Coated Fabric Laser Cutting Machine with Extension Table

Sticking to the principle of “Super Quality, Satisfactory service” ,We are striving to be a good business partner of you for Coated Fabric Laser Cutting Machine with Extension Table, Our enterprise has been devoting that “customer first” and committed to helping shoppers expand their business, so that they become the Big Boss !

Sticking to the principle of “Super Quality, Satisfactory service” ,We are striving to be a good business partner of you for Coated fabric laser cutter, coated fabric laser cutting, Fabric Laser Cutter Machine, fabric laser cutting, fabric pattern cutting machine, industrial fabric laser cutting machine, laser cloth cutter, laser cut on fabric, laser engrave fabric, laser etch fabric, Textile Laser Cutting Machine, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

Advantages of Flatbed Laser Cutter

A Giant Leap in Productivity

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Collecting Area (W * L) | 1600mm * 500mm (62.9” * 19.7”) |

| Software | Offline Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive / Servo Motor Drive |

| Working Table | Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Multiple Laser Head option available

R&D for Flexible Material Cutting

Two Laser Heads – Option

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

Nesting Software – Option

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

Fume Extractor – Option

Melting the surface of the material to achieve the perfect cutting result, CO2 laser processing may generate lingering gases, pungent odor, and airborne residues when you are cutting synthetic chemical materials and the CNC router can’t deliver the same precision that laser does. MimoWork Laser Filtration System can help one puzzle out the bothersome dust and fumes while minimizing disruption to production.

2-min Overview of Laser Cutting Felt

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Clothing & Home Textiles

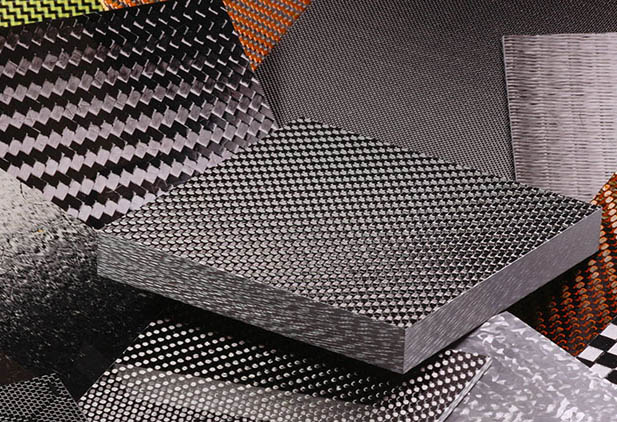

Composite Material

Engraving, marking, and cutting can be realized in single process

Automotive & Aviation

Your popular and wise manufacturing direction

Outdoor Equipment

The secret of exquisite pattern cutting

Common materials and applications

of Flatbed Laser Cutter 160

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Allow us to join hands to create a brilliant tomorrow! We are looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

Laser Cutting Coated Fabric

Professional Laser Cutting Solution for Coated Fabric

Coated fabrics are those that have undergone a coating procedure to become more functional and hold the added properties, such as cotton fabrics becoming impermeable or waterproof. Coated textiles are used in a variety of applications, including blackout curtains and the development of waterproof fabrics for raincoats.

The key point for coated fabrics cutting is the adhesion between the coating and substrate material may be damaged during cutting. Fortunately, characterized by non-contact and forceless processing, the laser cutter can cut through the coated fabrics without any materials distortion and damage. Facing different formats and varieties of coated fabrics, MimoWork explores customized laser machines and laser options for diverse production demands.

Benefits from Laser Cutting Coated Fabric

coated-fabric-clean-edge

Clean & smooth edge

clean-eage-cutting-01

Flexible shapes cutting

✔ Sealed edge from thermal treatment

✔ No deformation and damage on fabric

✔ Flexible cutting any shape and size

✔ No mold replacing and maintenance

✔ Precise cutting with the fine laser beam and digital system

Added Value from MimoWork Laser

◾ Continuous feeding and cutting with the auto-feeder and conveyor system.

◾ Customized working tables are suitable for varied sizes and shapes.

◾ Upgrade to multiple laser heads for higher efficiency and output.

◾ Extension table is convenient for collecting finished fabric.

◾ No need to fix the fabric with the strong suction from vacuum table.

◾ Pattern fabric can be contour cut due to the vision system.

Typical applications for coated fabric laser cutting

• Tent

• Outdoor equipment

• Raincoat

• Umbrella

• Industrial fabric

• Awning

• Curtain

• Working cloth

• PPE (Personal Protective Equipment)

• Fire-proof suit

• Medical equipment

Material information of Laser Cutting Coated Fabric

Coated fabrics are widely used in pristine clothes, PPE kits, aprons, coveralls, and gowns for healthcare workers usable in viral diseases such as COVID-19, medical textiles with protecting properties, body fluid resistance, and antimicrobial surface and coated fabrics also contribute to fire-retardant fabrics.

No contact cutting on coated fabric avoids material distortion and damage. Also, MimoWork laser systems provide customers suitable customized laser solutions for different requirements.