Coated Fabric Laser Cutter

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Coated Fabric Laser Cutter, We sincerely hope to determine some satisfactory interactions along with you from the in the vicinity of long run. We’re going to hold you informed of our progress and anticipate building steady company relations along with you.

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Coated fabric laser cutter, coated fabric laser cutting, Fabric Laser Cutter Machine, fabric laser cutting, fabric pattern cutting machine, industrial fabric laser cutting machine, laser cloth cutter, laser cut on fabric, laser engrave fabric, laser etch fabric, Textile Laser Cutting Machine, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

Advantages of Flatbed Laser Cutter

A Giant Leap in Productivity

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

R&D for Flexible Material Cutting

Two Laser Heads

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

2-min Overview of Laser Cutting Felt

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Clothing & Home Textiles

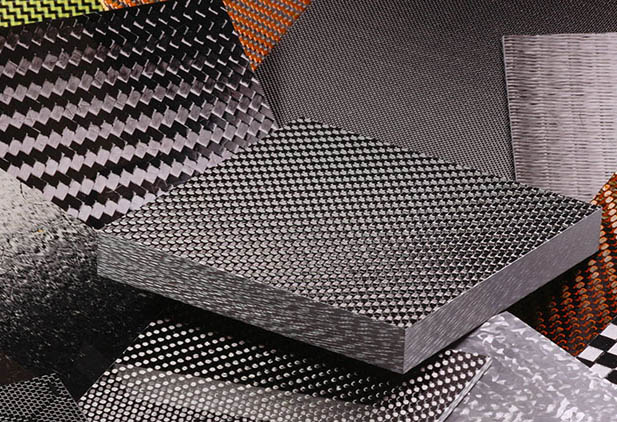

Composite Material

Engraving, marking, and cutting can be realized in single process

Automotive & Aviation

Your popular and wise manufacturing direction

Outdoor Equipment

The secret of exquisite pattern cutting

Common materials and applications

of Flatbed Laser Cutter 160

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Special Design for China Leather/Fabric/Cloth/Textile Cutting Machine for Garment/Shoes Upper/Handbag/Belt Making with Vibrating Cutter, We sincerely hope to determine some satisfactory interactions along with you from the in the vicinity of long run. We’re going to hold you informed of our progress and anticipate building steady company relations along with you.

Laser Cutting Coated Fabric

Professional Laser Cutting Solution for Coated Fabric

Coated fabrics are those that have undergone a coating procedure to become more functional and hold the added properties, such as cotton fabrics becoming impermeable or waterproof. Coated textiles are used in a variety of applications, including blackout curtains and the development of waterproof fabrics for raincoats.

The key point for coated fabrics cutting is the adhesion between the coating and substrate material may be damaged during cutting. Fortunately, characterized by non-contact and forceless processing, the laser cutter can cut through the coated fabrics without any materials distortion and damage. Facing different formats and varieties of coated fabrics, MimoWork explores customized laser machines and laser options for diverse production demands.

Benefits from Laser Cutting Coated Fabric

✔ Sealed edge from thermal treatment

✔ No deformation and damage on fabric

✔ Flexible cutting any shape and size

✔ No mold replacing and maintenance

✔ Precise cutting with the fine laser beam and digital system

Typical applications for coated fabric laser cutting

• Tent

• Outdoor equipment

• Raincoat

• Umbrella

• Industrial fabric

• Awning

• Curtain

• Working cloth

• PPE (Personal Protective Equipment)

• Fire-proof suit

• Medical equipment