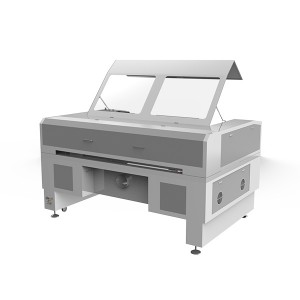

Plastic CO2 Laser Cutting Machine

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for Plastic CO2 Laser Cutting Machine, We’ve been glad that we have been steadily escalating using the energetic and long lasting assist of our pleased shoppers!

We have been also concentrating on enhancing the things management and QC method so that we could preserve terrific edge inside the fiercely-competitive enterprise for custom plastic cutting, cutting plastic with laser, laser cut plastic sheets, laser cut polyethylene, laser cut polypropylene, laser cutter for plastics, laser cutting plastic, laser engrave on plastic, laser engraver for plastic, laser etching on plastic, laser marking plastic, plastic laser engraver, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers’ faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end items, to do professional products and solutions.

Technical Data

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Software |

Offline Software |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

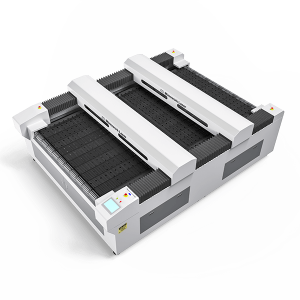

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

2050mm * 1650mm * 1270mm (80.7” * 64.9” * 50.0”) |

|

Weight |

620kg |

Multifunction in One Machine

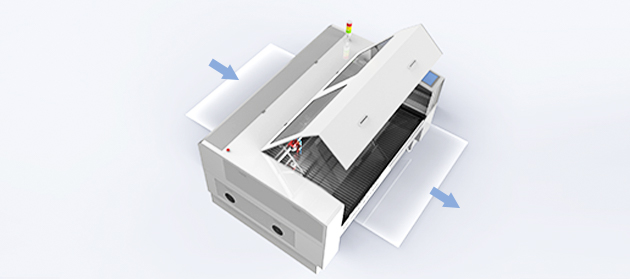

Two-way Penetration Design

Laser engraving on the large format acrylic can be realized easily thanks to the two-way penetration design, which allows acrylic panels placed through the whole width machine, even beyond the table area. Your production, whether cutting and engraving, will be flexible and efficient.

Stable and Safe Structure

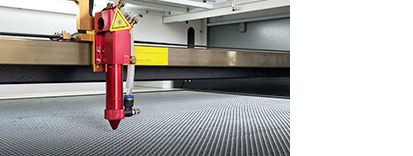

◾ Air Assist

Air assist can clean off the fume and particles generated during plastic cutting and engraving. And the blowing air can help to reduce the heat affected area resulting in the clean and flat edge without extra material melt. Timely blowing off the waste can protect the lens from damage to extend the service life. Any questions about air adjustment to consult us.

◾ Enclosed Design

Enclosed design provides a safe and clean work environment without fume and odor leaks. You can monitor the plastic cutting condition through the window, and control it by the electronic panel and buttons.

◾ Safe Circuit

Smooth operation makes a requirement for the function-well circuit, whose safety is the premise of safety production.

◾ CE Certification

Owning the legal right of marketing and distributing, MimoWork Laser Machine has been proud of its solid and reliable quality.

Upgrade options for you to choose

DC Brushless Motors

Brushless DC (direct current) motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. The brushless dc motor is rarely seen in a CO2 laser cutting machine. This is because the speed of cutting through a material is limited by the thickness of the materials. On the contrary, you only need small power to carve graphics on your materials, A brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

Rotary Attachment

If you want to engrave on the cylindrical items, the rotary attachment can meet your needs and achieve a flexible and uniform dimensional effect with a more precise carved depth. Plugin the wire into the right places, the general Y-axis movement turns into the rotary direction, which solves the unevenness of engraved traces with the changeable distance from the laser spot to the round material’s surface on the plane.

Fume Filter

Some fume and particles from plastic burned during laser cutting may be troublesome for you and the environment. Fume filter combined with ventilation system (exhaust fan) helps to absorb and clean the annoying gas effluent.

CCD Camera

The CCD Camera can recognize and position the pattern on the printed plastic, assisting laser cutter to realize accurate cutting with high quality. Any customized graphic design printed can be flexibly processed along the outline with the optical system, playing an important part in advertising and other industry.

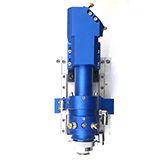

Mixed Laser Head

A mixed laser head, also known as a metal non-metallic laser cutting head, is a very important part of the metal & non-metal combined laser cutting machine. With this professional laser head, you can cut both metal and non-metal materials. There is a Z-Axis transmission part of the laser head that moves up and down to track the focus position. Its double drawer structure enables you to put two different focus lenses to cut the materials of different thicknesses without adjustment of focus distance or beam alignment. It increases cutting flexibility and makes the operation very easy. You can use different assist gas for different cutting jobs.

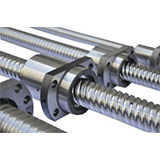

Ball & Screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional lead screws, ball screws tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. The ball screw ensures high speed and high precision laser cutting.

Acrylic Samples of laser engraving

Pictures Browse

Material Information

- Typical applications

- Compatible materials you can refer to:

Any questions about plastic laser cutting & engraving

Related Laser Machine

▶ Plastic cutting & engraving

Customize plastic items with varied sizes, shapes and materials

Flatbed Laser Cutter 100

• Working Area (W *L): 1000mm * 600mm

• Laser Power: 40W/60W/80W/100W

▶ Plastic marking

Suitable for plastic marking (series number, QR code, logo, text, identification)

We’ve designed laser systems for dozens of clients

Add yourself to the list!

One of Hottest for China Laser Cutting Machine, Cheap Cutting Machine, We taking advantage of experience workmanship, scientific administration and advanced equipment, ensure the product quality of production, we not only win the customers’ faith, but also build up our brand. Today, our team is committed to innovation, and enlightenment and fusion with constant practice and outstanding wisdom and philosophy, we cater to the market demand for high-end items, to do professional products and solutions.

Laser Cutting Plastic

Benefits from Laser Cutting Plastic

Clean & smooth edge

Flexible internal-cut

Pattern contour cutting

✔ Minimum heat affected area only for the incision

✔ Brilliant surface due to the contactless and forceless processing

✔ Clean and flat edge with the steady and powerful laser beam

✔ Accurate contour cutting for the patterned plastic

✔ Fast speed and automatic system greatly improve the efficiency

✔ High repeated accuracy and fine laser spot ensures consistent high quality

✔ No tool replacement for customized shape

✔ Laser Marking Machine brings intricate patterns and detailed marking

Laser Processing for Plastic

1. Laser Cutting Plastic

Ultra-speed and the sharp laser beam can cut through the plastic instantly. Flexible movement with an X-Y axis structure helps laser cutting in all directions without shapes limitation. Internal cut and curve cut can be easily realized below one laser head.

2. Laser Engraving on plastic

A raster image can be laser engraved on the plastic. Changing laser power and fine laser beam build up the different engraved depths to present lively visual effects.

3. Laser Marking on plastic

Only with the lower laser power, the fiber laser machine can etch and mark on the plastic with permanent and clear identification. You can find the fine score on some electronic parts, tags, business cards, PCB.

Material information of Laser Cutting Polyester

Plastic has been permeated into all-around applications from daily items, commodity rack, and packing, to medical storer and precise electronic parts. Just since super performance like heat-resistance, anti-chemical, lightness, and flexible-plasticity, the demands for output and quality are increasingly growing. To meet that, laser cutting technology is ever-developing to adapt to the production of plastic in varied materials, shapes, and sizes. Due to the compatibility between the laser wavelength and plastic absorbance, the laser cutter shows technology versatility of cutting, engraving, and marking on the plastic.

The CO2 laser machine can help with plastic cutting and engraving easily to result in flawless finishing. Fiber laser and UV laser are playing important roles in plastic marking, like identification, logo, code, number on the plastic.