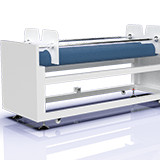

Flatbed Laser Cutter 160

◉ Flexible & quick cutting:

Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Popular size for multiple materials:

Standard 1600mm * 1000mm is accord with most materials formats like fabric and leather (working size can be customized)

◉ Safe and stable laser structure:

Upgraded cutting stability and safety - improved by adding the vacuum suction function

◉ Automatic production - less labor:

Automatic feeding and conveying allow unattended operation which saves your labor cost, lower rejection rate (optional)

Mark pen makes labor-saving process and efficient cutting and materials labeling operations possible

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Servo Motor Upgrade Available

(As your garment laser cutter, leather laser cutter, lace laser cutter)

R&D for Laser Cutting Fabric

Two / Four / Multiple Laser Heads

Customize Your Laser Cutter Machine

MimoWork is here to help you with laser advice!

Video Display of Textile Laser Cutting

Dual Heads Laser Cutting on Denim

• With the help of auto-feeder and conveyor system, the roll fabric can be fast conveyed to the laser table and making preparation for the laser cutting. Automatic process greatly enhance the efficiency and lessen the labor cost.

• And the versatile laser beam features excellent the penetration power through the fabrics (textiles), allowing the flat and clean cutting quality in short time.

Details Explanation

you can see the smooth and crisp cutting edge without any burr. That is incomparable with the traditional knife cutting. Non-contact laser cutting ensures being intact and undamaged for both fabric and laser head. Convenient & safe laser cutting becomes ideal choice for the apparel, sportswear equipment, home textiles manufacturers.

Fields of Application

Laser Cutting for Your Industry

Common materials and applications

of Flatbed Laser Cutter 160

Materials: Fabric, Leather, Cotton, Nylon, Film, Foil, Foam, Spacer Fabric, and other Composite Materials

Applications: Footwear, Plush Toys, Garment, Fashion, Garment Accessories, Filter Media, Airbag, Fabric Duct, Car Seat, etc.

✔ Smooth and lint-free edge through heat treatment

✔ Conveyor system helps more efficient production for the roll materials

✔ High precision in cutting, marking, and perforating with fine laser beam

Engraving, marking, and cutting can be realized in single process

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Fewer material waste, no tool wear, better control of production costs

✔ Ensures a safe working environment during operation

Your popular and wise manufacturing direction

✔ Smooth and lint-free edge through heat treatment

✔ High quality brought by fine laser beam and contact-less processing

✔ Greatly saving cost to avoid materials waste

The secret of exquisite pattern cutting

✔ Realize unattended cutting process, reduce manual workload

✔ More customization from high-quality value-added laser treatments like engraving, perforating, marking, etc

✔ Customized laser cutting tables meet requirements for varieties of materials formats