A Beginner's Guide to Laser Cutting Acrylic Jewelry

How to make acrylic jewelry by laser cutter

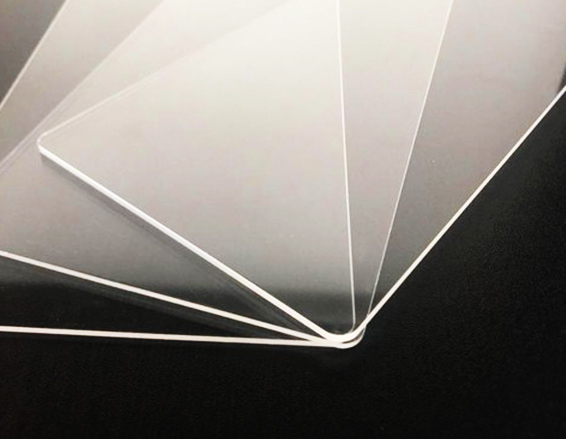

Laser cutting is a popular technique used by many jewelry designers to create intricate and unique pieces. Acrylic is a versatile material that is easy to laser cut, making it a great choice for jewelry-making. If you're interested in creating your own laser cut acrylic jewelry, this beginner's guide will walk you through the process step-by-step.

Step 1: Choose Your Design

The first step in laser cutting acrylic jewelry is to choose your design. There are many different designs available online, or you can create your own custom design using software like Adobe Illustrator or CorelDRAW. Look for a design that matches your style and preferences, and that will fit within the size of your acrylic sheet.

Step 3: Prepare Your Design

Once you have your design and acrylic selected, it's time to prepare your design for laser cutting. This process involves converting your design into a vector file that the acrylic laser cutter can read. If you're not familiar with this process, there are many tutorials available online, or you can seek the assistance of a professional graphic designer.

Step 4: Laser Cutting

Tips and Tricks for Success

Choose a design that is not too intricate for your level of experience with laser cutting.

Experiment with different acrylic colors and finishes to find the perfect look for your jewelry.

Be sure to use a high-quality acrylic laser cutter to ensure precise and accurate cutting.

Use proper ventilation when laser cutting acrylic to avoid harmful fumes.

Be patient and take your time with the laser cutting process to ensure precision and accuracy.

In Conclusion

Laser cutting acrylic jewelry is a fun and creative way to express your personal style and make unique pieces that you won't find anywhere else. While the process may seem daunting at first, with the right design, acrylic, and finishing touches, you can create stunning and sophisticated jewelry that will be the envy of your friends. Use the tips and tricks provided in this article to ensure your success and create acrylic jewelry that you'll be proud to wear and show off.

Video Display | Glance for Acrylic Laser Cutting

Recommended Laser cutter machine for acrylic

FAQ

Acrylic thickness for jewelry depends on design and cutter power. Here’s the range:

Summary: Most acrylic jewelry uses 1–5mm sheets—thicker acrylic needs more powerful cutters.

Common Range: 1–3mm is best for delicate pieces (earrings, pendants). Thicker acrylic (4–5mm) works for bold designs (bracelets).

Cutter Limitations: A 40W laser cuts up to 5mm acrylic; 80W+ cuts thicker (but jewelry rarely needs >5mm).

Design Impact: Thicker acrylic needs simpler designs—intricate patterns get lost in thick material.

Yes—vector-based software ensures laser cutters read designs correctly. Here’s what to use:

Vector Files: Laser cutters need .svg or .ai files (vector format) for precise cuts. Raster images (e.g., .jpg) won’t work—software traces them into vectors.

Free Alternatives: Inkscape (free) works for simple designs if you can’t afford Adobe/Corel.

Design Tips: Keep lines >0.1mm thick (too thin breaks during cutting) and avoid tiny gaps (traps laser heat).

Finishing ensures smooth, professional-looking edges. Here’s how:

Sanding: Use 200–400 grit sandpaper to remove laser “burn” marks.

Flame Polishing: A small butane torch lightly melts edges for a glossy finish (works best on clear acrylic).

Painting: Add color to cut-out areas with acrylic paint or nail polish for contrast.

Any questions about the operation of how to laser engrave acrylic?

Post time: Apr-06-2023