Nylon Fabric Laser Cutter Machine

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Nylon Fabric Laser Cutter Machine, We consider you will be contented with our fair rate, good quality items and fast delivery. We sincerely hope you can give us an option to serve you and be your ideal partner!

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Co2 laser stippling, how to cut nylon, how to laser engrave polymer, laser cut nylon sheet, Laser cutting nylon, Laser cutting pa, nylon cutter, Nylon cutter machine, nylon cutting, Nylon cutting machine, nylon laser cutting, nylon sheet cut to size, Corporate goal: Customers’ satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Advantages of Textile Laser Cutting Machine

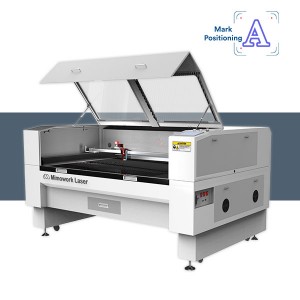

Marking all over your place

Technical Data

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

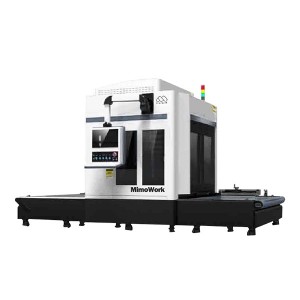

(Upgrade Power for your laser cutting machine for textile garment)

R&D for Textile and Fabric Laser Cutting

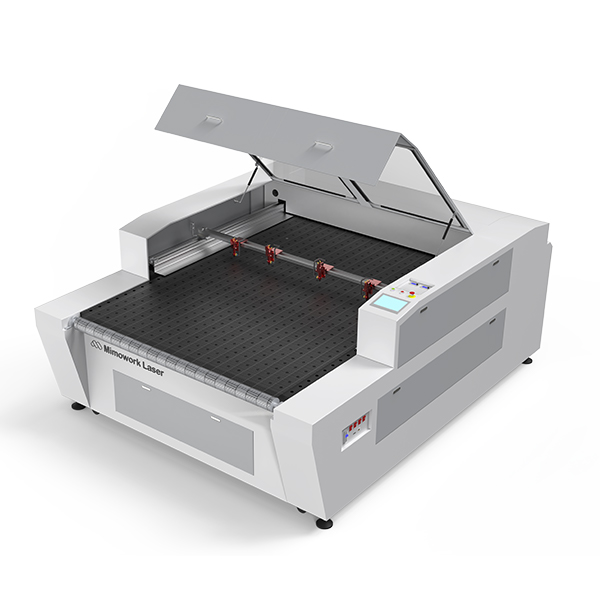

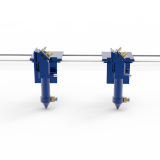

Two Laser Heads

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

Video Glance

Denim Fabric Laser Cutting

Find more videos about our laser cutters at our Video Gallery

How to cut sandpaper with a laser cutter

Fields of Application

Laser Cutting for Your Industry

Customized Marking

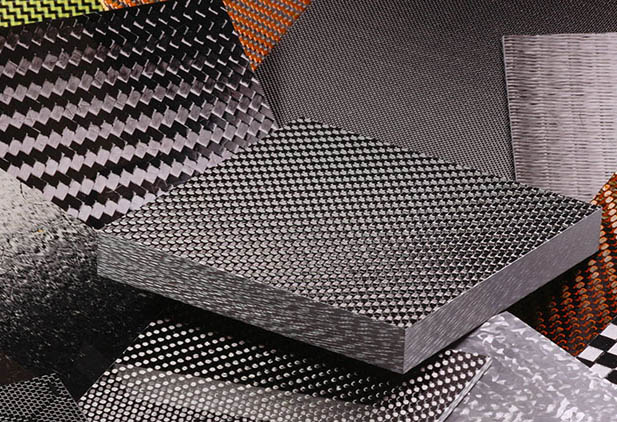

Composite Material

Engraving, marking, and cutting can be realized in single process

We’ve designed laser systems for dozens of clients

Add yourself to the list!

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Factory source China Flatbed Paper Label Sticker Die Cutting Machine with Hot Foil, We consider you will be contented with our fair rate, good quality items and fast delivery. We sincerely hope you can give us an option to serve you and be your ideal partner!

Factory source China Die-Cutting Machine, Die Cutter, Corporate goal: Customers’ satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

Nylon Laser Cutting

Professional and qualified Laser Cutting solution for Nylon

nylon-04

Parachutes, activewear, ballistic vest, military clothing, the familiar nylon-made products all can be laser cut with the flexible and precise cutting method. Non-contact cutting on nylon avoids material distortion and damage. Thermal treatment and accurate laser power deliver dedicated cutting results for cutting nylon sheet, ensuring clean edge, eliminating the trouble of secondary burr-processing. MimoWork laser systems provide customers with suitable customized laser solutions for different requirements(various nylon variations, different sizes, and shapes).

How to cut Nylon with the Fabric Laser Cutting Machine?

CO2 laser source with 9.3 and 10.6 micron wavelength is prone to be partly absorbed by nylon materials to melt the material by photothermal conversion. Additionally, flexible and varied processing methods can create more possibilities for nylon articles, including laser cutting and laser engraving. Inherent processing feature of laser system has been no stopping the pace of innovating for customers’ more demands.

Laser processing for Nylon

laser-cutting-nylon-01

1. Laser Cutting Nylon

Cutting nylon sheets to size within 3 steps, the CNC laser machine can clone the design file to 100 percent.

1. Place the nylon fabric on the working table;

2. Upload the cutting file or design the cutting path on the software;

3. Start the machine with the appropriate setting.

2. Laser Engraving on Nylon

In industrial production, marking is a common requirement for product type identification, data management, and affirming the right location to stitch the next sheet of material for a follow-up procedure. Laser engraving on nylon materials can perfectly solve the trouble. Importing the engraving file, setting the laser parameter, pressing the start button, the laser cutting machine then engrave the drill hole marks on the fabric, to mark the placement of things like Velcro pieces, to later be sewn on top of the fabric.

laser-perforating-nylon-01

3. Laser Perforating on Nylon

Thin but powerful laser beam can fast perforate on nylon including blended, composite textiles to conduct dense and different sizes & shapes holes, while no any materials adhesion. Tidy and clean without post-processing.

Why laser cut nylon sheet?

clean-eage-cutting-01

Clean edge for any angles

fine-small-holes-perforating

Fine small holes with high repeataion

large-format-cutting

Large format cutting for customized sizes

✔ Sealing the edges guarantees clean and flat edge

✔ Any pattern and shape can be laser cut

✔ No fabric deformation and damage

✔ Constant and repeatable cutting quality

✔ No tool abrasion and replacement

✔ Customized table for any size of materials

Material information of Laser Cutting Nylon

nylon-02

Firstly successfully being commercialized as synthetic thermoplastic polymer, nylon 6,6 are launched by DuPont as military clothing, synthetic textiles, medical devices. With high resistance of abrasion, high tenacity, rigidity and toughness, elasticity, nylon can be melt-processed into different fibers, films, or shape and play versatile roles in apparel, flooring, electrical equipment and molded parts for automotive and aviation. Combined with blending and coating technology, nylon has developed many variations. Nylon 6, nylon 510, nylon-cotton, nylon-polyester are taking on responsibilities in various occasions. As an artificial composite material, nylon can be perfectly cut on Fabric Laser Cut Machine. No worry about material distortion and damage, laser systems featured by contactless and forceless processing. Superior colorfastness and dying for varieties of colors, printed and dyed nylon fabrics can be laser cut into accurate patterns and shapes. Supported by Recognition Systems, laser cutter will be your good helper in processing nylon materials.

Other terms of Nylon

CORDURA®, Kevlar®, Polyester, Composite Materials