

Upgrade Options you can choose

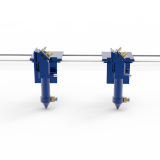

Two Laser Heads – Option

Most simply and economically to speed up your production efficiency is to mount multiple laser heads on the same gantry and cut the same pattern simultaneously. This doesn’t take extra space or labor. If you need to cut a lot of identical patterns, this would be a perfect choice for you.

Nesting Software – Option

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

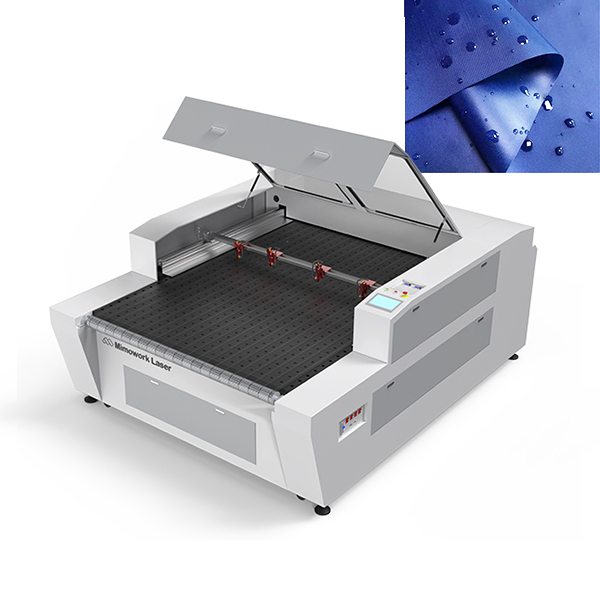

Auto Feeding System

The Auto Feeder combined with the Conveyor Table is the ideal solution for series and mass production. It transports the flexible material (fabric most of the time) from the roll to the cutting process on the laser system. With stress-free material feeding, there is no material distortion while contactless cutting with laser ensures outstanding results.

Fume Extractor – Option

Melting the surface of the material to achieve the perfect cutting result, CO2 laser processing may generate lingering gases, pungent odor, and airborne residues when you are cutting synthetic chemical materials and the CNC router can’t deliver the same precision that laser does. MimoWork Laser Filtration System can help one puzzle out the bothersome dust and fumes while minimizing disruption to production.

(laser cutting for fashion and textiles)

Fabric Samples

Pictures Browse

<a href="https://www.mimowork.com/video-gallery/" title="Source from: Video Gallery” target=”_blank”>

Source from: Video Gallery

<a href="https://www.mimowork.com/laser-cut-cotton-fabric/" title=">> More about laser cut cotton” target=”_blank”>

>> More about laser cut cotton

Video Display

How to cut cotton fabric with laser cutter

Brief steps are below:

1. Upload the garment graphic file

2. Auto-feed the cotton fabric

3. Start laser cutting

4. Collect

Related Fabric Laser Cutters

Laser Fabric Cutter

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1600mm * 1000mm

Laser Cutter for Cloth

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1600mm * 1000mm

• Collecting Area (W *L): 1600mm * 500mm

Industrial Laser Cutter for Fabric

• Laser Power: 150W/300W/500W

• Working Area (W *L): 1600mm * 3000mm

Pick your laser cutter for textile

Contact us to learn more!

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine consistently for China Wholesale Lase Cut Tapes Manufacturers Suppliers - Textile Laser Cutting Machine – MimoWork Laser , The product will supply to all over the world, such as: Mauritania , Austria , Wellington , Our items are widely recognized and trusted by users and can meet continuously developing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success!

Speaking of this cooperation with the Chinese manufacturer, I just want to saywell dodne, we are very satisfied.