Introduction

The 3-in-1 laser welding machine is a portable handheld device integrating cleaning, welding and cutting.

It efficiently removes rust stains through non-destructive laser technology, achieving millimeter-level precision welding and mirror-level cutting.

It is compatible with various metals such as stainless steel, aluminum and copper, and is equipped with an intelligent adjustment and safety system.

It is specially designed for workshop experts, maintenance technicians and DIY enthusiasts.

Innovate the traditional metal processing procedures to enhance efficiency and precision.

Features

Portable & Compact Design

Lightweight and easy to transport, ideal for workshops, field repairs, or tight spaces.

User-Friendly Operation

Intuitive Control Panel: Simplifies adjustments (power, frequency) for beginners and experts.

Safety Systems: Built-in alarms, protective mechanisms, and fail-safes to prevent accidents or machine damage.

Precision & Adaptability

Adjustable Power Settings: Customize intensity for cleaning, welding depth, or cutting thickness.

Wide Metal Compatibility: Works seamlessly on diverse metals (e.g., stainless steel, copper, titanium).

High-Speed Performance: Ensures rapid, consistent results, boosting productivity.

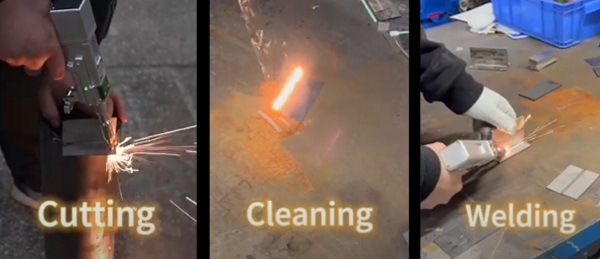

Functions

Laser Cleaning

Target Materials: Effortlessly remove rust, oil stains, and oxidation.

Key Advantage: Zero damage to the base material, preserving integrity while restoring surfaces to pristine condition.

Laser Cutting

Power Meets Finesse: Slice through sheet metal seamlessly

Key Advantage: Mirror-smooth edges eliminate the need for post-processing.

Laser Welding

Precision Redefined: Achieve paper-thin seams with industrial-strength bonds.

Key Advantage: Clean, burr-free edges ideal for delicate repairs or intricate designs.

Comparison to Traditional Method

|

Comparison Aspect |

Laser Cleaning |

Traditional Cleaning |

|

Substrate Damage |

No damage; preserves substrate integrity |

Risk of chemical corrosion or mechanical abrasion |

|

Operation |

Flexible handheld/automated modes; one-touch operation |

Relies on manual labor or heavy machinery; complex setup |

|

Accessibility |

Non-contact 360° cleaning; works in tight/curved spaces |

Limited by space |

|

Mobility |

Portable design; easy to deploy |

Fixed or heavy equipment |

Want To Know More About Laser Cutting?

Start a Conversation Now!

How to Switch Working Mode?

Three Functions

1. Click the conversion icon on the operation screen’s upper right corner.

2. Confirm to shut down and restart the system.

3. Swap the nozzle (designed for quick changes) and resume work.

No downtime. No complicated setups. Just pure productivity.

Related Videos

3 in 1 Handheld Laser Welder

This video demonstrates a remarkable three-in-one welding laser machine that integrates fiber laser cleaning, welding, and cutting into one powerful system.

It's perfect for automotive repair, metal fabrication, and industrial manufacturing, offering precision, efficiency, and versatility.

Who Would be Interested?

Shop Floor Specialists: Boost workshop efficiency with rapid task-switching and industrial-grade results.

Masters of Repairs: Tackle everything from rust removal to precision welding in one tool.

Skilled DIYers: Unleash creativity on metal projects without investing in multiple machines.

Conclusion

The 3-in-1 Handheld Laser Machine isn’t just a tool – it’s a revolution.

By merging cutting-edge laser technology with user-centric design, it redefines what’s possible in metalworking, maintenance, and DIY innovation.

Whether you’re restoring vintage car parts or crafting custom metal art, this machine delivers strength, precision, and flawless finishes – all in the palm of your hand.

Upgrade your toolkit today and experience the future of handheld laser technology.

Recommend Machines

The continuous handheld fiber laser welding machine has the ability to deep welding for some thick metal, and modulator laser power greatly improves the welding quality for high-reflective metal like aluminum alloy.

Laser power: 500W

Standard output laser power: ±2%

General Power: ≤5KW

Fiber length: 5M-10M

Humidity range of working environment: < 70%No condensation

Weld seam requirements: <0.2mm

Welding speed: 0~120 mm/s

Post time: May-06-2025