[Laser Rust Removal]

• What is laser removal of rust?

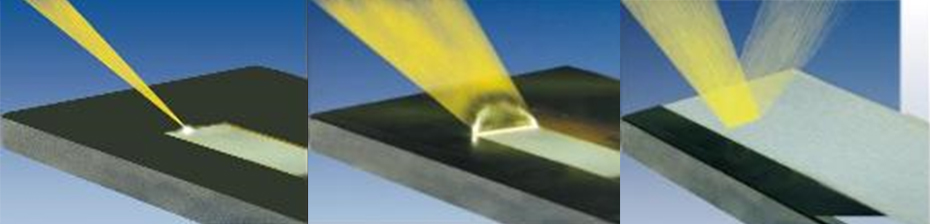

Rust is a common problem that affects metal surfaces, and it can cause significant damage if left untreated.Laser removal of rust is becoming the go-to solution for industries looking to clean metal surfaces efficiently. Unlike traditional abrasive methods, it offers a non-contact, eco-friendly, and precise cleaning process with minimal surface damage.

• How much is laser rust removal machine?

The cost of a laser rust removal machine varies depending on the size and power of the machine. Small machines with a lower power output can cost around $20,000, while larger machines with higher power output can cost up to $100,000 or more. However, the benefits of investing in a laser cleaning machine are numerous and may outweigh the initial cost.

What the benefits of investing a laser cleaning machine

▶ Precision

One of the primary benefits of using a laser cleaning machine is its precision. The laser beam is directed at the specific areas of the metal surface affected by rust, which means that only the rust is removed, leaving the rest of the surface untouched. This level of precision minimizes the risk of damaging the metal and ensures that the rust is removed completely.

▶ Speed

Another benefit of using laser for cleaning metal is the speed of the process. The laser removes rust much faster than traditional methods, which saves time and increases productivity. The laser can also be programmed to work autonomously, which allows the operator to focus on other tasks while the laser does its job.

▶ Eco-Friendly

Another benefit of using laser for cleaning metal is the speed of the process. The laser removes rust much faster than traditional methods, which saves time and increases productivity. The laser can also be programmed to work autonomously, which allows the operator to focus on other tasks while the laser does its job.

Overall, investing in a laser cleaning machine is a wise decision for businesses that frequently deal with rust removal. The benefits of precision, speed, and environmental safety make it a cost-effective and efficient option in the long run.

Laser rust removal technology has become the preferred solution for cleaning metal surfaces due to its high efficiency, environmental friendliness, and precision. Although the initial investment in laser rust removal equipment is relatively high, its fast processing speed, reduced material damage, and lower maintenance costs offer significant cost benefits over the long term. Compared to traditional methods, laser rust removal not only improves safety and cleaning quality but also brings smarter solutions to industrial cleaning.

FAQS

It is a cleaning method that uses high-powered laser beams to precisely remove rust from metal surfaces without damaging the underlying material.

Laser removal is faster, more precise, environmentally friendly, and non-contact, reducing surface damage and chemical use compared to sandblasting or chemical treatments.

Yes, it works effectively on various metals including steel, aluminum, and copper, but parameters may be adjusted based on the metal type.

Benefits include high precision, speed, reduced material wear, minimal environmental impact, and lower maintenance costs.

Although the upfront cost is higher, the long-term savings in labor, materials, and downtime often make it a cost-effective investment.

Recommended: Fiber Laser Cleaner

Choose the one that suits your requirement

Any confusions and questions for handheld laser cleaning machine?

Post time: Feb-23-2023