Handheld Laser Welder

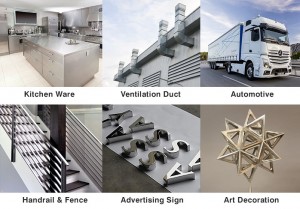

Apply Laser Welding to Your Production

How to choose the suitable laser power for your welded metal?

Single-side Weld Thickness for Different Power

| 500W | 1000W | 1500W | 2000W | |

| Aluminum | ✘ | 1.2mm | 1.5mm | 2.5mm |

| Stainless Steel | 0.5mm | 1.5mm | 2.0mm | 3.0mm |

| Carbon Steel | 0.5mm | 1.5mm | 2.0mm | 3.0mm |

| Galvanized Sheet | 0.8mm | 1.2mm | 1.5mm | 2.5mm |

Why Laser Welding ?

1. High Efficiency

▶ 2 – 10 times welding efficiency compared with traditional arc welding ◀

2. Excellent Quality

▶ Continuous laser welding can create strong & flat welding joints without porosity ◀

3. Low Running Cost

▶ Saving 80% running cost on electricity compared with arc welding ◀

4. Long Service Life

▶ Stable fiber laser source has a long lifespan of an average of 100,000 working hours, less maintenance is required ◀

High Efficiency & Fine Welding Seam

Specification - 1500W Handheld Laser Welder

|

Working mode |

Continuous or modulate |

|

Laser wavelength |

1064NM |

|

Beam quality |

M2<1.2 |

|

General Power |

≤7KW |

|

Cooling system |

Industrial Water Chiller |

|

Fiber length |

5M-10MCustomizable |

|

Welding thickness |

Depend on material |

|

Weld seam requirements |

<0.2mm |

|

Welding speed |

0~120 mm/s |

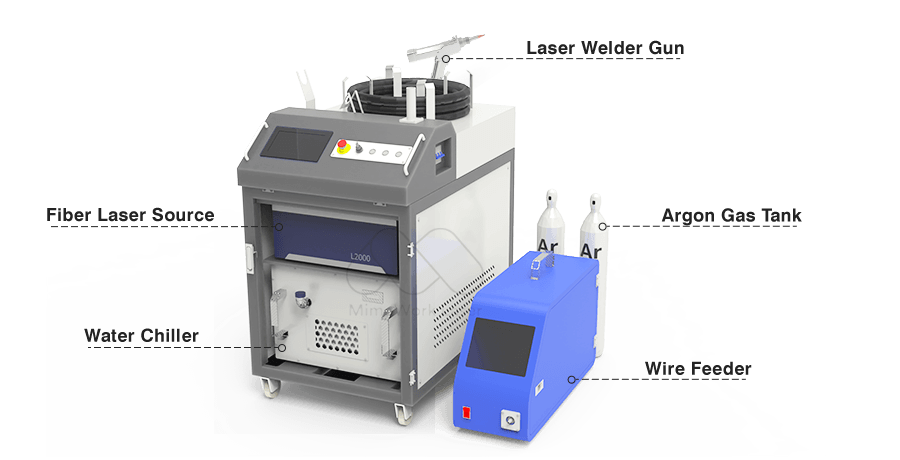

Structure Detail - Laser Welder

◼ Light and compact structure, occupying small space

◼ Pulley installed, easy to move around

◼ 5M/10M long fiber cable, weld conveniently

▷ 3 Steps Finished

Simple Operation - Laser Welder

Step 1: Turn on the boot device

Step 2: Set the laser welding parameters (mode, power, speed)

Step 3: Grab the laser welder gun and start laser welding

Comparison: laser welding VS arc welding

|

Laser Welding |

Arc Welding |

|

|

Energy Consumption |

Low |

High |

|

Heat Affected Area |

Minimum |

Large |

|

Material Deformation |

Barely or no deformation |

Deform easily |

|

Welding Spot |

Fine welding spot and adjustable |

Large Spot |

|

Welding Result |

Clean welding edge with no further processing needed |

Extra polish work needed |

|

Process Time |

Short welding time |

Time-consuming |

|

Operator Safety |

Ir-radiance light with no harm |

Intense ultraviolet light with radiation |

|

Environment Implication |

Environmentally friendly |

Ozone and nitrogen oxides (harmful) |

|

Protective Gas Needed |

Argon |

Argon |

Why choose MimoWork

✔ 20+ Years of laser experience

✔ CE & FDA Certificate

✔ 100+ laser technology and software patents

✔ Customer-oriented service concept

✔ Innovative laser development & research

Video Tutorial

Quickly Master Handheld Laser Welding !

What is Handheld Laser Welder?

How to use Handheld Laser Welder?

Laser Welding Vs TIG Welding: Which one is Better?

5 Things About Laser Welding (That you Missed)

FAQ

It works well with aluminum, stainless steel, carbon steel, and galvanized sheets. The weldable thickness varies by material and laser power (e.g., 2000W handles 3mm stainless steel). Suitable for most common metals in industrial production.

Very quick. With 3 simple steps (power on, set parameters, start welding), even new users can master it in hours. No complex training is needed, saving time on operator learning curves.

Little maintenance is required. The fiber laser source has a 100,000-hour lifespan, and the compact structure with durable parts reduces upkeep needs, lowering long-term costs.