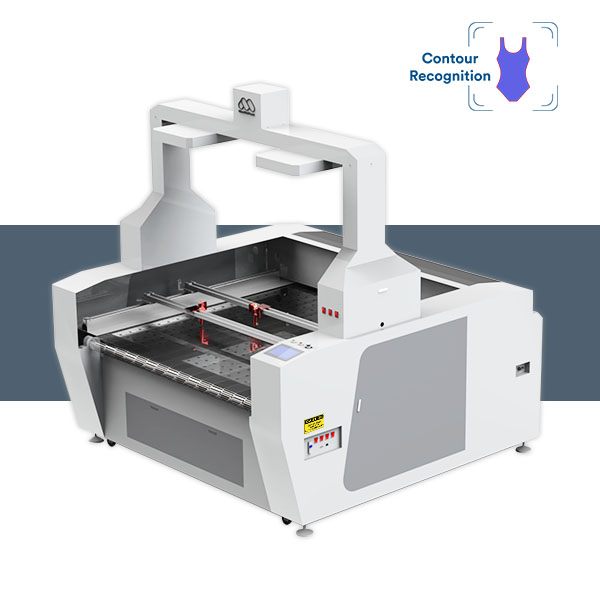

Polyester Laser Cutter with HD Camera

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Polyester Laser Cutter with HD Camera, We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We have been ready to share our knowledge of internet marketing worldwide and recommend you suitable merchandise at most aggressive rates. So Profi Tools present you very best price of money and we are ready to develop alongside one another with Automated fabric cutting machine, Automatic fabric cutting machine, Banner cutter, Digital fabric cutting machine, Digital Laser Cutting Machine, Flag cutter, Large format cutting machine, Larger format cutter, Lase engraver with camera, Laser applique cutting machine, Laser cutter for sublimation, Sign making, Smart vision camera, Sublimated sportswear, Sublimation cutter, Sublimation cutting, Sublimation laser, sublimation laser cutter, Sublimation Laser Cutting, Sublimation laser cutting machine, Sublimation printer and cutter, Sublimation sportswear, Textile Laser Cutting Machine, Vision cuts, Vision Laser Cutter, Vision laser engraver, Vision laser engraving machine, Vision laser machine, Vison laser cutting machine, Wide format cutter, Wide laser, Our company is working by the operation principle of “integrity-based, cooperation created, people oriented, win-win cooperation”. We hope we can have a friendly relationship with businessman from all over the world.

A Giant Leap from Digital Sublimation Laser Cutting Machine

Best choice for cutting large-format printed fabrics

Technical Data

| Working Area (W *L) | 1800mm * 1300mm (70.87’’ * 51.18’’) |

| Max Material Width | 1800mm / 70.87’’ |

| Laser Power | 100W/ 130W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Dual-Laser-Heads option is avaliable

D&R for flexible fabric sublimation laser cutting

60 Seconds Overview of Laser Cutting Elastic Fabrics

Find more videos about our laser cutters at our Video Gallery

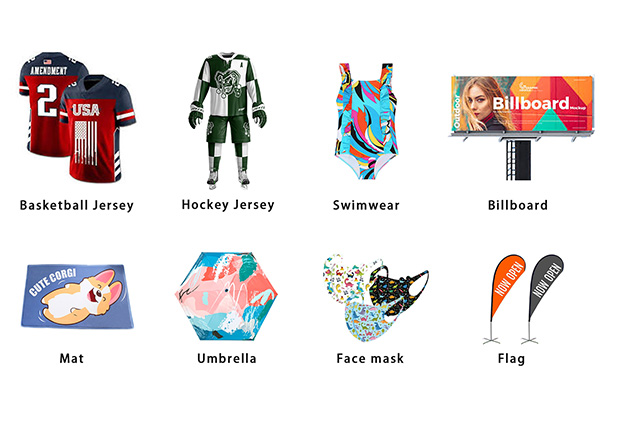

Fields of Application

Laser Cutting for Your Industry

Dye-Sublimation Sportswear, Polyester Laser Cutter

Cutting from the printed roll directly

Banners & Displays

Your popular and wise manufacturing direction

Common materials and applications

of Contour Laser Cutter 180L

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Laser Cut Polyester

Professional and qualified Laser Cutting Solution for Polyester

polyester-02

Varied Working Tables and optional Contour Recognition Systems contribute to laser cutting varieties of polyester fabric items, whether any size, any shape, any printed pattern. Not only that, a laser cutter can get rid of worries for material distortion and damage. With the reasonable layout and precise cutting, the Laser Cutter helps to maximize cost savings of raw material and processing.

Just like the wide application and development of polyester in clothing, sportswear, industrial fabrics, laser cutting technology is keeping the pace, optimizing processing methods, broadening the applicability of processing materials.

Recommended Fabric Laser Cutting Machine for Polyester

Contour-Laser-Cutter-160L-01

Vision Laser Cutter 160L

Laser cutter for dye sublimation sportswear

• Laser Power: 100W/ 130W/ 150W

• Working Area: 1600mm * 1200mm (62.9” * 47.2”)

Flatbed-Laser-Cutter-160

Polyester Laser Cutter with Collecting Area

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 1000mm (62.9” * 39.3 ”)

• Extended Collecting Area: 1600mm * 500mm

Flatbed-Laser-Cutter-160L

Large Format Polyester Laser Cutter

• Laser Power: 150W/300W/500W

• Working Area: 1600mm * 3000mm (62.9’’ *118’’)

Laser Systems Glance

Laser processing for Polyester

laser-cutting-Polyester-01

1. Laser Cutting Polyester

Fine and smooth cut, clean and sealed edge, free of shape and size, the remarkable cutting effect can be achieved perfectly by laser cutting. And the high quality and swift laser cutting eliminate post-processing, improving efficiency while saving costs.

2. Laser Marking on Polyester

Fine laser beam, coordinating with automatic digital control bring swift & subtle laser marking on polyester. Permanent mark didn’t wear or disappear. You can decorate home textiles or put marks to identify unique clothing.

laser-perforating-Polyester-01

3. Laser Perforating Polyester

Fine laser beam owns swift and deft movement pace to melt the small holes various diamester accurately and fastly. You will get tidy and clean hole edges without any materials damage.

Benefits from Laser Cutting Polyester

polyester-edge-01

Clean and flat edge

polyester-circullar-cutting-01

Any-angle circular cutting

polyester-high-efficiency-01

High efficiency & output

✔ Clean and flat edges and no materials damage

✔ Accurate contour cutting with Contour Recognition System

✔ High efficiency with continuous auto-feeding

✔ Suitable for cutting any printed pattern and shape

✔ CNC automatic control system, saving labor and time cost

✔ High repeated accuracy, ensuring consistent high quality

✔ No tool abrasion and replacing

✔ Eco-friendly processing method

Typical applications for Laser Cutting Polyester

• Sportswear

• Carpet

• Mat

• Film & Foil

• Polyester vinyl

• Felt

• Conveyor belt fabrics

• Seat belts

• Fashion and home textiles

• Coats and anoraks

• Bedding (duvet covers, and sleeping bags)

• Soft furnishings and upholstery

• Textiles

• Luggage and other bags

• Plastic reinforcement

polyester-03

Material information of Laser Cutting Polyester

polyester-10

As a generic term for artificial polymer, polyester(PET) now often is regarded as a functional synthetic material, occurring on the industry and commodity items. Made of polyester yarns and fibers, woven and knitted polyester is characterized by inherent properties of resistance to shrinking and stretching, wrinkle resistance, durability, easy cleaning, and dying. Combined blending technology with various natural and synthetic fabrics, polyester is given more traits to enhance customers’ wearing experience, improve industrial textiles’ functions. Such as cotton-polyester with high strength, weather resistance, comfortable and breathable, anti-static which is usually raw material of daily clothing and sportswear. Also, industrial applications are very common, like conveyor belt fabrics, seat belts, polyester felt.

Suitable processing technology can give full play to the excellent characteristics of polyester. The laser system has always been the first choice for polyester processing, whether it is clothing industry, home textile industry, soft interior decoration, shoe material industry, or mechanical processing, high-end technology industry, laser cutting, laser marking and laser perforating on polyester from MimoWork Laser Cutter help to improve processing efficiency and explore more possibilities on materials application and customization for you.

Other terms of polyester

- Dacron

- Terylene

- PET