Can you Laser Cut Neoprene?

Neoprene is a type of synthetic rubber that was first invented by DuPont in the 1930s. It is commonly used in wetsuits, laptop sleeves, and other products that require insulation or protection against water and chemicals. Neoprene foam, a variant of neoprene, is used in cushioning and insulation applications.

In recent years, laser cutting has become a popular method for cutting neoprene and neoprene foam due to its precision, speed, and versatility.

Yes, We Can!

Laser cutting is a popular method of cutting neoprene due to its precision and versatility.

Laser cutting machines use a high-powered laser beam to cut through materials, including neoprene, with extreme accuracy.

The laser beam melts or vaporizes the neoprene as it moves across the surface, creating a clean and precise cut.

Laser Cut Neoprene

Laser Cut Neoprene Foam

Neoprene foam, also known as sponge neoprene, is a variant of neoprene that is used for cushioning and insulation applications.

Laser cutting neoprene foam is a popular method of creating custom foam shapes for a variety of applications, including packaging, athletic gear, and medical devices.

When laser cutting neoprene foam, it is important to use a laser cutter with a powerful enough laser to cut through the thickness of the foam. It is also important to use the right cutting settings to avoid melting or warping the foam.

Learn More about How to Laser Cut Neoprene for Clothing, Scuba Diving, Washer, ETC.

Laser Cut Leggings

Yoga pants and black leggings for women are always trending, with cutout leggings being all the rage.

Using a laser cutting machine, we were able to achieve sublimation printed sportswear laser cutting.

Laser cut stretch fabric and laser cutting fabric are what a sublimation laser cutter does best.

Benefits of Laser Cutting Neoprene

Over traditional cutting methods, laser cutting neoprene offers a number of benefits, including:

1. Precision

Laser cutting neoprene allows for precise cuts and intricate shapes, making it ideal for creating custom foam shapes for a variety of applications.

2. Speed

Laser cutting is a fast and efficient process, allowing for quick turnaround times and high-volume production.

3. Versatility

Laser cutting can be used to cut a wide range of materials, including neoprene foam, rubber, leather, and more. With one CO2 laser machine, you can process different non-metal material at once.

4. Cleanliness

Laser cutting produces clean, precise cuts with no rough edges or fraying on neoprene, making it ideal for creating finished products, such as your scuba suits.

Tips for Laser Cutting Neoprene

When laser cutting neoprene, it is important to follow a few tips to ensure a clean and precise cut:

1. Use The Right Settings:

Use the recommended laser power, speed, and focus settings for neoprene to ensure a clean and precise cut.

Also, if you want to cut thick neoprene, it’s suggested to change a large focus lens with longer focus height.

2. Test The Material:

Test the neoprene before cutting to ensure that the laser settings are appropriate and to avoid any potential issues. Start with 20% power setting.

3. Secure The Material:

Neoprene can curl or warp during the cutting process, so it is important to secure the material to the cutting table to prevent movement.

Don’t forget to turn on the exhaust fan for fixing Neoprene.

4. Clean The Lens:

Clean the laser lens regularly to ensure that the laser beam is focused properly and that the cut is clean and precise.

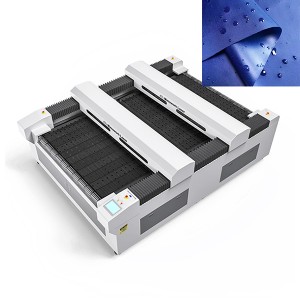

Recommended Fabric Laser Cutter

Click for the parameters and more information

FAQs

The key differences lie in parameter settings and handling details:

- Neoprene foam: It has a more porous, low-density structure and is prone to expansion or shrinkage when heated. Laser power should be reduced (typically 10%-20% lower than for solid neoprene), and cutting speed increased to prevent excessive heat buildup, which could damage the foam structure (e.g., bubble rupture or edge collapse). Extra care must be taken to secure the material to prevent shifting due to airflow or laser impact.

- Solid neoprene: It has a denser texture and requires higher laser power to penetrate, especially for materials over 5mm thick. Multiple passes or a long-focal-length lens (50mm or more) may be needed to expand the laser’s effective range and ensure complete cutting. Edges are more likely to have burrs, so optimizing speed (e.g., medium speed paired with medium power) helps achieve smoother results.

- Complex shape customization: For example, curved seams in wetsuits or 镂空 ventilation holes in sports protective gear. Traditional blade cutting struggles with precise curves or intricate patterns, while lasers can replicate designs directly from CAD drawings with an error margin of ≤0.1mm—ideal for high-end custom products (e.g., body-conforming medical braces).

- Bulk production efficiency: When producing 100 neoprene gaskets of the same shape, traditional blade cutting requires mold preparation and takes ~30 seconds per piece. Laser cutting, by contrast, operates continuously and automatically at speeds of 1-3 seconds per piece, with no need for mold changes—perfect for small-batch, multi-style e-commerce orders.

- Edge quality control: Traditional cutting (especially with blades) often leaves rough, wrinkled edges requiring additional sanding. Laser cutting’s high heat slightly melts edges, which then cool quickly to form a smooth "sealed edge"—directly meeting finished product requirements (e.g., waterproof seams in wetsuits or insulating gaskets for electronics).

- Material versatility: A single laser machine can cut neoprene of varying thicknesses (0.5mm-20mm) by adjusting parameters. In contrast, water jet cutting tends to deform thin materials (≤1mm), and blade cutting becomes 费力且 imprecise for thick materials (≥10mm).

Key parameters and adjustment logic are as follows:

- Laser power: For 0.5-3mm thick neoprene, power is recommended at 30%-50% (30-50W for a 100W machine). For 3-10mm thick materials, power should be increased to 60%-80%. For foam variants, reduce power by an additional 10%-15% to avoid burning through.

- Cutting speed: Proportional to power—higher power allows faster speeds. For example, 50W power cutting 2mm thick material works well at 300-500mm/min; 80W power cutting 8mm thick material should slow to 100-200mm/min to ensure sufficient laser penetration time.

- Focal length: Use a short-focal-length lens (e.g., 25.4mm) for thin materials (≤3mm) to achieve a small, precise focal spot. For thick materials (≥5mm), a long-focal-length lens (e.g., 50.8mm) expands the laser’s range, ensuring deep penetration and complete cutting.

- Testing method: Start with a small sample of the same material, testing at 20% power and medium speed. Check for smooth edges and charring. If edges are over-charred, reduce power or increase speed; if not fully cut, increase power or decrease speed. Repeat testing 2-3 times to finalize optimal parameters.

Yes, laser cutting neoprene releases small amounts of harmful gases (e.g., hydrogen chloride, trace VOCs), which may irritate the respiratory system with prolonged exposure. Strict precautions are necessary:

- Ventilation: Ensure the workspace has a high-powered exhaust fan (airflow ≥1000m³/h) or dedicated gas treatment equipment (e.g., activated carbon filters) to vent fumes outdoors directly.

- Personal protection: Operators must wear laser safety goggles (to block direct laser exposure) and gas masks (e.g., KN95 grade). Avoid direct skin contact with cut edges, as they may retain residual heat.

- Equipment maintenance: Regularly clean the laser head and lenses to prevent smoke residue from impairing focus. Inspect exhaust ducts for blockages to ensure unobstructed airflow.

Want To Know More about Our How To Laser Cut Neoprene?

Post time: Apr-19-2023