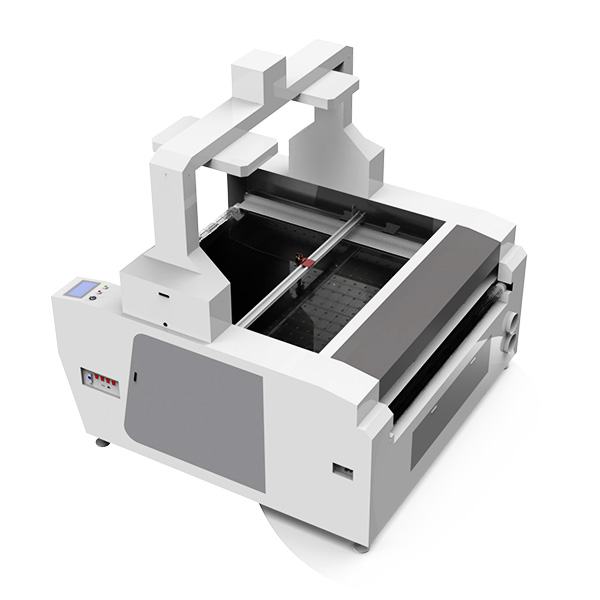

China Wholesale Laser Cut Sportswear Factories Pricelist - Contour Laser Cutter 160L – MimoWork Laser

China Wholesale Laser Cut Sportswear Factories Pricelist - Contour Laser Cutter 160L – MimoWork Laser Detail:

Unrivaled Choice for Cutting Dye Sublimation Fabric

A Giant Leap in Productivity

Technical Data

| Working Area (W *L) | 1600mm * 1200mm (62.9” * 47.2”) |

| Max Material Width | 62.9” |

| Laser Power | 130W |

| Laser Source | CO2 Glass Laser Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

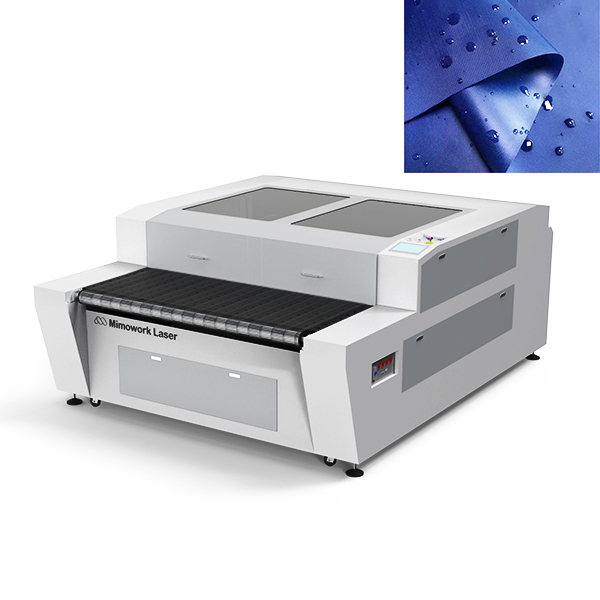

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

R&D for Flexible Material Cutting

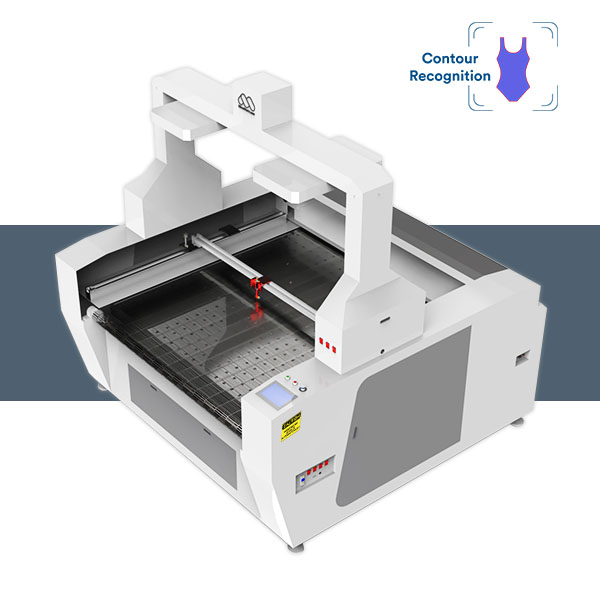

Outline Contour Detection

The Contour Recognition System detects the contour according to the color contrast between the printing outline and material background. No need to use the original patterns or files. After automatic feeding, printed fabrics will be directly detected. This is a fully automatic process without human intervention. Moreover, the camera will take photos after the fabric is fed to the cutting area. The cutting contour will be adjusted to eliminate deviation, deformation, and rotation, thus, you can eventually achieve a highly precise cutting result.

Template Matching

When you are trying to cut high distortion contours or pursue super high precise patches and logos, the Template Matching System is more suitable than the contour cut. By matching your original design templates with the photos taken by the HD camera, you can easily get the exact same contour that you want to cut. Also, you can set deviation distances according to your personalized requirements.

Mimo-PROTOTYPE

You don’t have to worry if you can not design. With the Mimo-PROTOTYE, you can create your own cutting contours anytime. For example, you can place a piece of garment on the working table of your Contour Laser Cutter 160L, the camera will take a photo of it, and you can save the file of this pattern in your PC. Then you can start to produce right away!

Independent Dual Heads

For a basic two laser heads cutting machine, the two laser heads are mounted on the same gantry, so they can not cut different patterns at the same time. However, for many fashion industries like dye sublimation apparel, for example, they may have the front, back, and sleeves of a jersey to cut. At this point, the independent dual heads can handle pieces of different patterns at the same time. This option boosts the cutting efficiency and production flexibility to the largest degree. Output can be increased from 30% to 50%.

Video Demonstration of Laser Cutting Cordura®

Find more videos about our laser cutters at our Video Gallery

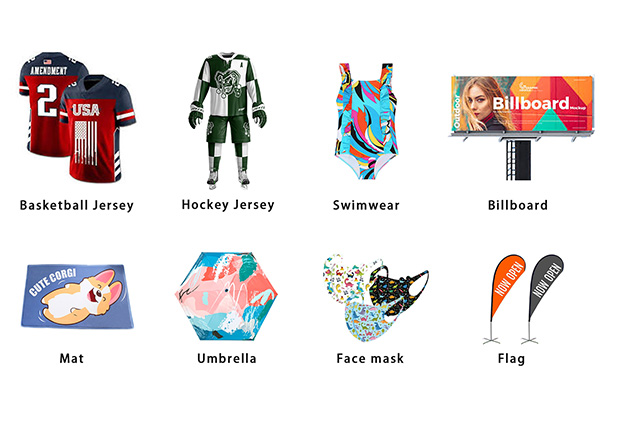

Fields of Application

Laser Cutting for Your Industry

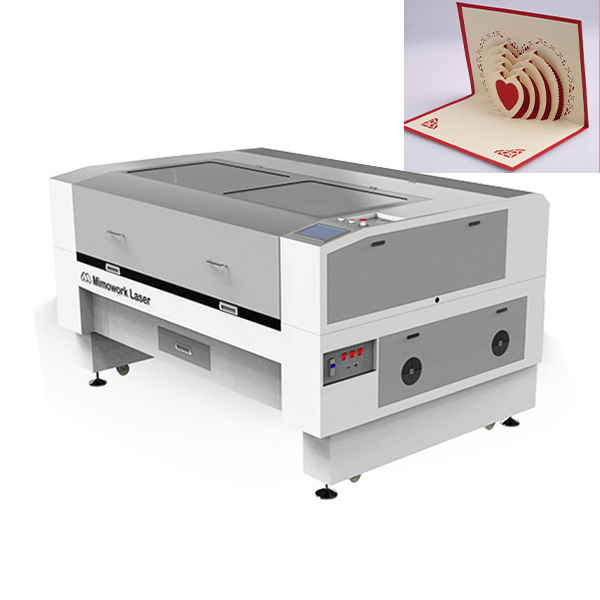

Advertising & Gifts

Unique advantages of laser cutting signs & decorations

Common materials and applications

of Flatbed Laser Cutter 160L

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our company. These principles today much more than ever form the basis of our success as an internationally active mid-size business for China Wholesale Laser Cut Sportswear Factories Pricelist - Contour Laser Cutter 160L – MimoWork Laser , The product will supply to all over the world, such as: Sevilla , Greenland , Pretoria , Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.