Laser Cutter for Foam Board

We’ve one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for Laser Cutter for Foam Board, The crew of our corporation together with the use of cutting-edge technologies delivers impeccable high quality merchandise supremely adored and appreciated by our shoppers all over the world.

We’ve one of the most innovative manufacturing devices, experienced and qualified engineers and workers, recognized good quality handle systems and also a friendly experienced income team pre/after-sales support for custom foam cutter, custom laser cut foam, foam cutting laser, Foam Laser Cutter, foam laser cutting machine, foam laser cutting service, Laser Cut Foam, laser cut foam insert, laser cut polyurethane foam, laser cutter foam board, laser cutter for foam board, Laser cutting foam, laser foam cutter machine, laser foam cutting, polyurethane foam laser cutting, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. “Your satisfaction is our happiness”.

Technical Data

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Multifunction in One Machine

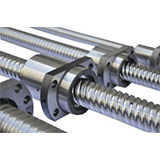

Ball & Screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional lead screws, ball screws tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. The ball screw ensures high speed and high precision laser cutting.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

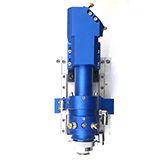

Mixed Laser Head

A mixed laser head, also known as a metal non-metallic laser cutting head, is a very important part of the metal & non-metal combined laser cutting machine. With this professional laser head, you can cut both metal and non-metal materials. There is a Z-Axis transmission part of the laser head that moves up and down to track the focus position. Its double drawer structure enables you to put two different focus lenses to cut the materials of different thicknesses without adjustment of focus distance or beam alignment. It increases cutting flexibility and makes the operation very easy. You can use different assist gas for different cutting jobs.

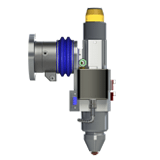

Auto Focus

It is mainly used for metal cutting. You may need to set a certain focus distance in the software when the cutting material is not flat or with different thickness. Then the laser head will automatically go up and down, keeping the same height & focus distance to match with what you set inside the software to achieve a consistently high cutting quality.

Video of Laser Cutting Acylic (PMMA)

Video of Laser Engraving Wood Board

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Digital Printing

Clean and smooth edge with thermal treatment

Advertising & Gifts

Unique advantages of laser cutting signs & decorations

Common materials and applications

of Flatbed Laser Cutter 130

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Laser Cutting Foam

Professional and qualified Laser Cutting Solution for Foam

The industrial use of foam is constantly being updated. Today’s foam market is composed of many different materials used in a wide range of applications. In order to process foams, the industry is increasingly finding that laser cutter is very suitable for cutting and engraving foams made of polyester (PES), polyethylene (PE) or polyurethane (PUR). In some applications, lasers can provide an impressive alternative to traditional processing methods. In addition, laser processed foam is also used in artistic applications, such as souvenirs or photo frames.

Benefits from Laser Cutting on Foam

Crisp & clean edge

Fine & precise incision

Flexible multi-shapes cutting

When cutting industrial foam, the advantages of laser cutter over other cutting tools are obvious. Although the traditional cutter exerts strong pressure on the foam, which results in material deformation and unclean cutting edges, the laser can create the finest contours due to precise and non-contact cutting.

When using water jet cutting, water will be sucked into the absorbent foam during the separation process. Before further processing, the material must be dried, which is a time-consuming process. Laser cutting omits this process and you can continue processing the material immediately. In contrast, the laser is very convincing and is clearly the number one tool for foam processing.

Laser processing for Foam

1. Laser Cutting on Foam

Flexible laser head with fine laser beam to melt the foam in a flash to cut off the foam to achieve sealing edges.

2. Laser Engraving on Foam

The fine laser beam etching the surface of the foam uniformly to achieve optimal engraving effect.

Typical applications for Laser Cutting Foam

• Foam gasket

• Foam pad

• Car seat filler

• Foam liner

• Seat cushion