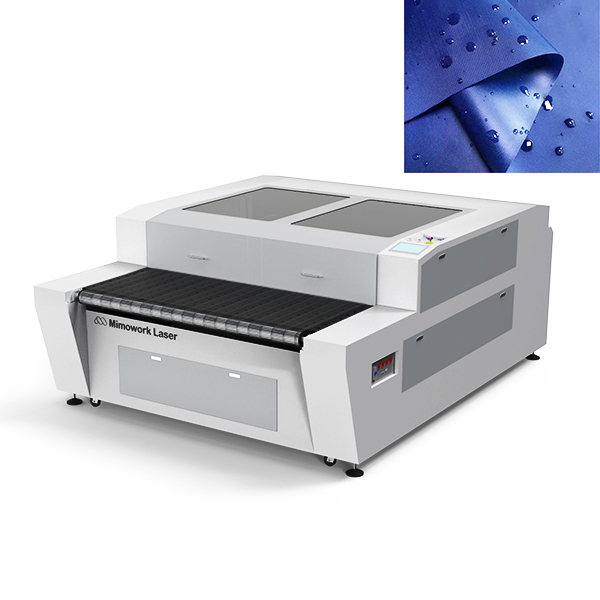

Laser Cutter for Cloth

▶ Automatic laser cloth cutting machine

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Collecting Area (W * L) | 1600mm * 500mm (62.9'' * 19.7'') |

| Software | Offline Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive / Servo Motor Drive |

| Working Table | Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Multiple Laser Heads option available

Mechanical Structure

Safe & Stable Structure

- Safe Circuit

Safe Circuit is for the safety of people in the machine environment. Electronic safety circuits implement interlock safety systems. Electronics give far greater flexibility in the arrangement of guards and the complexity of safety procedures than mechanical solutions.

- Extension Table

The extension table is convenient for collecting fabric being cut, especially for some small fabric pieces like plush toys. After cutting, these fabrics can be conveyed to the collection area, eliminating manual collecting.

- Signal Light

The signal light is designed to signal to people using the machine whether the laser cutter is in use. When the signal light turns green, it informs people that the laser cutting machine is on, all cutting work is done, and the machine is ready for people to use. If the light signal is red, it means everyone should stop and not turn on the laser cutter.

- Emergency Button

An emergency stop, also known as a kill switch (E-stop), is a safety mechanism used to shut down a machine in an emergency when it cannot be shut down in the usual way. The emergency stop ensures the safety of operators during the production process.

High-automation

Vacuum tables are commonly used in CNC machining as an effective way to hold material onto the work surface while the rotary attachment cuts. It uses the air from the exhaust fan to hold thin sheet stock flat.

The Conveyer System is the ideal solution for series and mass production. The combination of the Conveyer table and the auto feeder provides the easiest production process for cut coiled materials. It transports the material from the roll to the machining process on the laser system.

▶ Extend more possibilities on laser cutting fashion

Upgrade Options you can choose

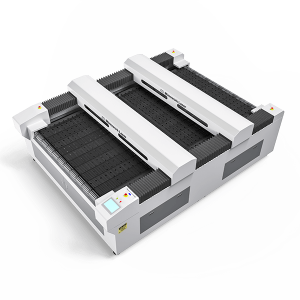

Two Laser Heads - Option

(laser cut legging, laser cut dress, laser cut clothing…)

Fabric Samples

Pictures Browse

Find more videos about our laser cutters at our Video Gallery

Video Display

Denim Fabric Laser Cutting

✦ Efficiency: Auto feeding & cutting & collecting

✦ Quality: Clean edge without fabric distortion

✦ Flexibility: Various shapes and patterns can be laser cut

How to Avoid Burning Edges When Laser Cutting Cloth?

Laser-cutting cloth can potentially result in burned or charred edges if the laser settings are not properly adjusted. However, with the right settings and techniques, you can minimize or eliminate burning, leaving clean and precise edges.

Here are some Factors to Consider to Avoid Burning when Laser Cutting Cloth:

1. Laser Power:

Lower the laser power to the minimum level required to cut through the fabric. Excessive power can generate more heat, leading to burning. Some fabrics are more prone to burning than others due to their composition. Natural fibers like cotton and silk may require different settings than synthetic fabrics like polyester or nylon.

2. Cutting Speed:

Increase the cutting speed to reduce the dwell time of the laser on the fabric. Faster cutting can help prevent excessive heating and burning. Perform test cuts on a small sample of the fabric to determine the optimal laser settings for your specific material. Adjust the settings as needed to achieve clean cuts without burning.

3. Focus:

Ensure that the laser beam is properly focused on the fabric. An unfocused beam can generate more heat and cause burning. Normally use a focus lens with a 50.8’’ focal distance when laser cutting cloth

4. Air Assist:

Use an air assist system to blow a stream of air across the cutting area. This helps disperse smoke and heat, preventing them from accumulating and causing burning.

5. Cutting Table:

Consider using a cutting table with a vacuum system to remove smoke and fumes, preventing them from settling on the fabric and causing burning. The vacuum system will also keep the fabric flat and taut during cutting. This prevents the fabric from curling or shifting, which can lead to uneven cutting and burning.

In Summary

While laser cutting cloth can potentially result in burned edges, careful control of laser settings, proper machine maintenance, and the use of various techniques can help minimize or eliminate burning, allowing you to achieve clean and precise cuts on fabric.

Related Fabric Laser Cutters

• Laser Power: 100W/150W/300W

• Working Area (W *L): 1800mm * 1000mm

• Laser Power: 150W/300W/450W

• Working Area (W *L): 1600mm * 3000mm