Galvo Laser Engraver for Film

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Galvo Laser Engraver for Film, We warmly welcome pals from all walks of everyday living to cooperate with us.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for 3M film laser cutting, CO2 galvo laser, co2 galvo laser marking machine, Co2 Galvo Laser System, cost of co2 laser machine, film laser cutting, film laser cutting machine, Galvo Co2 Laser Marking Machine, Galvo Laser, galvo laser cutter, Galvo Laser Cutting, Galvo Laser Engraver, galvo laser machine price, laser cut adhesive film, laser cut polyester film, laser cut window film, laser cutter for film, laser cutting films for keyboards, laser cutting for PVC film, laser cutting heat transfer film, laser cutting of protective films, pet film laser cutting, plastic film laser cutting, polyester film laser cutting, printed film, printed vinyl film cutting, vinyl film wrap laser cut, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires remember to do not hesitate to contact us. Thank you – Your support continuously inspires us.

Advantages from Galvo Laser Engraver

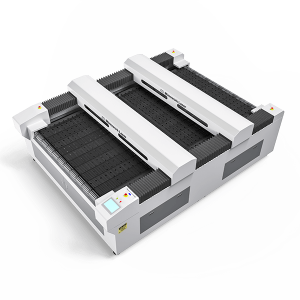

Best Entry-level GALVO Laser Machine

◉ Ultra-speed & high efficiency

Small deflection, but large action area. Flying laser marking from 3D dynamic focus declination quickly shoot the laser beam to the material, eliminating flatbed gantry moving time. Fast production timely responses the market requirements whether for customization or mass batch.

◉ Rich effect from versatile galvo laser

Besides laser engraving and marking, galvo laser can achieve cutting materials, cooperating with galvo laser engraving, to build coherent production assembly line. A multi-layered crafts from kiss-cutting is easy to realize on the paper, heat transfer film and foil.

◉ Fine details with high quality

Benefiting from deft laser path and applicable laser power, fine laser beam draw the artworks on the surface with high precision. Different diameters and heights of lens impact the ultimate effect.

◉ Safe & advanced laser structure

Enclosed laser structure provides a safe functioning space for work pieces and operator. Also, upgrade laser options are available to expand more production varieties.

(Superior Specifications for your fabric laser engraving machine, leather laser engraving machine, paper laser cutter)

Technical Data

| Working Area (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Beam Delivery | 3D Galvanometer |

| Laser Power | 180W/250W/500W |

| Laser Source | CO2 RF Metal Laser Tube |

| Mechanical System | Servo Driven, Belt Driven |

| Working Table | Honey Comb Working Table |

| Max Cutting Speed | 1~1000mm/s |

| Max Marking Speed | 1~10,000mm/s |

Highlight of GALVO Laser Engraver & Marker 40

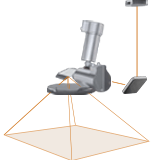

GALVO Head

GALVO laser uses high-speed, motor-driven mirrors to steer the laser beam through the lens. Aiming at the material in the laser marking and laser engraving field, the beam impacts the material at a greater or lesser inclination angle. The marking field size is defined by the deflection angle and the focal length of the optics. As there is no mechanical movement during galvo laser functioning (with the exception of the mirrors), the laser beam can be guided over the workpiece at an extremely high speed. High efficiency and at the same time, high precision, make GALVO Laser Engraver & Marker 40 an ideal marking machine when it comes to short cycle times or high-quality markings.

For other GALVO views, diverse GALVO lenses are available. The biggest GALVO laser lens for this model is up to 800mm.

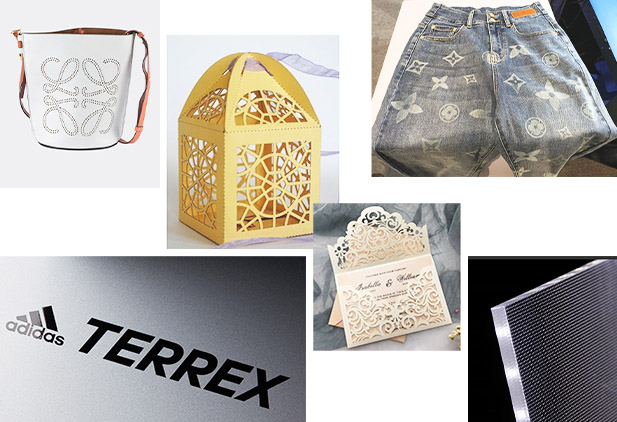

Fields of Application

Glavo CO2 Laser for Your Industry

Kiss Cutting

(A laser tech that is widely used in laser cutting film, laser cutting foil, laser engraving leather patches)

✔ Fine incision and clean surface without materials damage due to contact-less processing

✔ Minimal defective rate with digital control system

✔ Consistent processing and high repeating ensure high efficiency and quality

Common materials and applications

of GALVO Laser Engraver & Marker 40

Materials: Film, Foil, Paper, Fleece, Denim, Leather, Acrylic(PMMA), Plastic, Wood,and other Non-metal Materials

Applications: Footwear, Invitation Card, Perforated Cloth, Car Seat Perforation, Garments Accessories, Bags, Labels, Packing, Puzzles, Sportswear, Jeans, Carpets, Curtains, Technical Textiles, Air Dispersion Ducts

View more materials

View more applications

Learn more about what is a galvo, galvo laser engraving denim

Add yourself to the list!

Laser Cutting Film

Positive Solution of Laser Cutting PET Film

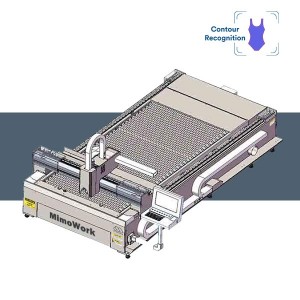

Laser cutting polyester film is the typical applications. Due to the prominent polyester performance, it is widely applied on display screen, membrane switch overlaying, touchscreen and others. Laser cutter machine opposes excellent laser melting capability on the film to produce clean & flat cut quality at high efficiency. Any shapes can be flexibly laser cut after uploading the cutting files. For printed film, MimoWork Laser recommends the contour laser cutter which can realize the accurate edge cutting along the pattern with the help of the camera recognition system.

Besides that, for heat transfer vinyl, 3M® protective film, reflective film, acetate film, Mylar film, laser cutting and laser engraving are playing important roles in these applications.

• Laser cutting transparency film

• Laser cutting printed film

Only need to upload the cutting file and set the laser parameter, the laser machine will start the non-contact cutting, with accurate cutting path and precise incision. Automatic feeding and conveying provide the a consistent and stable production for film laser cutting.

Any questions about laser cutting pet film?

Contact us

Common Applications of Laser Cutting Film

• Window Film

• Nameplate

• Touch Screen

• Electrical insulation

• Industrial Insulation

• Membrane Switch Overlays

• Label

• Sticker

• Face Shield

• Flexible Packing

• Stencils Mylar Film

film-laser-cutting-01

Nowadays film can not only be used in industrial applications such as reprographics, hot stamping film, thermal-transfer ribbons, security films, release films, adhesive tapes, and labels and decals; electrical/electronic applications such as photoresists, motor, and generator insulation, wire and cable wrap, membrane switches, capacitors, and flexible printed circuits but also be used in relatively new applications such as flat panel displays (FPDs) and solar cells, etc.

Material Properties of PET Film:

laser-cutting-pet-film

Polyester film is the main material among the all, often referred to as PET (Polyethylene Terephthalate), has outstanding physical properties for a plastic film. These include high tensile strength, chemical resistance, thermal stability, flatness, clarity, high-temperature resistance, thermal and electrical insulation properties.

Polyester film for packaging represents the largest end-use market, followed by industrial which includes flat panel displays, and electrical/electronic like reflective film, etc. These end uses account for almost the total global consumption.

The Advantages of PET Laser Cutting

Compared with conventional machining methods which are for the standard grade used like packaging applications, MimoWork puts more effort to offer PETG laser cutting solutions to the film used for optical applications and for some specialty industrial and electrical uses. The 9.3 and 10.6 micro wavelengths CO2 laser is extremely suitable for laser cutting PET film and laser engraving vinyl. With precise laser power and cutting speed settings, a crystal clear cutting edge can be achieved.

Flexible shapes cutting

Clean & crisp cut edge

Laser engraving film

✔ High precision – 0.3mm cutouts are possible

✔ No paste to the laser heads with the contact-less treatment

✔ Crisp laser cutting produces the clean edge without any adhesion

✔ High flexibility for every shape, size of film

✔ Consistent high quality relying on the auto conveyor system

✔ Appropriate laser power controls the accurate cutting for multi-layer film

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Short Lead Time for China 20W Raycus Fiber Laser Flying Cutting Engraving Marking Machine Laser Cutter, We warmly welcome pals from all walks of everyday living to cooperate with us.

Short Lead Time for China Small Fiber Laser Cutting Machine, Laser Cut, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires remember to do not hesitate to contact us. Thank you – Your support continuously inspires us.