China Wholesale Laser Cut Dancewear Factories Quotes - CO2 Laser Engraving Machine for Acrylic (Plexiglass/PMMA) – MimoWork Laser

China Wholesale Laser Cut Dancewear Factories Quotes - CO2 Laser Engraving Machine for Acrylic (Plexiglass/PMMA) – MimoWork Laser Detail:

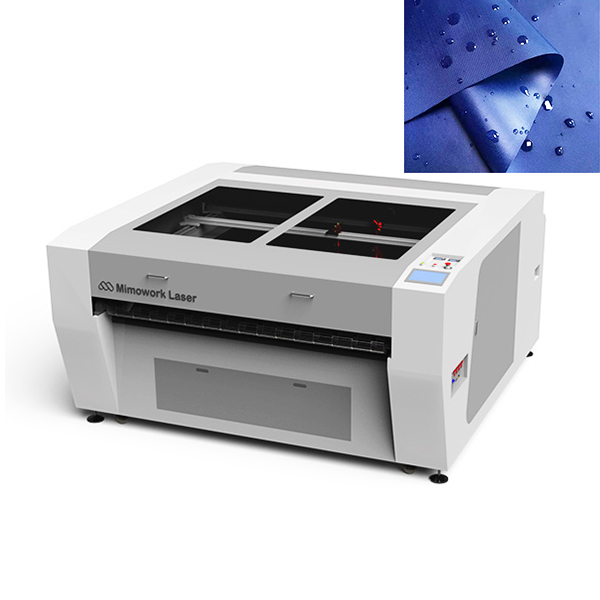

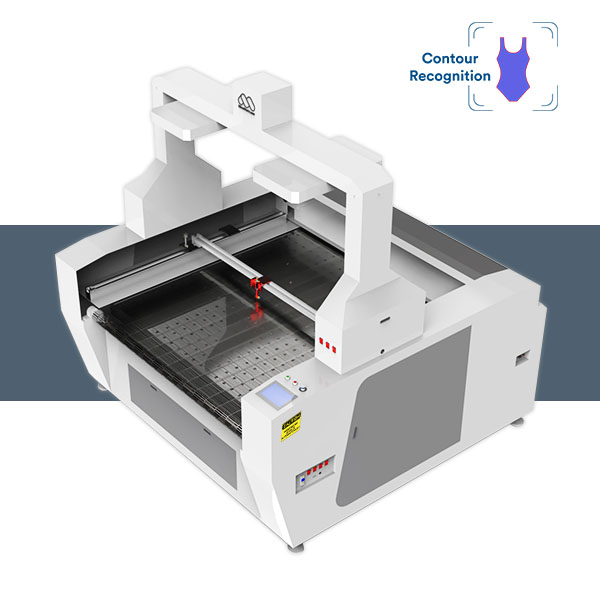

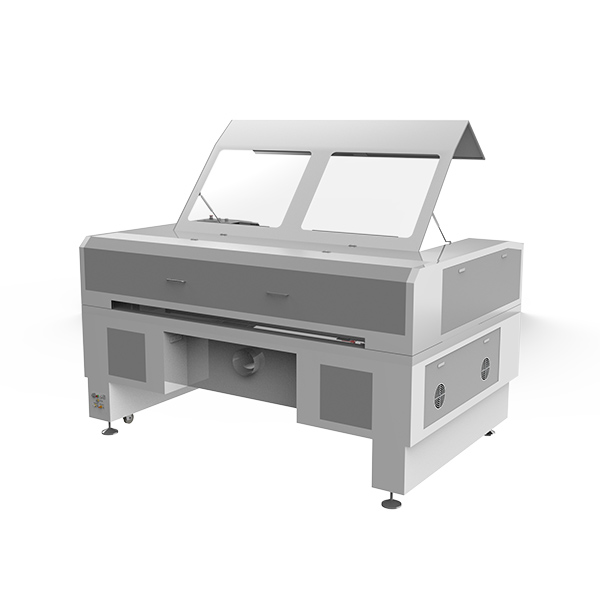

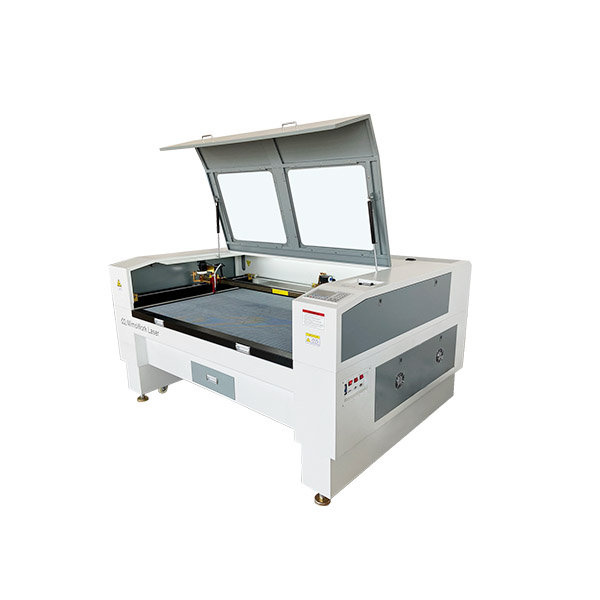

▶ laser engraving machine for acrylic (small acrylic laser cutting machine)

Technical Data

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Software |

Offline Software |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

2050mm * 1650mm * 1270mm (80.7” * 64.9” * 50.0”) |

|

Weight |

620kg |

Multifunction in One Machine

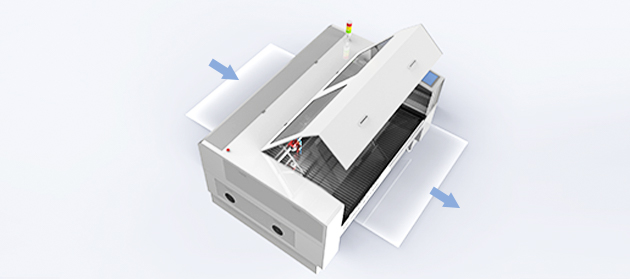

Two-way Penetration Design

Laser cutter with pass through design extends more possibilities.

Laser engraving on the large format acrylic can be realized easily thanks to the two-way penetration design, which allows acrylic panels placed through the whole width machine, even beyond the table area. Your production, whether cutting and engraving, will be flexible and efficient.

Stable and Safe Structure

◾ Signal Light

Signal light can indicate the working situation and functions exerting of laser machine, helps you to do the right judgment and operation.

◾ Emergency Button

Happen to some sudden and unexpected condition, the emergency button will be your safety guarantee by stopping the machine at once.

◾ Safe Circuit

Smooth operation makes a requirement for the function-well circuit, whose safety is the premise of safety production.

◾ CE Certification

Owning the legal right of marketing and distributing, MimoWork Laser Machine has been proud of its solid and reliable quality.

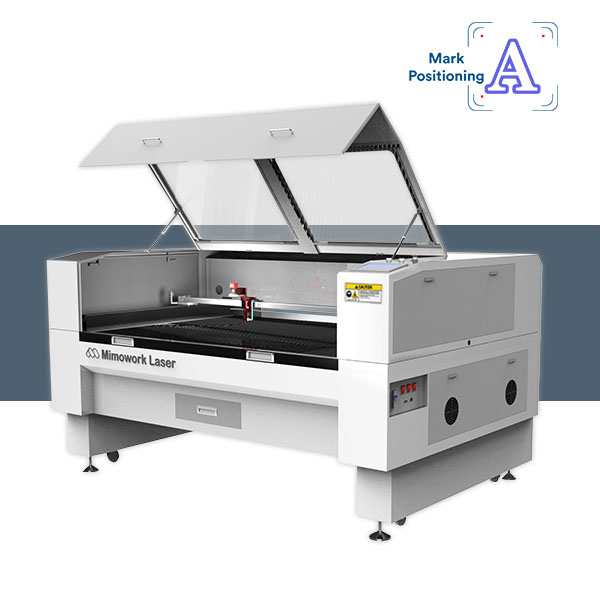

Upgrade with

CCD Camera for your printed acrylic

CCD Camera can recognize and locate the printed pattern on the acrylic board to assist the laser with accurate cutting. Advertising board, decorations, signage, branding logos, and even memorable gifts and photos made of printed acrylic can be easily processed.

Production Process

(With the acrylic laser engraver, you can laser engrave photo on acrylic, acrylic laser cut shapes)

Other upgrade options for you to choose

DC Brushless Motors

Brushless DC (direct current) motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. The brushless dc motor is rarely seen in a CO2 laser cutting machine. This is because the speed of cutting through a material is limited by the thickness of the materials. On the contrary, you only need small power to carve graphics on your materials, A brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

Rotary Attachment

If you want to engrave on the cylindrical items, the rotary attachment can meet your needs and achieve a flexible and uniform dimensional effect with a more precise carved depth. Plugin the wire into the right places, the general Y-axis movement turns into the rotary direction, which solves the unevenness of engraved traces with the changeable distance from the laser spot to the round material’s surface on the plane.

Auto Focus

It is mainly used for metal cutting. You may need to set a certain focus distance in the software when the cutting material is not flat or with different thickness. Then the laser head will automatically go up and down, keeping the same height & focus distance to match with what you set inside the software to achieve a consistently high cutting quality.

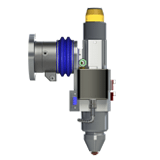

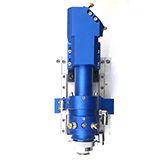

Mixed Laser Head

A mixed laser head, also known as a metal non-metallic laser cutting head, is a very important part of the metal & non-metal combined laser cutting machine. With this professional laser head, you can cut both metal and non-metal materials. There is a Z-Axis transmission part of the laser head that moves up and down to track the focus position. Its double drawer structure enables you to put two different focus lenses to cut the materials of different thicknesses without adjustment of focus distance or beam alignment. It increases cutting flexibility and makes the operation very easy. You can use different assist gas for different cutting jobs.

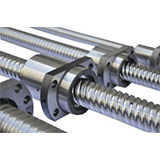

Ball & Screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional lead screws, ball screws tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. The ball screw ensures high speed and high precision laser cutting.

Samples of acrylic laser engraving

Pictures Browse

> learn about acrylic engraving” target=”_blank”>

>> learn about acrylic engraving

Videos – Laser Cut & Engrave Acrylic Display

✔ Subtle engraved pattern with smooth lines

✔ Permanent etching mark and clean surface

✔ No need for post-polishing

How to laser engrave clear acylic

→ Import your design file

→ Start the laser engraving

→ Assemble the acrylic and LED base

→ Connect to the power

Brilliant and amazing LED display is well done!

<a href="https://www.mimowork.com/laser-engraving-acrylic-display/" title=">> More details about acrylic laser cutting” target=”_blank”>

>> More details about acrylic laser cutting

Laser Cut Printed Acrylic with CCD Camera

Laser cutting printed acrylic with a CCD camera system is a cutting-edge solution that combines precision and efficiency. The CCD laser cutter uses advanced camera technology to precisely recognize printed patterns on acrylic sheets, allowing for accurate and seamless cutting. This innovative acrylic laser cutter ensures that intricate designs, logos, or artwork on the acrylic are precisely replicated without any errors. Whether you’re in the signage industry, custom fabrication, or DIY projects, the laser cutter for acrylic with CCD camera system guarantees outstanding results, making it a game-changer for anyone seeking top-notch precision and quality in their acrylic cutting projects.

Any questions about how to engrave on acrylic with laser machine

Related Laser Machine for Acrylic

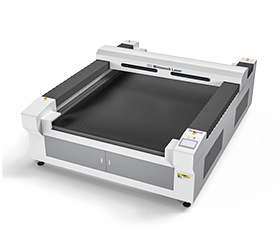

for acrylic and wood laser cutting

<a href="https://www.mimowork.com/flatbed-laser-cutting-machine/flatbed-laser-cutter-130l.html" title="Flatbed Laser Cutter 130L” target=”_blank”>

Flatbed Laser Cutter 130L

• Suitable for large format solid materials

• Cutting multi-thickness with optional power of laser tube

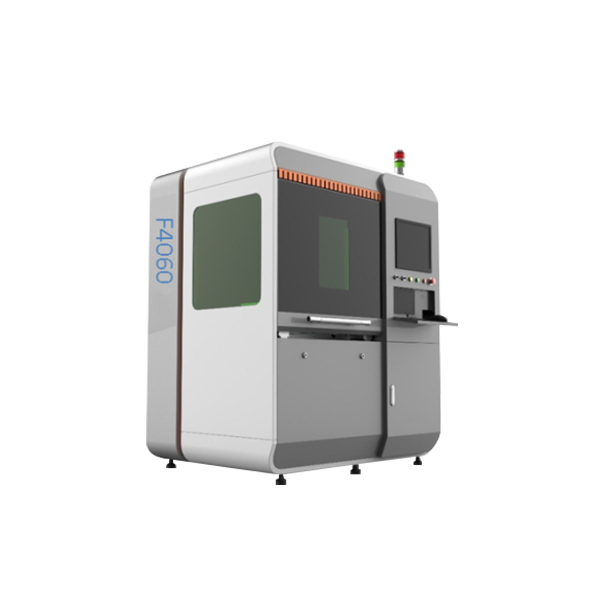

for acrylic and wood laser engraving

<a href="https://www.mimowork.com/flatbed-laser-cutting-machine/desktop-laser-engraver-70.html" title="Desktop Laser Engraver 70” target=”_blank”>

Desktop Laser Engraver 70

• Light and compact design

• Easy to operate for beginners

FAQ – Laser Cutting Acrylic & Laser Engraving Acrylic

How to determine focus point for your laser cutter

# How thick of acrylic can a laser cutter cut?

The cutting thickness of acrylic with a CO2 laser cutter depends on the power of the laser and the type of CO2 laser machine being used. Generally, a CO2 laser cutter can cut acrylic sheets ranging from a few millimeters to several centimeters in thickness.

For lower-powered CO2 laser cutters commonly used in hobbyist and small-scale applications, they can typically cut acrylic sheets up to around 6mm (1/4 inch) in thickness.

However, more powerful CO2 laser cutters, especially those used in industrial settings, can handle thicker acrylic materials. High-powered CO2 lasers can cut through acrylic sheets ranging from 12mm (1/2 inch) up to 25mm (1 inch) or even thicker.

We had a test for laser cutting thick acrylic up to 21mm with 450W laser power, the effect is beautiful. Check out the video to find more.

How to laser cut 21mm thick acrylic

# Can laser cut oversized acrylic signage?

How to laser cut an oversized acrylic sign larger than your laser bed? The 1325 laser cutting machine(4*8 feet laser cutting machine) will be your first choice. With the pass-through laser cutter, you can laser cut an oversized acrylic sign larger than your laser bed. Laser cutting signage including wood and acrylic sheet cutting is so easy to complete. Our 300W laser cutting machine has a stable transmission structure – gear & pinion and high precision servo motor driving device, ensuring the whole laser cutting plexiglass with continuous high quality and efficiency. We have high power 150W, 300W, 450W, and 600W for your laser cutting machine acrylic sheet business. Besides laser cutting acrylic sheets, the PMMA laser cutting machine can realize elaborate laser engraving on wood and acrylic.

How to laser cut large-size acrylic signage & display

Learn more about acrylic laser engraving machine price

Add yourself to the list!

Product detail pictures:

Related Product Guide:

To create extra value for customers is our enterprise philosophy; buyer growing is our working chase for China Wholesale Laser Cut Dancewear Factories Quotes - CO2 Laser Engraving Machine for Acrylic (Plexiglass/PMMA) – MimoWork Laser , The product will supply to all over the world, such as: Liberia, Ireland, Adelaide, Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.