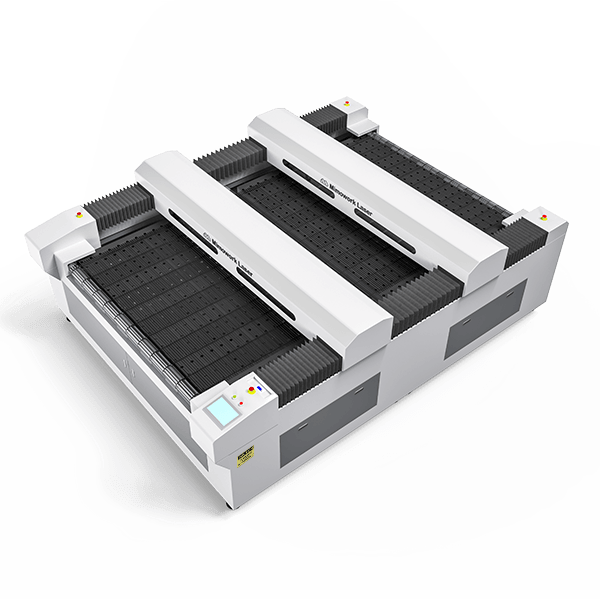

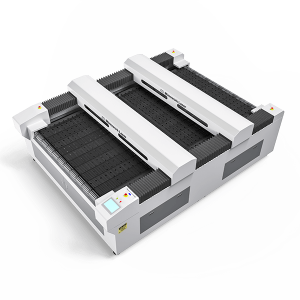

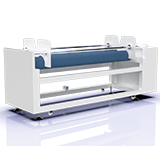

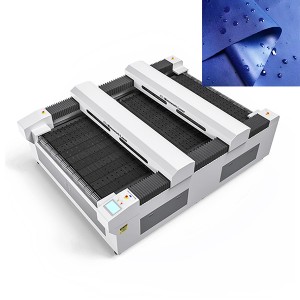

Flatbed Laser Cutter 160L

Advantages of Industrial Laser Cutter for Fabric

A Giant Leap in Productivity

◉ Higher productivity, more economical working - save time and money

◉ Ideal working table size for all applications requiring plenty of space

◉ The constant light path design guarantees the stability of the optical path, same cutting effects from near-point and far-point

◉ Conveyor System can feed the textiles automatically and achieve continuous cutting

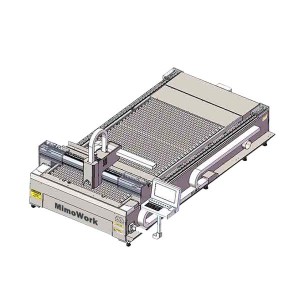

◉ Advanced mechanical structure allows laser options and customized working table

Technical Data

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Max Material Width | 1600mm (62.9’’) |

| Software | Offline Software |

| Laser Power | 150W/300W/450W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack & Pinion Transmission and Servo Motor Driven |

| Working Table | Conveyor Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

* Two independent laser gantries are available to double your efficiency.

R&D for Fabric Laser Cutting

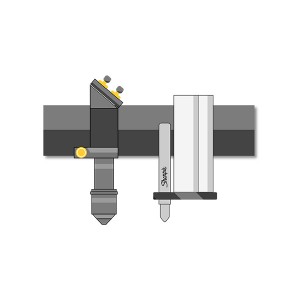

CO2 RF Laser Source - Option

Fields of Application

Laser Cutting Non-Metal Applications

Clean and smooth edge with thermal treatment

✔ Bringing about the more economical and environment-friendly manufacturing processes fortextiles applications

✔ Customized working tables help you process different formats of fabrics

✔ Quick response to market from samples to large-lot production

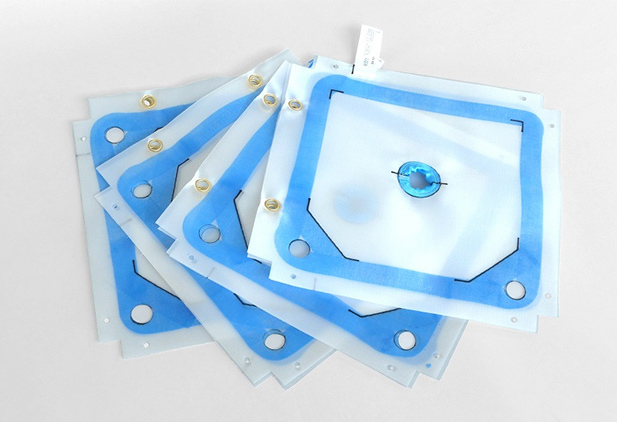

The secret of exquisite pattern cutting

The selection of appropriate filter media decides the quality and economy of an entire filtration process, including solid-liquid separation and air filtration. Laser has been considered as the best technology for cutting filter media (Filter Cloth, Filter Foam, Fleece, Filter Bag, Filter Mesh, and other filtration applications)

High Power Laser Cutting

Laser cutting can deliver high precision and constant quality results with fine laser beam. Inherent thermal processing guarantees sealed and smooth edges without fray and breakage on composite materials.

✔ Fewer material waste, no tool wear, better control of production costs

✔ Ensures a safe working environment during operation

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

Seamless laser cutting laminated fabric

The performance requirements are much higher for outdoor fabric. Sun protection, breathability, waterproof, wear resistance, all these functions usually require multiple layers of materials. Our industrial laser cutter is the most suitable tool for cutting such fabrics.

✔ High-quality value-added laser treatments

✔ Customized tables meet requirements for varieties of materials formats

of Flatbed Laser Cutter 160L

Materials: Textiles, Leather, Nylon, Kevlar, Velcro, Polyester, Coated Fabric, Dye Sublimation Fabric, Industrial Materials, Synthetic Fabric, and other Non-metal Materials

Applications: Technical Clothing, Bulletproof Vest, Automotive Interior, Car Seat, Airbags, Filters, Air Dispersion Ducts, Home Textile (Carpets, Mattress, Curtains, Sofas, Armchairs, Textile Wallpaper), Outdoor (Parachutes, Tents, Sports Equipment)