Large Format Foam Laser Cutter

To satisfy the customers’ over-expected pleasure , we’ve our strong group to supply our greatest over-all provider which incorporates promoting, revenue, coming up with, output, quality managing, packing, warehousing and logistics for Large Format Foam Laser Cutter, Our expert complex team will likely be wholeheartedly at your services. We sincerely welcome you to definitely go to our website and company and deliver us your inquiry.

To satisfy the customers’ over-expected pleasure , we’ve our strong group to supply our greatest over-all provider which incorporates promoting, revenue, coming up with, output, quality managing, packing, warehousing and logistics for best way to cut polyurethane foam, best way to cut soft foam, can you laser cut eva foam, can you laser cut foam board, custom foam cutter, custom laser cut foam, foam cutting laser, Foam Laser Cutter, foam laser cutting machine, foam laser cutting service, how to cut polyester foam, Laser Cut Foam, laser cut foam insert, Laser Cut Mat, laser cut polyurethane foam, laser cutter foam board, laser cutter for foam board, Laser cutting foam, laser cutting foam sheets, laser foam cutter machine, laser foam cutting, mat laser cutter, polyurethane foam laser cutting, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

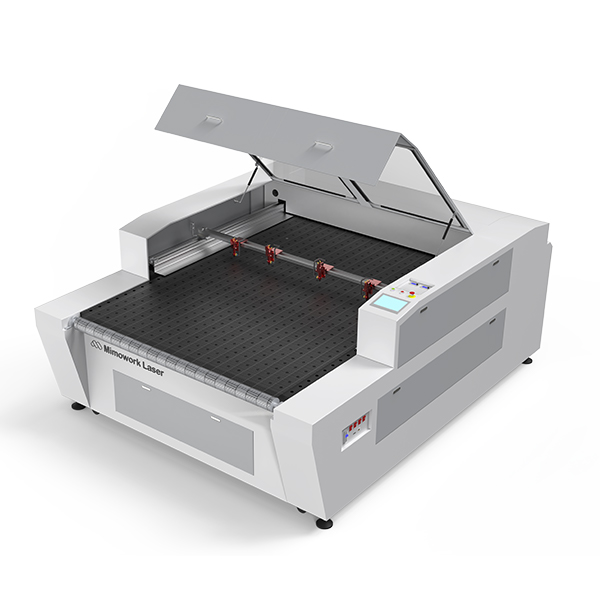

Advantages of Flatbed Laser Cutter

Marking all over your place

Technical Data

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

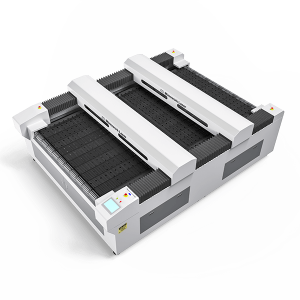

R&D for Flexible Material Cutting

Two Laser Heads

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

Video Overview of Laser Cutting & Perforating on Sandpaper

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Customized Marking

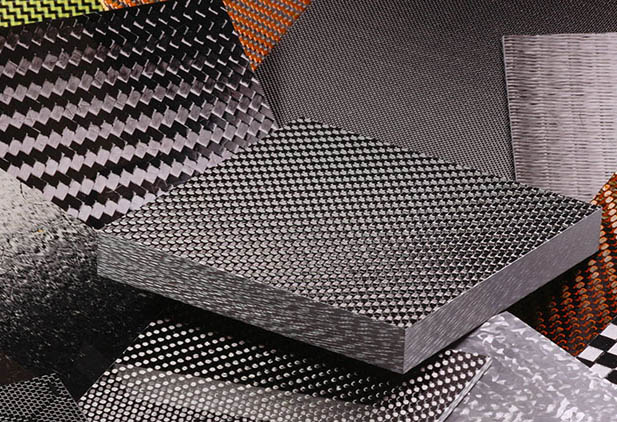

Composite Material

Engraving, marking, and cutting can be realized in single process

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Laser Cutting Foam

Professional and qualified Laser Cutting Solution for Foam

The industrial use of foam is constantly being updated. Today’s foam market is composed of many different materials used in a wide range of applications. In order to process foams, the industry is increasingly finding that laser cutter is very suitable for cutting and engraving foams made of polyester (PES), polyethylene (PE) or polyurethane (PUR). In some applications, lasers can provide an impressive alternative to traditional processing methods. In addition, laser processed foam is also used in artistic applications, such as souvenirs or photo frames.

Benefits from Laser Cutting on Foam

crisp-clean-edge

Crisp & clean edge

Fine-precise-incision

Fine & precise incision

laser-cutting-foam-shape

Flexible multi-shapes cutting

When cutting industrial foam, the advantages of laser cutter over other cutting tools are obvious. Although the traditional cutter exerts strong pressure on the foam, which results in material deformation and unclean cutting edges, the laser can create the finest contours due to precise and non-contact cutting.

When using water jet cutting, water will be sucked into the absorbent foam during the separation process. Before further processing, the material must be dried, which is a time-consuming process. Laser cutting omits this process and you can continue processing the material immediately. In contrast, the laser is very convincing and is clearly the number one tool for foam processing.

Typical applications for Laser Cutting Foam

• Foam gasket

• Foam pad

• Car seat filler

• Foam liner

• Seat cushion

• Foam Sealing

• Photo Frame

Material information of Laser Cutting Foam

Foam is a material that has been adsorbed by plastic particles, referred to as foam. Foam is divided into PU foam, bulletproof foam, conductive foam, EPE, bulletproof EPE, CR, EVA, bridging PE, SBR, EPDM, etc, widely used in life and industry.