FAQ

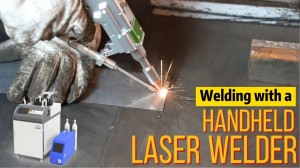

When choosing power, consider the metal type and its thickness. For thin sheets (e.g., < 1mm) of zinc galvanized steel or aluminum, a 500W - 1000W handheld laser welder like ours might be sufficient. Thicker carbon steel (2 - 5mm) usually requires 1500W - 2000W. Our 3000W model is ideal for very thick metals or high - volume production. In summary, match the power to your material and job scale for optimal results.

Safety is crucial. Always wear proper personal protective equipment (PPE), including laser - safety goggles to protect your eyes from the intense laser light. Ensure the work area has good ventilation as welding fumes can be harmful. Keep flammable materials away from the welding zone. Our handheld laser welders are designed with safety in mind, but following these general safety rules will prevent accidents. Overall, proper PPE and a safe work environment are essential for using our handheld laser welders.

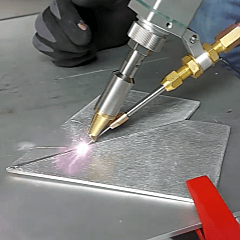

Yes, our handheld laser welders are versatile. They can weld zinc galvanized steel sheets, aluminum, and carbon steel. However, settings need adjustment for each material. For aluminum, which has high thermal conductivity, you may need higher power and faster welding speeds. Carbon steel might require different focal lengths. With our machines, fine - tuning settings according to the material type allows for successful welding across various metals.