Why Acrylic Always Comes to Mind

When Laser Cutting and Engraving?

When it comes to laser cutting and engraving, one material that immediately comes to mind is acrylic. Acrylic has gained immense popularity in the realm of laser technology due to its unique properties and versatility. From intricate designs to functional prototypes, there are several reasons why acrylic is the go-to material for laser cutting and engraving.

▶ Exceptional Clarity and Transparency

Acrylic sheets possess a glass-like quality, allowing laser beams to pass through with precision. This transparency opens up a world of creative possibilities, enabling artists, designers, and engineers to produce stunning and intricate designs. Whether it's a delicate art piece, signage, or decorative accents, laser cutting acrylic allows for the creation of intricate and visually appealing designs that capture attention and leave a lasting impression.

What other Advantages does Acrylic have?

▶ Versatility in terms of Color and Finish Options

Acrylic sheets are available in a wide range of vibrant colors, including translucent, transparent, and opaque variations. This versatility allows for endless design possibilities, as different colors and finishes can be combined to create visually striking effects. Additionally, acrylic can be easily painted or coated to further enhance its aesthetic appeal, making it an ideal choice for creating personalized and customized pieces.

▶ Durable and Resilient

Acrylic is also a durable and resilient material, making it suitable for a variety of applications. Laser cutting acrylic produces clean and precise edges, ensuring the finished product has a professional and polished appearance. Unlike other materials that may warp or degrade under high heat, acrylic retains its shape and integrity, making it perfect for functional prototypes, signage, and architectural models. Its durability also ensures that the engraved or cut designs withstand the test of time, providing long-lasting beauty and functionality.

▶ Ease of Maintenance and Handling

It is lightweight, making it easy to transport and work with. Acrylic sheets are resistant to scratches and fading, ensuring that the engraved or cut designs maintain their clarity and brilliance over time. Additionally, cleaning and maintaining acrylic surfaces is a breeze, requiring only a soft cloth and mild cleaning agents.

Video Demonstration of Laser Cutting and Engraving Acrylic

Laser Cut 20mm Thick Acrylic

Cut & Engrave Acrylic Tutorial

Making a Acrylic LED Display

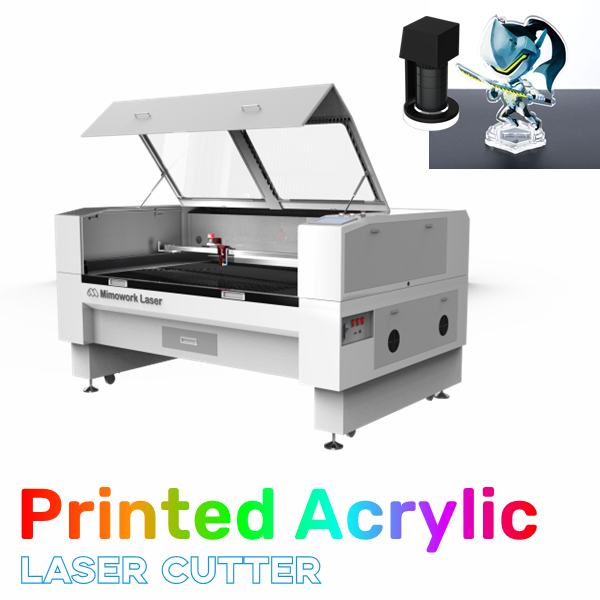

How to Cut Printed Acrylic?

In Conclusion

Acrylic is the material that first comes to mind when it comes to laser cutting and engraving due to its transparency, versatility, durability, and ease of use. Laser-cutting acrylic allows for the creation of intricate and visually stunning designs, while its durability ensures long-lasting beauty and functionality. With Mimowork's laser cutters and engravers, artists, designers, and engineers can unleash their creativity and achieve exceptional results when working with acrylic.

Want to Get a Head Start?

What About These Great Options?

Want to get Started with a Laser Cutter& Engraver Right Away?

Contact Us for Inquire to get Started Right Away!

▶ About Us - MimoWork Laser

We Don't Settle for Mediocre Results

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20-year deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

Our rich experience of laser solutions for metal and non-metal material processing is deeply rooted in worldwide advertisement, automotive & aviation, metalware, dye sublimation applications, fabric and textiles industry.

Rather than offering an uncertain solution that requires purchase from unqualified manufacturers, MimoWork controls every single part of the production chain to make sure our products have constant excellent performance.

MimoWork has been committed to the creation and upgrade of laser production and developed dozens of advanced laser technology to further improve clients' production capacity as well as great efficiency. Gaining many laser technology patents, we are always concentrating on the quality and safety of laser machine systems to ensure consistent and reliable processing production. The laser machine quality is certificated by CE and FDA.

MimoWork Laser System can laser cut Acrylic and laser engrave Acrylic, which allows you to launch new products for a wide variety of industries. Unlike milling cutters, engraving as a decorative element can be achieved within seconds by using a laser engraver. It also gives you the opportunity to take orders as small as one single unit customized product, and as large as thousands of rapid productions in batches, all within affordable investing prices.

Get More Ideas from Our YouTube Channel

Post time: Jun-26-2023