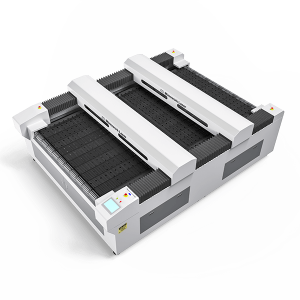

Cordura Fabric Laser Cutting Machine

High-quality comes 1st; support is foremost; business is cooperation” is our small business philosophy which is regularly observed and pursued by our organization for Cordura Fabric Laser Cutting Machine, We invites you and your company to thrive together with us and share a dazzling foreseeable future in world-wide market place.

High-quality comes 1st; support is foremost; business is cooperation” is our small business philosophy which is regularly observed and pursued by our organization for Cordura 1000D cutting, Cordura backpack, cordura backpack laser cutting, cordura fabric laser cutter, cordura fabric laser cutting, cordura laser cut, Cordura nylon, Cordura seat cover, cutting cordura by laser, fabric laser cutter, fire-resistant coated Cordura fabric, how to cut cordura fabric, laser cutter for cordura fabric, laser cutter price, Laser Cutting Fabric, laser cutting machine price, laser engraving machine price, laser marking machine price, laser marking on cordura fabric, nylon fabric laser cutting machine, “Good quality and reasonable price” are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

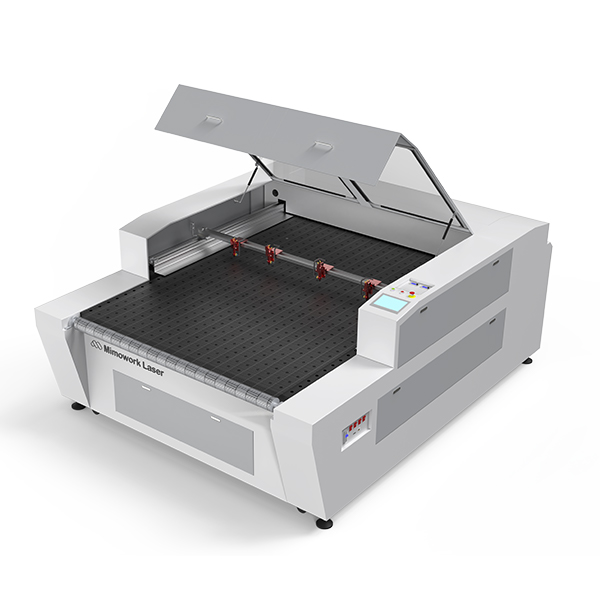

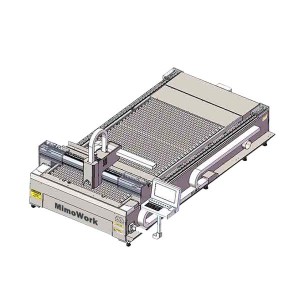

Advantages of Flatbed Laser Cutter

Marking all over your place

Technical Data

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

R&D for Flexible Material Cutting

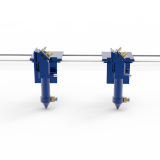

Two Laser Heads

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

Video Overview of Laser Cutting & Perforating on Sandpaper

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

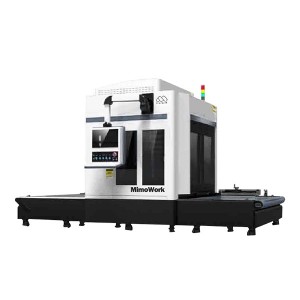

Customized Marking

Composite Material

Engraving, marking, and cutting can be realized in single process

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Factory Selling China CO2 Laser Cutting Machine, CO2 Laser Engraving Machine, “Good quality and reasonable price” are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

Laser Cutting Cordura®

Typical applications for Laser Cutting Cordura® Fabrics

• Cordura® Patch

• Cordura® Package

• Cordura® Backage

• Cordura® Watch Strap

• Cordura® Bag

• Cordura® Motorcycle Pants

• Cordura® Seat Cover

• Cordura® Jacket

• Ballistic Jacket

• Cordura® Wallet

• Protective Vest

Benefits from Laser Cutting on Cordura® Fabrics

High repeatation precision & efficiency

Clean and sealed edge

Flexible curve cutting

✔ No material fixation due to the vacuum table

✔ No pulling deformation and performance damage with laser force-free processing

✔ No tool wear with laser beam optical & contactless processing

✔ Clean and flat edge with heat treatment

✔ Automated feeding and cutting

✔ High efficiency with conveyor table from feeding to receiving

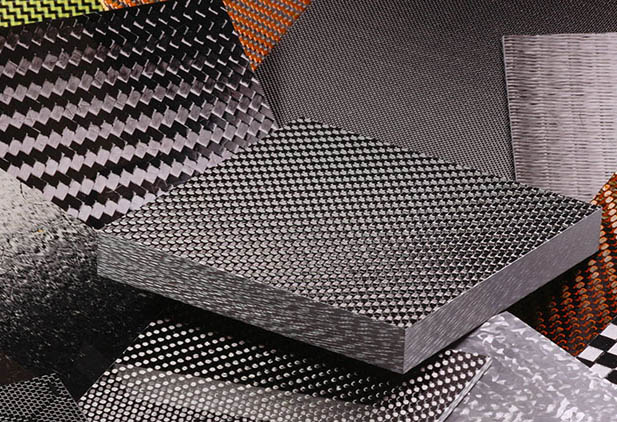

Material information of Laser Cutting Cordura®

Usually made of nylon, Cordura® is regarded as the toughest synthetic fabric with unparalleled abrasion resistance, tear-resistance, and durability. Under the same weight, the durability of Cordura® is 2 to 3 times that of ordinary nylon and polyester, and 10 times that of ordinary cotton canvas. These superior performances have been maintained so far, and with the blessing and support of fashion, infinite possibilities are being created. Combined with printing and dyeing technology, blending technology, coating technology, versatile Cordura® fabrics are given more functionality. Without worry about materials’ performance being damaged, laser systems own excellent advantages on cutting and marking for Cordura® fabrics. MimoWork has been optimizing and perfecting laser cutter and laser marker to help manufacturers in the textile field update their production methods and obtain maximum benefit.

Related Cordura® Fabrics in the market:

CORDURA® Ballistic Fabric, CORDURA® AFT Fabric, CORDURA® Classic Fabric, CORDURA® Combat Wool™ Fabric, CORDURA® Denim, CORDURA® HP Fabric, CORDURA® Naturalle™ Fabric, CORDURA® TRUELOCK Fabric, CORDURA® T485 Hi-Vis FABRIC