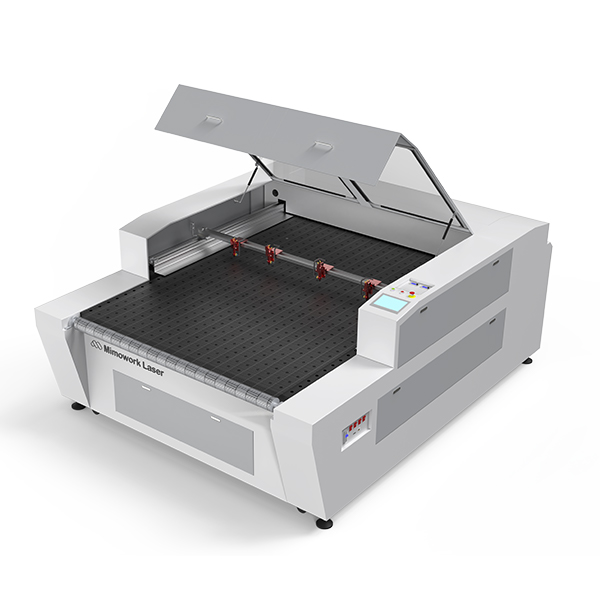

Flatbed Laser Cutter 180

◉ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Mark pen makes labor-saving process and efficient cutting & marking operations possible

◉ Upgraded cutting stability and safety - improved by adding the vacuum suction function

◉ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional)

◉ Advanced mechanical structure allows laser options and customized working table

Technical Data

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

R&D for Textile and Fabric Laser Cutting

Two Laser Heads

Video Glance

▷ How to laser cut cotton fabric

✔ Automatic feeding, conveying and cutting can be achieved

✔ Dual laser heads is optional to further enhance the efficiency

✔ Flexible cotton cutting according to the uploaded graphic file

✔ Non-contact and heat treatment ensure the clean and flat cutting quality

Find more videos about our laser cutters at our Video Gallery

▷ Cutting sandpaper with the laser cutter

Powerful laser beam release huge energy to melt the sandpaper instantly. Non-contact laser cutting avoid the touch between sandpaper and laser head, leading to clean and crisp cutting effect. Also, with the Nesting software and Mimocut software, shortest time-consuming and minimum material-waste become possible. As you can see on the video, accurate shape cutting can be consistent to complete the whole production.

Fields of Application

Laser Cutting for Your Industry

✔ Smooth and lint-free edge through heat treatment

✔ Conveyor system helps more efficient production for the roll materials

✔ High precision in cutting, marking, and perforating with fine laser beam

Engraving, marking, and cutting can be realized in single process

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Fewer material waste, no tool wear, better control of production costs

✔ Ensures a safe working environment during operation

✔ High precision in cutting, marking, and perforating with fine laser beam

From MimoWork Advice:

Roll fabric and leather products all can be laser cut and laser engraved. MimoWork provides the professional technology support and considerate reference guide. Reliable quality and caring service are the aim we are committed to. Also, evolving materials and application adaptable to laser cutting is expanding. You can find your material or application on our MimoWork Lab-Base.