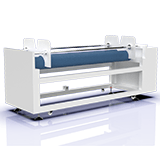

China Wholesale Laser Cut Synthetical Textiles Quotes Pricelist - Flatbed Laser Cutter 160L – MimoWork Laser

China Wholesale Laser Cut Synthetical Textiles Quotes Pricelist - Flatbed Laser Cutter 160L – MimoWork Laser Detail:

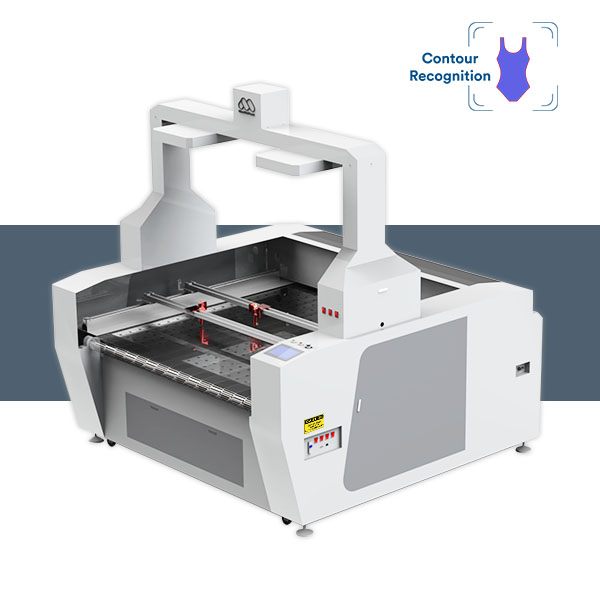

Advantages of Flatbed Laser Cutter

A Giant Leap in Productivity

Technical Data

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Max Material Width | 62.9’’ |

| Software | Offline Software |

| Laser Power | 150W/300W/500W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack & Pinion Transmission and Servo Motor Driven |

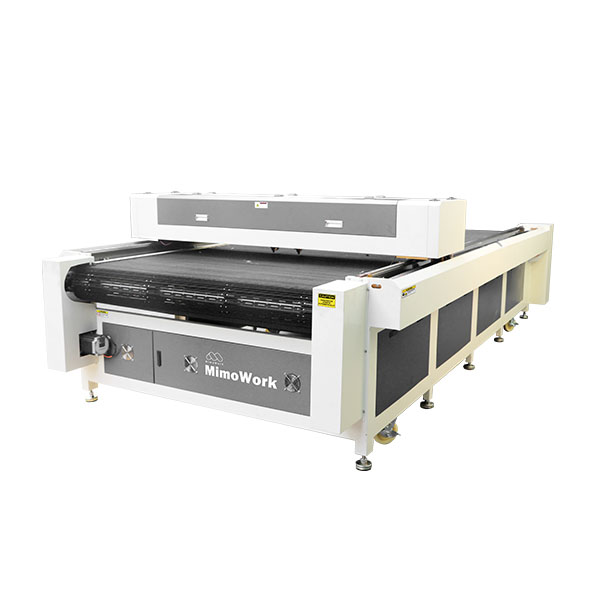

| Working Table | Conveyor Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

R&D for Flexible Material Cutting

Auto Feeder

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. The feeder will convey the roll materials to the cutting table after you put the rolls on the feeder. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process.

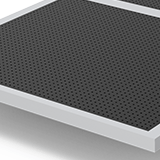

Vacuum Suction

The Vacuum Suction lies under the cutting table. Through the small and intensive holes on the surface of the cutting table, the air ‘fastens’ the material on the table. The vacuum table does not get in the way of the laser beam while cutting. On the contrary, together with the powerful exhaust fan, it enhances the effect of smoke & dust prevention during cutting.

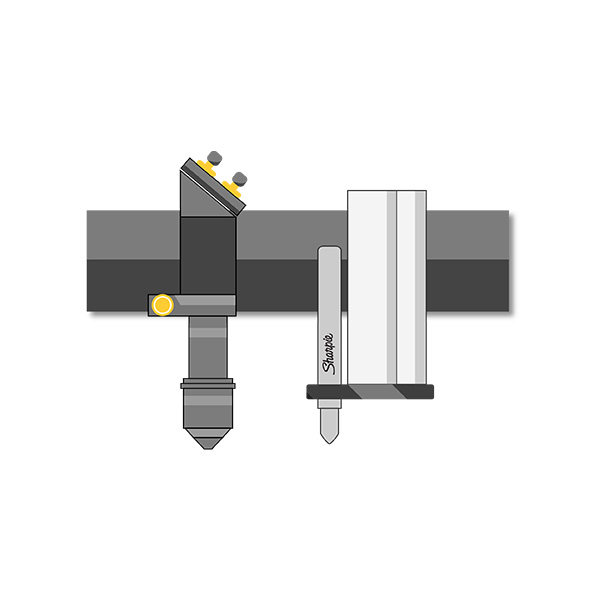

Marker Pen

For most manufacturers, especially in the clothing industry, pieces need to be sewn right after the cutting process. Thanks to the Marker Pen, you can make marks such as the serial number of the product, the size of the product, the manufacture date of the product, etc to increase overall efficiency. You can choose different colors as per your needs.

Video Demonstration of Laser Cutting Dye Sublimation Sportswear

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Clothing & Home Textiles

Clean and smooth edge with thermal treatment

Outdoor Equipment

The secret of exquisite pattern cutting

Composite Materials

Engraving, marking, and cutting can be realized in single process

Automotive & Aviation

The secret of exquisite pattern cutting

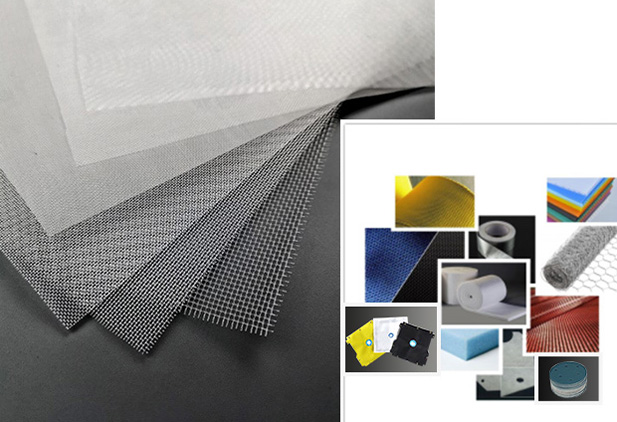

Common materials and applications

of Flatbed Laser Cutter 160L

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Product detail pictures:

Related Product Guide:

With this motto in mind, we've come to be one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Wholesale Laser Cut Synthetical Textiles Quotes Pricelist - Flatbed Laser Cutter 160L – MimoWork Laser , The product will supply to all over the world, such as: UK , Kenya , Slovakia , Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.