How to Cut Kevlar Vest?

Kevlar is widely known for its incredible strength and durability, making it a popular choice for a variety of applications, including protective clothing like vests. But is Kevlar truly cut-resistant, and how can you use a fabric laser cutting machine to create a Kevlar vest?

Is Kevlar Cut-Resistant?

Yes.Kevlar is a highly durable material that is designed to be resistant to cuts and punctures. The material is made up of long, interlocking fibers that are tightly woven together, creating a tough and flexible structure. These fibers are incredibly strong, with a tensile strength that is five times greater than steel. This makes Kevlar an ideal choice for applications that require high levels of protection against cutting and piercing.

However, while Kevlar is highly resistant to cuts and punctures, it is not completely cut-proof. It is still possible to cut through Kevlar with a sharp enough blade or tool, especially if the material is worn or damaged. This is why it is important to choose a high-quality Kevlar fabric and ensure that it is properly maintained to ensure its protective properties.

How to Cut a Kevlar Vest Using a Fabric Laser Cutting Machine?

When it comes to creating a Kevlar vest, a fabric laser cutting machine can be a highly effective tool. Laser cutting is a precise and efficient method that allows you to cut through multiple layers of fabric at once, creating clean and accurate cuts with minimal fraying or damage to the material.

You can check out the video to have a glance at laser cutting fabric.

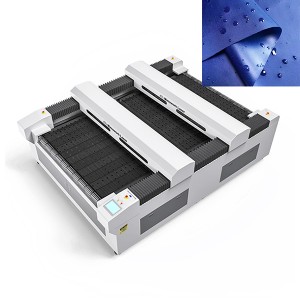

Auto Feeding Laser Cutting Machine

This automated CO2 laser cutting machine delivers fast, precise cutting and engraving for fabrics like cotton and leather. It streamlines production with automatic operation, providing designers and manufacturers an efficient tool to easily create custom projects.

How to Laser Cut Tactical Gear

This video shows how to laser cut a Cordura vest, explaining why a laser machine is the perfect tool for this task. You'll see the basic steps and learn how non-contact laser cutting preserves the fabric's durability and strength.

To cut a Kevlar vest using a fabric laser cutting machine, follow these steps:

1. Choose your Kevlar fabric

Look for a high-quality Kevlar fabric that is designed specifically for use in protective clothing like vests. Make sure that the fabric is the right weight and thickness for your needs.

2. Prepare the fabric

Before cutting, make sure that the fabric is clean and free of any debris or loose fibers. You may also want to apply a masking tape or another protective material to the surface of the fabric to prevent scorching or burning during the cutting process.

3. Set up the laser cutter

Adjust the settings on your fabric laser cutting machine to ensure that it is properly configured for cutting Kevlar. This may involve adjusting the focus, power, and speed of the laser to ensure that it is cutting cleanly and accurately through the material.

4. Cut the fabric

Once your laser cutter is properly configured, you can begin cutting the Kevlar fabric. Make sure to follow the manufacturer's instructions for using the laser cutter and wear appropriate protective gear, including eye protection.

5. Assemble the vest

After cutting your Kevlar fabric, you can assemble it into a protective vest. This may involve sewing or bonding the fabric together using specialized techniques and materials.

Any Questions about How to Cut Kevlar Vest with the Fabric Laser Cutter

Why Choose Laser Cutting Kevlar?

Advantages of Laser Cutting Kevlar:

Contactless Processing:

The laser beam cuts without physical force, eliminating tool wear and material distortion.

Sealed, Fused Edges:

The laser's heat instantly melts the fiber ends, creating a perfectly sealed edge. This is the most critical advantage, preventing fraying and maintaining material strength.

Unmatched Precision & Flexibility:

Cut any complex 2D shape with razor-sharp accuracy from a digital file, enabling advanced ergonomic designs and integrated vent patterns.

Automation & Efficiency:

When integrated with an auto-feeding system, the machine can process large sheets or roll materials continuously, dramatically boosting output.

Technology Comparison:

| Feature | Laser Cutting | Die Cutting / Blade |

|---|---|---|

| Edge Quality | Sealed, fused, no fraying | Frayed, requires sealing |

| Tooling Cost | None (no physical tool) | High (custom dies, frequent replacement) |

| Design Change | Instant (digital file) | Slow, costly (new die) |

| Complexity | Unlimited 2D shapes | Very limited |

| Automation Level | High (auto-feed possible) | Low to medium |

| Setup Time | Minutes | Hours |

Seeing is believing. Watch this direct comparison between CO₂ laser cutting and traditional scissors to witness how laser technology delivers perfectly sealed edges in a single, contactless process.

Related Video:

Fabric Cutting Machine | CO2 Laser vs Scissor

In this video, we provide a direct comparison between manual cutting, mechanical cutting, and CO2 laser fabric cutting.

Ready to transform your Kevlar manufacturing process?

Contact Our Laser Experts for a Personalized Consultation

Applications of Laser Cutting Kevlar

The precision and edge-sealing capabilities of laser cutting unlock new possibilities across industries that rely on high-performance fabrics:

Personal & Tactical Armor Manufacturing:

Ballistic & Stab Vests: Precisely cut complex, multi-curve panels for optimal ergonomic fit and weight distribution. Integrated cutting of ventilation holes enhances wearer comfort.

Helmets & Protective Inserts: Cut advanced shock-absorbing padding layers (often combining Kevlar with other foams) with perfect accuracy for seamless assembly.

High-Performance Safety Gear:

Cut-Resistant Gloves & Sleeves: Produce intricate patterns for superior dexterity without fraying, ensuring long-lasting protection in industrial and culinary settings.

Firefighting & Heat Protection Gear: Accurately cut composite materials for turnout gear, ensuring reliability in critical situations.

Aerospace & Automotive Composites:

Interior Panels & Reinforcement: Cut lightweight Kevlar-based composites for cabin interiors, trim, or structural reinforcements with flawless edges, ready for bonding or molding.

Racing Components: Manufacture custom protective panels, under-body shielding, or lightweight interior parts for motorsports with rapid prototyping capabilities.

Technical Apparel & Sports Equipment:

High-End Sportswear: Incorporate durable Kevlar reinforcements in high-abrasion areas (knees, shoulders) of outdoor apparel or motorcycle gear with clean, aesthetic finishes.

Equipment & Bags: Cut durable fabric for premium backpacks, sailing components, or protective cases where strength-to-weight ratio is crucial.

Recommended Fabric Laser Cutting Machines

Conclusion

Kevlar is a highly durable material that is resistant to cuts and punctures, making it an ideal choice for protective clothing like vests. While it is not completely cut-proof, it offers a high level of protection against cutting and piercing. By using a fabric laser cutting machine, you can create clean and accurate cuts in Kevlar fabric, allowing you to create highly effective and durable protective vests. Remember to choose a high-quality Kevlar fabric and properly maintain it to ensure its protective properties.

Related Materials & Applications of Laser Cutting

Want to know more about laser cutting Kevlar fabric?

Post time: May-11-2023